High productivity and flexibility solution due to the "Flexy pin" system that eliminates panel composition down-times and avoids the stocking of counter shape.

Press configuration up to 3 trays to maximize productivity by reducing cycle time to the pressing time.

Finished product quality and high definition even with complex 3d surfaces are granted thanks to the intermediate flange and the possibility to reach high specific pressures. the frame ensures sturdiness in each working phase even with the most demanded machining cycle.

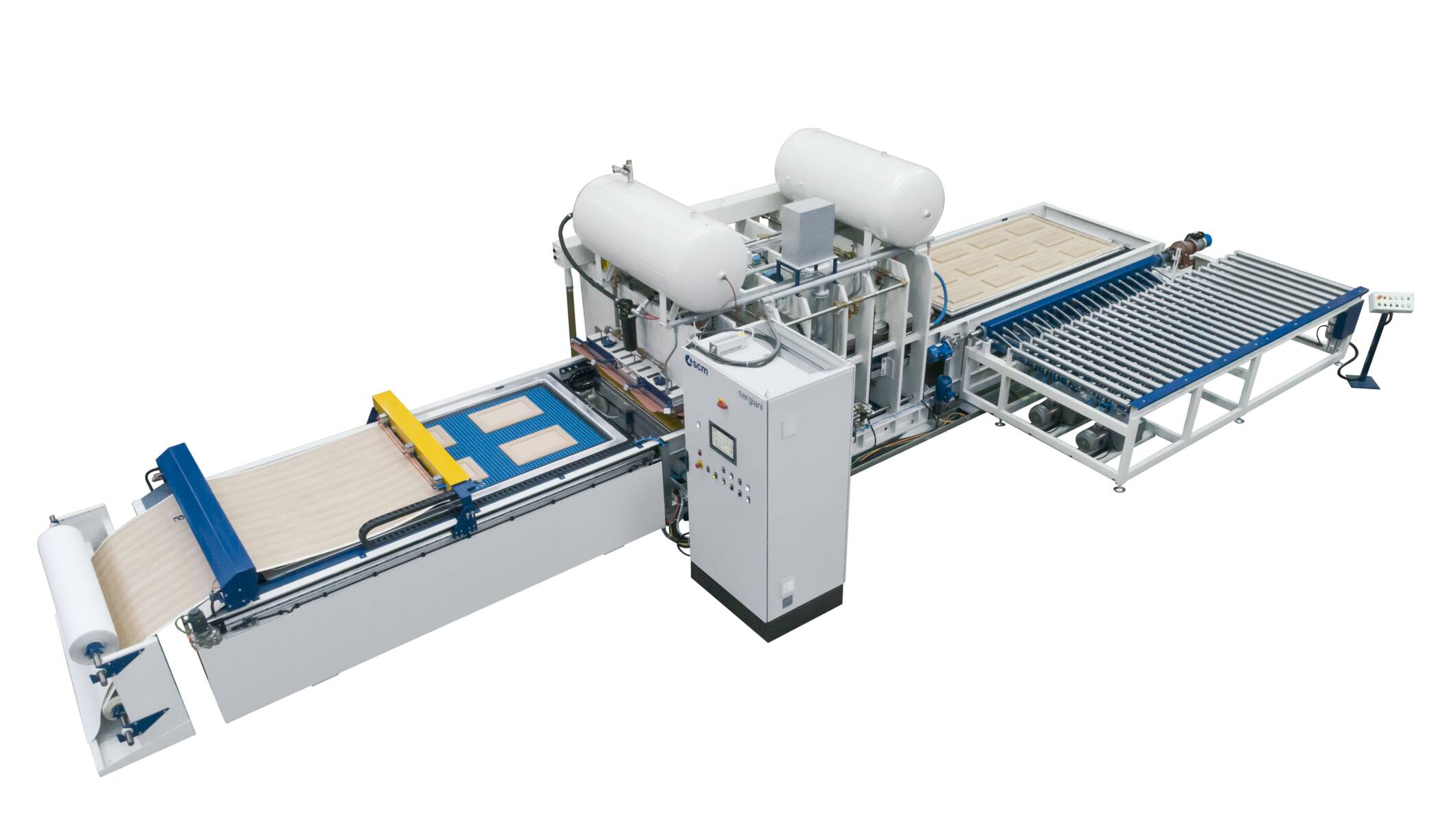

AUTOMATIC FLEXY PIN SYSTEM

Maximum flexibility and fast tray composition due to the AUTOMATIC "FLEXY PIN" SYSTEM that avoids the use and storage of counter shape by reducing cycle downtime in manual composition systems.

3 TRAYS CONFIGURATION

Maximum productivity due to the possibility to add up to 3 trays that reduces the cycle time to just the pressing time.

Completely automatic trays handling and in synchrony with the loading/unloading units.

INTERMEDIATE FLANGE

High definition even with complex shapes due to the vacuum circuit and the air under pressure in the intermediate flange. The vacuum cycle brings the membrane into contact with the coating reducing the risk of creasing and improving the uniformity of the PVC heating. Moreover, thanks to the second pressing cycle, which introduces air under pressure directly from the flange, it is possible to obtain a better definition even with particularly complex shapes.

| Model | Platens dimension (mm) | Thrust (ton) | N° cylinders x diameter (mm) | Working chamber height (mm) | Specific pressure (kg/cm2) | Type of structure |

|---|---|---|---|---|---|---|

| 3d form hp 25-14 | 2340x1340 | 200 | 4 x140 | 60 | 5+1 | assembled beams |

| 3d form hp 30-14 | 2840x1340 | 300 | 6 x140 | 60 | 6+1 | |

| 3d form hp 33-14 | 3200x1340 | 400 | 8 x140 | 60 | 6+1 | |

| 3d form hp+ 30-14 | 2900x1340 | 400 | 8 x140 | 60 | 8+1 | ribbed |

| 3d form hp+ 33-14 | 3200x1340 | 500 | 10 x140 | 60 | 8+1 |

Wypełnij ten formularz, aby uzyskać więcej informacji