sergiani 3d form

(512) 931-1962

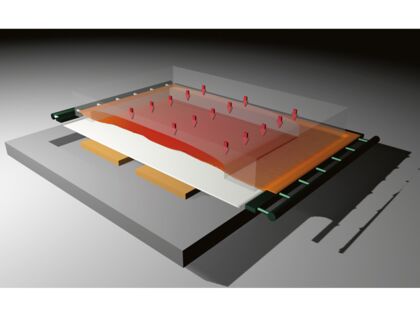

Press for 3D panels laminating, both with veneer and pvc or abs. Membrane or membrane-less woring cycle, with coupled operation of the depressure/pressure cycles depending on the product to press.

INTERMEDIATE FLANGE

High definition even with complex shapes due to the vacuum circuit and the air under pressure in the intermediate flange. The vacuum cycle brings the membrane into contact with the coating reducing the risk of creasing and improving the uniformity of the PVC heating. Moreover, thanks to the second pressing cycle, which introduces air under pressure directly from the flange, it is possible to obtain a better definition even with particularly complex shapes.

MANUAL PIN

They are placed on a magnetic net that eases and reduces the platen composition time. This system avoides the support panels stocking that are used as counter-shapes and consequently the related management and maintenance costs.

| 3d form 25 - 14 | 3d form 30 - 14 | 3d form CA 25 - 14 | 3d form CA 30 - 14 | 3d form CA 32 - 14 | ||

| Platens dimensions | mm |

2340x1340 |

2840x1340 |

2340x1340 |

2840x1340 |

3200x1340 |

| Max. panel dimensions | mm |

2240x1240 |

2740x1240 |

2240x1240 |

2740x1240 |

3100x1240 |

| Thrust | ton |

200 |

300 | 200 | 300 | 500 |

| Working chamber height | mm | 60 | 60 | 60 | 60 | 60 |

| Pressure | kg/cm2 | 5 | 5 | 5 | 5 | 8 |

| Pistons | 4-140 | 6-140 | 4-140 | 6-140 | 8-140 |

Wypełnij ten formularz, aby uzyskać więcej informacji