In Nantes we visit a company specialised in fitting commercial vehicles. MDP has focussed in this sector with 6 SCM work centres, purchased between 2004 and 2016. “After training as a joiner, I was looking for an idea to fulfil myself”, explains Pascal Dabireau, company manager. “I therefore leased a part of my father’s plant to develop a range of products to fit commercial vehicles. In 1990 I began the business and, after an initial period with some difficulties, everything worked out well…”.

After starting with a Renault Express, MDP now fits numerous brands of commercial vehicles and is a reference point for various car manufacturers (Renault, Ford, Opel, Nissan and Renault Trucks). "The company works in shifts (in 3/8) and counts on an integrated design office”, continues Pascal Dabireau. “We employ 45 people and about a dozen temporary workers to fit 28,000 vehicles a year."

Split between two sites, a few hundred metres from each other, the MDP production is manufactured just-in-time in order to limit stockpiling.

“We work with two days’ notice and very tight deadlines, with only seven days from order to delivery. This is why we need an advanced, up to date and super-efficient machine inventory. Today the machines include integrated loading and unloading systems, that help us save time and space in our plants. We constantly follow the latest technical innovations to further optimise our production”.

Reduced material waste, but especially more units produced per kWh, was some important issues for Dometic, who has sustainability as one of their focus issues. But in the end it was the responsiveness together with the fact that the offer from S.I.T. was the one giving most value for money, that decided their choice. Also, both Mats Borg and Daniel Bergåker, process technician at Dometic Seitz, praises the response from S.I.T. both during the procurement process and the installation.

"They have showed an ability to really listen to us and give response to what we needed and was looking for", says Daniel Bergåker.

MDP does not simply machine the panels, it also finishes them by painting 100% of its production. “We had this idea in 2010. Beforehand we installed unfinished panels in the finished vehicles, but the aesthetic results weren’t optimum”.

Once machined and painted the parts are fitted to reduce the operating times and allow a Kangoo to be fitted in “10 or 15 minutes”. An attention to detail that has been the hallmark of the company’s success, which enjoyed double digit growth in 2016 (12 million for MDP and 1.5 million for MDP finishing).

In 2017, MDP wants to maintain its growth with “at least +15% in turnover and new investments to complete the machine stock”, in order to continue fitting with wood the commercial vehicles of its 3.500 customers.

Source: magazine Bois Mag

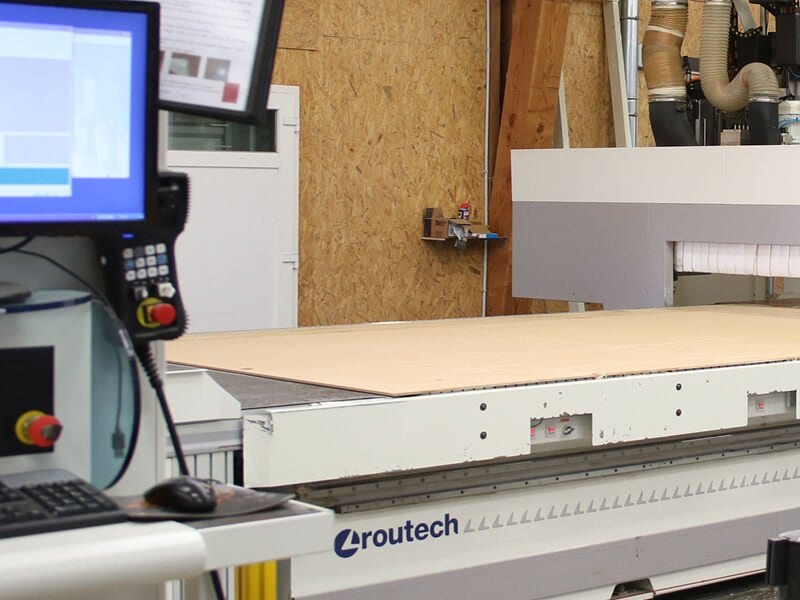

"We have a continued strong increase in volume, so in spite of efficiency improvements with the new CNC milling machine, we have to reintroduce weekend shift to manage the production, says Mats Borg. So I don’t think it is impossible that there will be another Routech Ergon from S.I.T. here in the future", Mats Borg concludes.

Ergon R400 TVN is a special solution designed and produced in the Routech plant of the SCM. It is a work centre with double bar table, each one with a useful area of 2850x1850 mm. Specific hold-down equipment ensure the perfect finishing quality of the client’s pieces: car windows, in specially shaped methacrylate. On each table the routing and drilling operations are carried out by a 5-axes machining unit. Therefore two machining units in total that can operate in parallel or independently, to fulfil all productivity and flexibility requirements.

Wypełnij ten formularz, aby uzyskać więcej informacji