Fabbrica Mirlachova

Furniture Technologies

Russia on the move

The exemplary story of Andrey Mirlachov, a “self-made man” who has created a model company, employing 250 people, producing state of the art, high quality furniture. A man with very clear ideas: “In terms of technology I only want the best”, which naturally led him to SCM. The plant has a cell designed to guarantee quality and flexibility. In the Russian tradition the furniture bears his name: “I denied myself the possibility of producing poor quality furniture”.

Andrey Mirlachov’s life and entrepreneurial journey runs parallel to the journey of new Russia, that with pride has returned to playing a leading role in the globalised world. In 1995 the young Andrey completed his military service and found himself in a Russia that had completely changed. The market economy was taking hold with a chaotic capitalism. Mirlachov started working in countless different jobs before being hired, as if by fate, as joiner in a furniture company making sofas. This experience was “his university”: there were no work centres, the boards weren’t even dried and sprayed water everywhere. It was a time that was defined as “garage assembly”. But the market was strong and people queued up to buy new furniture and companies made enormous profits. Andrey first became team leader, then department manager and everything seemed to be proceeding perfectly, until in 1998 the market, coming up against a globalised word, collapsed. The factory closed and all the employees were sent home. Mirlachov didn’t give in and used his experience to plunge headlong into another venture. In Udmurtia, 9 kilometres from Izhevsk, he rented a department with machinery from a company that had stopped operating and started producing sofas. In 1999 his first son was born and naturally the first product, a sofa-bed for children with a sliding mechanism that is still in production, was named after him: Dania.

The product was a success and Andrey could start thinking about a new company. In 2000 the first employee was hired, his father, to look after shipments, and then his sister, who from kindergarten teacher became responsible for the sewing department. Then he hired his wife and in 2004 his cousin, who was put in charge of the administration. A typical family run company that in 2005 became “Fabbrica Mirlachova”. Naming the company was a difficult decision for Andrey, who felt it was immodest to call the company with his name. But a friend’s insistence won him over: “With your name you become personally responsible for the quality of the product. For centuries manufacturers in Russia have worked this way”. And so Andrey decided for his name even though to this day he jokes about it: “With that choice I denied myself the possibility of producing poor quality furniture!”.

This was the beginning of a company in Udmurtia that currently employs 250 people and produces wardrobes, sitting rooms, beds and kitchens with great personality. The reference market, thanks to the use of exclusive fabrics, original combinations and bright colours is young, active and modern; the most dynamic part of the new Russia. The furniture is shipped in well-made kits and is simple to assemble.

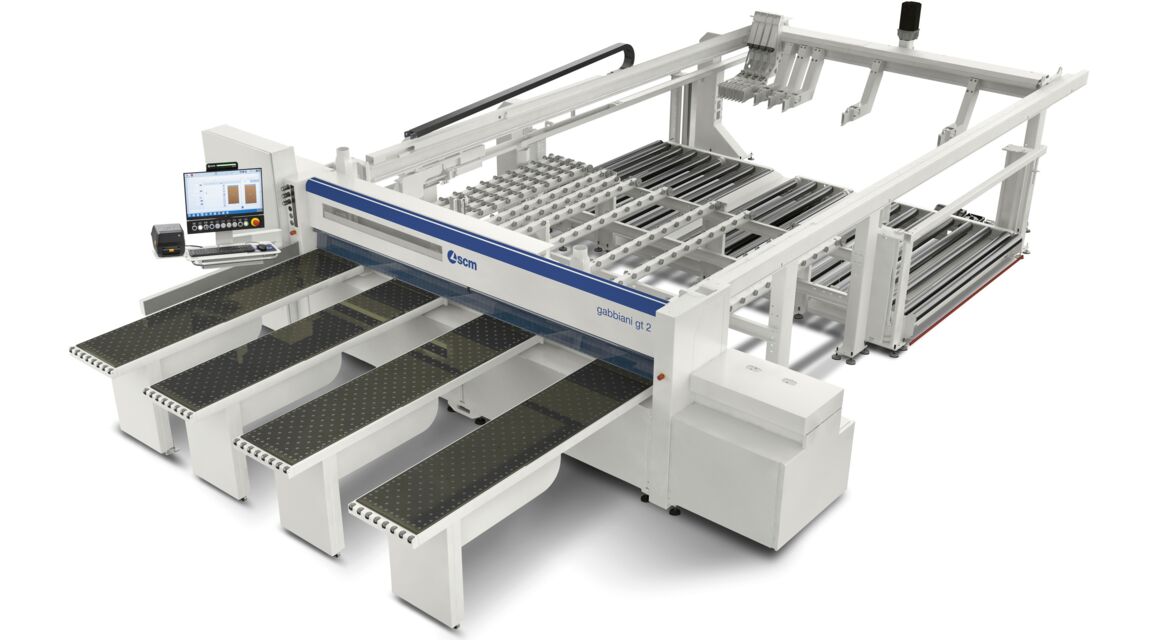

The company’s guidelines have always been clear: seeing his past experiences Mirlachov won’t compromise, he wants the best technology available. This led him to contacting the largest companies in the escort to understand what the latest machines were and which ones were more suited to his production. He chose SCM’s solutions. Andrey explains that his colleagues often criticised him for his obsession with having extremely technological machines: “At the beginning we may not have been able to use 100% of the solutions that we had available, but for me it was always clear that I was investing for the future. They provided us with the right potential for growing. I was the first in Udmurtua to buy a nesting machine, a drilling unit, a quilting machine and a panel sizing centre. Only now do the others think about these technologies, whilst I have been using them to their full potential for some time and I am already thinking about the next steps”. There is something that guides Mirlachov’s choices: the machines don’t have to be merely functional they must also be beautiful. He believes that a company’s aesthetic aspect is of great importance. This is why Fabbrica Mirlachova, which covers an area of two hectares, is a model company where the concepts of industrial design are applied and where everything must be beautiful and where workers must be happy and be able to work safely and in comfort. SCM machines are an integral part of this “beautiful factory”.

Finally the panels are sent to the drilling section with the Morbidelli Cyflex and Morbidelli Uniflex, whose work programs can be changed at an instant and can handle individual orders.

Uniflex is the drilling unit with the highest productivity levels, as it can machine two panels at the same time and is the driving force of this department. The Cyflex on the other hand machines single pieces in “batch 1” and also small sized pieces. The company works in batches of 1 to 300 pieces. Thanks to the numerical control technologies Fabbrica Mirlachova produces high quality products without giving up production flexibility, which means being able to quickly change the type of production, increase or decrease the number of batches being produced based on market demands.

Once they come out of the production line the individual pieces are finished and cleaned. The kits are packed and sent to the packaging unit that operates automatically.

There are no holds barred in the globalised market, but Andrey Mirlachov accepts the challenge willingly and with courage: “Our approach is based on quality: each part of the furniture that we make has our name on it. Our levels of quality are acknowledged by our German and Italian friends, and perhaps one day we may even sell in these markets: I am confident”.

Text and pictures by Maxim Pirus, editor in chief LesPromInform

Fabbrica Mirlachova (Russia)

High quality furniture manufacturer

www.mirlachev.ru

Fill out the online form to be contacted by a salesperson