Beam saw

gabbiani gt2 with articulated robot for automatic loading and unloading: flexible cell that optimises shifts and promotes the needs of machining that is both "batch 1" and based on large volumes. It can be used with or without the articulated robot, with automatic switch from one modality to another. All this enhanced by the new Maestro optiwise optimiser.

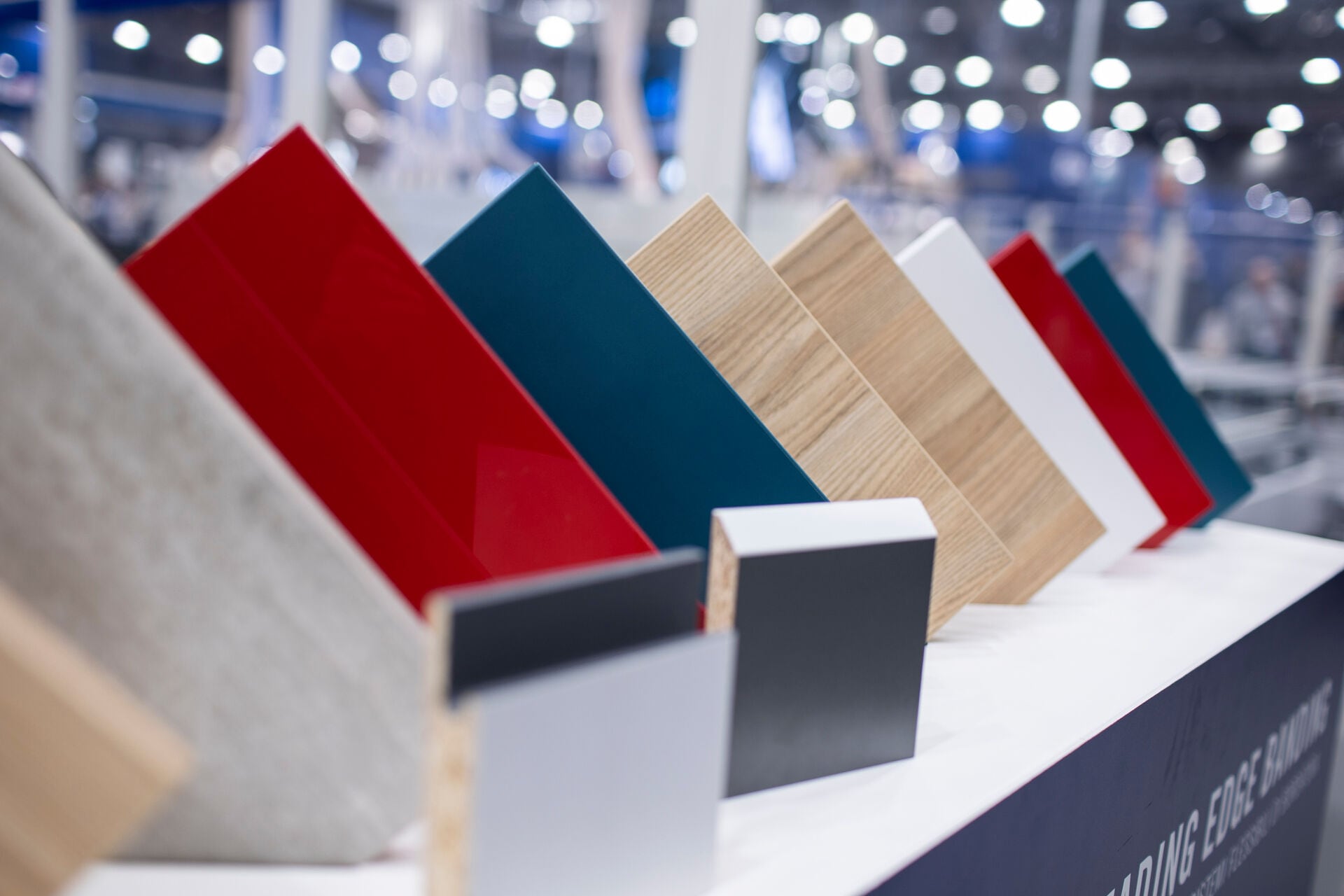

Edge banding

stefani cell E: flexible cell that combines the advantages of a production of exceptional quality with those of a complete automation at 25 metres per minute. The panels are loaded autonomously by an articulated robot. At the exit, the pickback bridge system guarantees the timely return of the machined panels. All this with a simple and intuitive control thanks to HMI Maestro active edge software.

Drilling

morbidelli cx220: flexible drilling and dowelling cell with robot to produce all furniture elements more efficiently, even with workpieces that differ considerably from one another. The cell produces one panel per minute and over 400 panels per shift, with one operator, in 50 m2. It can be used exclusively with the robot for a continuous cycle production, or with partial operator supervision.

Packing

cut c200: a new solution for "batch 1" cardboard box packaging to produce up to 4 boxes per minute in different shapes and sizes. The ideal solution for optimising the use of cardboard based on the actual product size.

Sizing

class px 350i: circular saw with mobile saw carriage with a up to 46° tilting blade that allows the maximum safety when working and perfect panel clamping: Advanced technology with the SCM Thundercut Optimizer/Sequencer, unique in driving the operator step by step when inserting the panel into the machine and in cutting.

Edgebanding

me 40: automatic edge bander with the new eye-S compact control panel with Maestro active interface for optimal machine management. The control manages the new on/off system for the operating units and graphically represents all the machine functions.

Drilling

startech cn plus: CNC drilling centre designed to easily and flexibly produce furniture parts without repositioning the tools and without a need for operator-intervention.

Data preparation

The updated CAD/CAM office programming software for Maestro cnc machining centres and the 3D Maestro pro view simulator for machining panels and solid wood will be on display at Ligna.

Planning, optimisation and production control

Production

The HMI software and Maestro active line supervisors have also been updated for an even simpler, optimal control and interaction with all of SCM's machines.

Monitoring production, machine maintenance and after-sales assistance

The digital services enabled by the Maestro connect IoT platform are further enhanced to guarantee maximum performance in the machines and plants in sync with the constant support provided by SCM's technicians.

oikos xs: maximum implementation speed, precision and reduced footprint are the advantages of this new CNC machining centre designed for the production of prefabricated walls, trusses, roofs and blockhaus.

Maestro active beam&wall: thanks to SCM’s new HMI software, control and optimisation of the production flow directly on the machine are now even simpler and more intuitive.

dmc system xl: highly modular automatic sanding-calibrating machine, capable of machining CLT panels up to 3700 mm in width and 500 mm thick.

At the SCM stand in Hall 13, you will have a chance to discover the new laser unit applied to dmc system automatic sanding-calibrating machines, for three-dimensional marking on parquet, wooden elements, mdf panels to be veneered, fibre cement panels and solid surfaces. Thanks to the exclusive "Self-Refilling" technology, it is possible to make the most of the features in terms of power without interrupting the production flow.

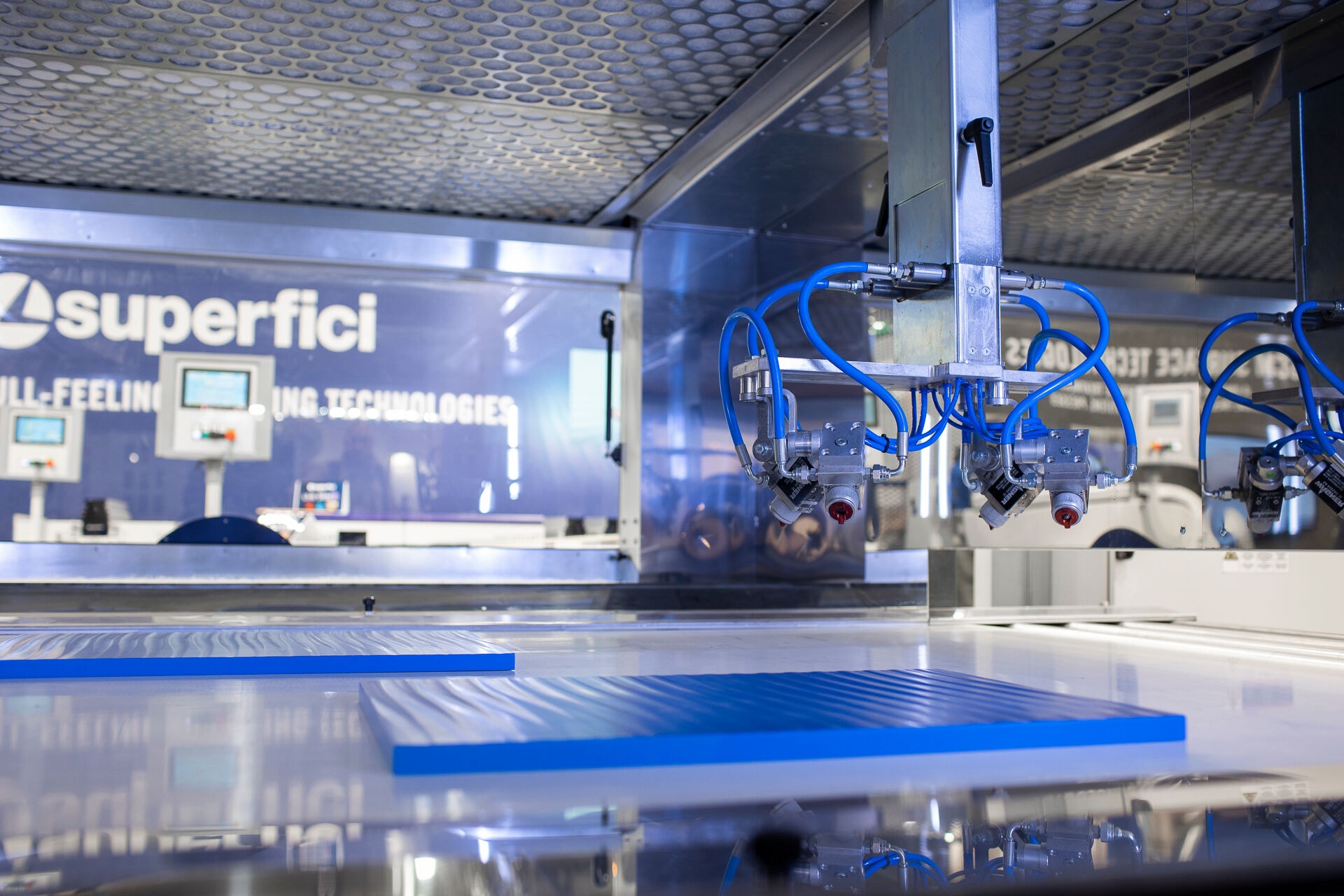

The latest products for finishing are also on display at the Superfici stand (Hall 16, stand C6-D5).

- compact xl: spray for high productivity levels, provides a system to save paint more effectively and an advanced recycling of air volume.

- Uv led polymerisation system with more monochromatic UV sources with different wavelengths: for performance that is fully comparable with conventional UV polymerisation, while maintaining the advantages of led.

- Excimatt: Superfici's excimer technology for the finishing on the widest range of finished products and materials: to add incredibly smooth extra-matte effects with no more compromising on the surfaces' resistance.

Linking up from the Technology Center in Rimini, the new sizing and nesting cell ideal for "batch 1" with flexstore hp automatic storage and articulated robot for unloading finished pieces, small pieces and discarded pieces. gabbiani p80 beam saw and morbidelli x200 nesting machining centre are both integrated into the automatic warehouse that ensures storage, automatic labelling of the panels and direct loading onto the worktable of both machines, to protect the more delicate surfaces. Simultaneously, the gabbiani p80 beam saw can also perform pack cutting with exceptional production levels.

New FlexDrive worktable available on the Machining Centre for routing and drilling morbidelli m100: no set-up mistakes thanks to this innovative system based on LED light indicators that guide the operator by indicating the exact position of the bars and locking systems.

Nesting Machining Centre for routing and drilling morbidelli x200 with in-cab labeller: unique SCM device that allows automatic label printing even without a complete cell, creating an economic and automated system that doesn't require operator supervision.

New entry also for edgebanding with olimpic 500, dedicated to the artisan business and complete with new, large touch control to make for easy, intuitive use and a connection with company management systems. It is also ideal for producing drawers and offers the possibility of machining panels with a thickness of up to 60 mm, even in rounding.

And for large industries, the new stefani sbx squaring-edgebanding machine will be displayed digitally: the most advanced SCM technological innovations for this sector: these include Servo electronic units and other solutions for high productivity levels and excellent performance with every machining.

accord 500: CNC machining centre to produce windows, stairs and solid wood elements. It offers 30% higher productivity compared to market standards and an intelligent management with Maestro Power TMS.

hypsos: universal 5-axis CNC machining centre with integrated cabin, designed for interior decorators and the three-dimensional processing of elements with a complex shape or large dimensions.

celaschi cpm: single-sided profiling machine designed to process elements of cabinet doors. Among the advantages are an operating unit made up of an electro-spindle with HSK attachment associated to an automatic 8-position tool store and an even more user-friendly operation, thanks to the new Maestro active square HMI software.

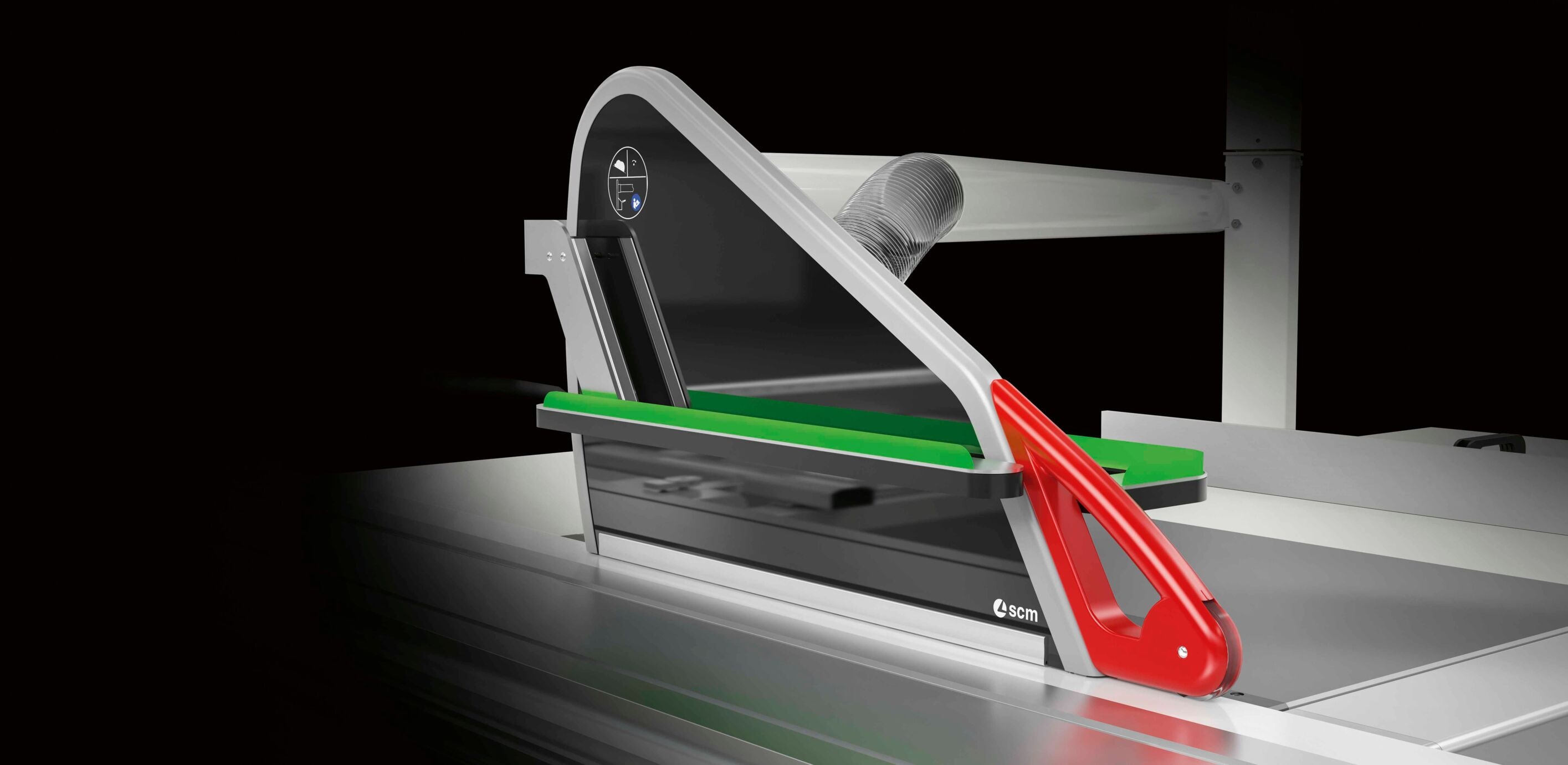

New “Blade Off” safety system. The innovative technological solution designed by SCM applied to the circular saws. It prevents accidental contact between the operator's hand and the blade. The system is equipped with smart sensors that can identify and recognise the human body and trigger the system even before the operator gets too close to the blade, protecting the danger zone around it.

New “Blade Off” safety system. The innovative technological solution designed by SCM applied to the circular saws. It prevents accidental contact between the operator's hand and the blade. The system is equipped with smart sensors that can identify and recognise the human body and trigger the system even before the operator gets too close to the blade, protecting the danger zone around it.

startech cn k: compact 3-axis NC machining centre ables to carry out all types of milling, decorations, engraving, signboard creation and 3D model prototyping. The only one in its category equipped with a 2,4 kW electrospindle. The integral cabin ensures absolute protection for the operator and keeps the surrounding environment clean. Very simple to be programmed, thanks to the "Open" virtual human-machine interface capable of importing G-code from any type of CAD / CAM software.