|

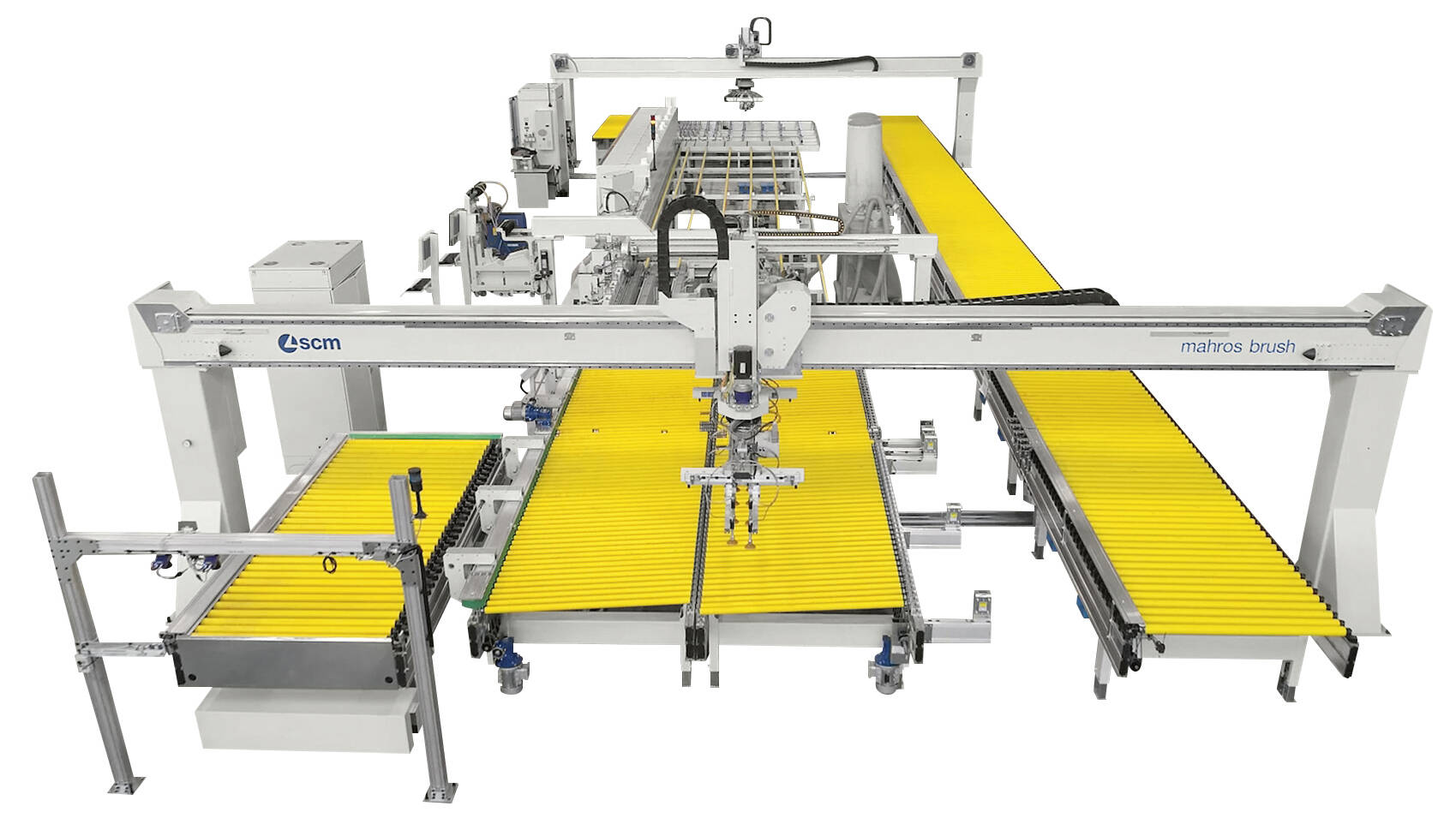

Machinable dimensions with lengthwise feeding

(length x width) (min/max)

|

mm | 320x130 / 3200x1600 |

|

Machinable dimensions with crosswise feeding

(length x width) (min/max)

|

mm | 120x260 / 1600x3200 |

| Operators | n° | 1 |

| Program change to Batch 1 (reading of unique code on panel by Bar Code / Qr Code) | - | YES |

| Possibility to size the panel | - | YES |

| Change of colour, thickness, edge protection film | - | YES |

| Panel dimension change | - | YES |

| Groove position and depth (in flexible mode) | - | YES |

| Glue dosage change | - | YES |

| Addition of a panel during Batch 1 machining | - | YES |

| Homogeneous panel management | - | YES |

| Closed loop management | - | YES |

| Panel re-machining | - | YES |

| Edge bander model | - | stefani one / stefani sb one |

Fill out the online form to be contacted by a salesperson