Tradition, innovation and technology are the pillars of this Romagnola company specialised in the production of buildings and elements for timber construction with a strong “green” imprint. One of its works is an architectural element, the structure supporting the vault and proscenium arch at the prestigious Galli Theatre in Rimini, and which was fundamental to the rebirth of the theatre.

A company with deep roots, solid like the quality raw material par excellence from which its creations stem. Since 1985, I.T.A.B has been transforming the extraordinary physical and mechanical properties of wood and considerable technological potentialities into customised and innovative solutions for construction, furnishings and design. In reality, taking a closer look at the family tree of this company, now in its third generation, we discover that its origins date back as far as the 1940s. We are at the heart of the Valmarecchia, in Ponte Santa Maria Maddalena, surrounded by the green hills between Rimini and Pesaro, a countryside perfectly in line with the sensations of warmth, harmony and naturalness that the wood naturally releases. The architectural features of the headquarters, covering a surface area of 13 thousand square metres, are in themselves the company’s first “business card”, a clear demonstration of I.T.A.B.’s strength to conjure up a passion for tradition using the most modern technologies. The structure, entirely made of wood, combines with eco-construction design techniques and modern furnishing, and decorative elements like the large glass display windows showing off the bright showroom from the outside. It is here that Gilberto Bucci, owner and partner together with his brother-in-law Adriano Tamburini welcomes us with daughters Laura, Elisabetta and Elena, all with the different roles and involved in running the family business. The other “pillar” in the business is Maria Tiziana Bucci, Adriano’s wife and sister to Gilberto, who has always been at their side, ready to make the accounts add up in the admin. office.

Gilberto has been working with wood since he was 13 years old, alongside his father Augusto, a carpenter, and the memory of whom still remains clear in the minds of many of the older clients. “A lot of people still ask us for a piece of furniture like grandfather Gutìn made!” Laura tells us, the granddaughter in the Bucci team with a head for “sales”. Overtime, in virtue of the considerable progress made in the timber building industry, the creation of eco-constructions with a high technological leaning and energy saving, has become “core business” at I.T.A.B. “We started out in the 1980s as a saw mill and over the years, we have further diversified our production - explains Gilberto - Nowadays, 50 per cent of our work is timber houses, roofs, coverings, timber frame walls (Platform) and X-lam (panels), mostly produced with pine and fir wood types”.

The production range is vast and highly varied: villas for private clients, residential complexes, prefabricated houses, beach and tourist-reception structures where the “green” imprint is increasingly more requested in light of new legal regulations governing earthquake-proof, fireproof and thermal-acoustic matters. And more, external wooden paving, ventilated façades, sports complexes, schools and industrial structures with dried fir wood strips, specifically checked and selected in the best parts to achieve greater elasticity and mechanical resistance. All that remains is the part dedicated to door and window frames and furnishings, without forgetting decorative objects that include attractive gifts. All managing to be practical and attractive to look at as well as being made-to-measure, the key to successfully rising above the competition which, nowadays, is increasingly tough.

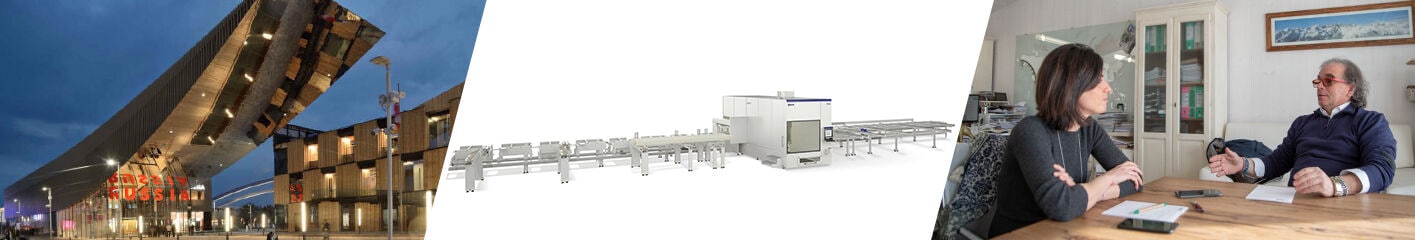

“The timber construction industry is flourishing - adds Gilberto - but it is quality that makes the difference. We present ourselves as a reference partner thanks to our careful selection of raw materials, solid craftsmanship experience, flexible approach, highly specialised in-house staff and state-of-the-art technological plants. In total, there are 26 of us, but we continue to expand and are in search of engineers to further reinforce our technical department. It all starts with the planning, design and data elaboration that is then transmitted to the numerical control machining centres which, nowadays, is at the heart of our factory, an oikos purchased from SCM in 2014 which has allowed us to diversify our production significantly. On the oikos we process structural beams, X-lam wall panels/CLT, even very large sized ones. As well as this advantage, the Maestro beam&wall software makes the operator’s job a lot easier thanks to the perfect integration with the main CADs for planning and the possibility of simulating and testing the work in advance which, will then be carried out on the machine. All this while constantly guaranteeing quality results”.

Oikos is not the only machine purchased from SCM. We also have a gabbiani s 90 saw (sigma impact 90 pre-rebranding) and a router for made-to-measure craftsmanship processing work. “We chose SCM for the soundness of its brand. Its technology helped us to manage the entire process internally and, above all, to become faster, better performing and more competitive” affirms Gilberto. Advantages which are just as fundamental for the owner of I.T.A.B. as the after-sales service received. On the other side, SCM made a question of meeting the specific needs of this company starting from its ability to create new production standards even in timber construction, in the name of eco-sustainability, safety and high technology.

We browse through the “made in I.T.A.B.” references album and even discover the Russian and French pavilions created for Expo Milano 2015 and the “Amintore Galli” Theatre in Rimini, a prestigious work for the entire Italian historical, artistic and cultural scenario: opened in 1857 from a project by Luigi Poletti and badly damaged by Allied bombing n 1943, it was returned to the local territory and community on 28 October 2018, exactly 75 years after the last curtain fell. I.T.A.B. played a key role in its restyling by creating the lamellar fir structure that supports the theatre vault and proscenium arch as near to the “soul” of a theatre as one can get. Structural work carried out in full compliance with the architectural standards of the theatre though done with modern equipment and technologies, that without doubt, recreated with precision the atmosphere, style, richness and beauty of the original works. “We were commissioned the structure by the A.C.C - Adriatica Costruzioni Cervese: we produced it with the oikos machining centre and then coated it in flame-proof plywood, completing the work with the finishing touches”.

Fill out the online form to be contacted by a salesperson