gabbiani pt

(512) 931-1962

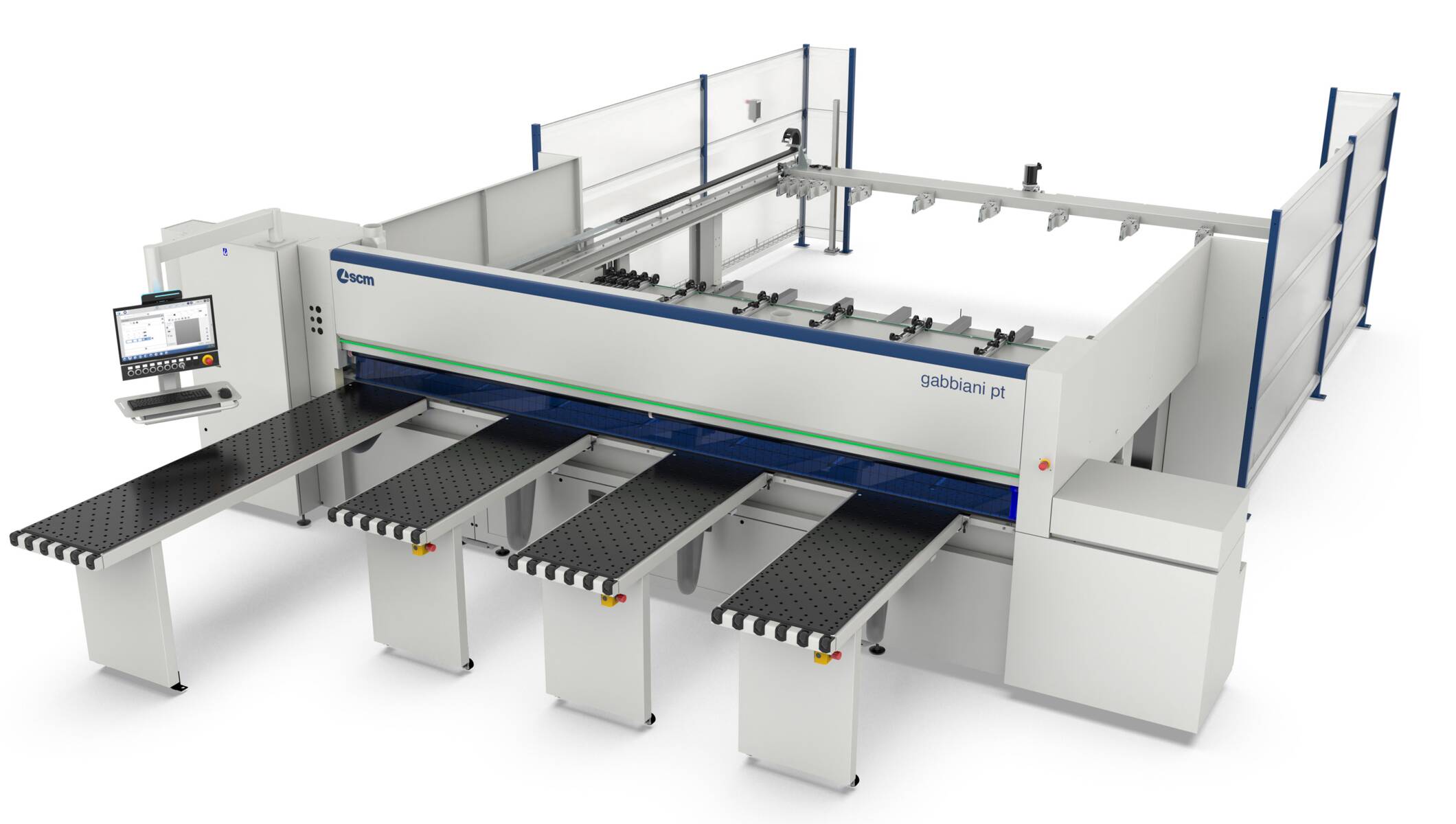

New gabbiani pt is increasingly productive and intuitive and is the ideal automatic horizontal panel saw for the craftsman and small to medium-sized company looking for a streamlined and easy workflow.

These panel saws are intended for cutting panels of wood and its derivatives (chipboard, MDF, plywood, multilayer, fiber).

An intelligent LED bar system guides the user during processing and loading for intuitive and safe production monitoring.

Maximum productivity is ensured by a platform with high loading capacity with any material and format.

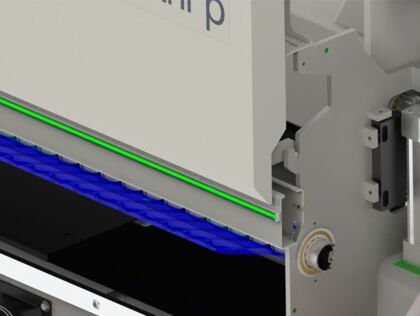

LED BAR: CONTINUOUS ASSISTANCE DURING CUTTING

An intelligent LED bar system guides the user through the processing steps for intuitive and safe production monitoring.

Rear led bar: continuous assistance during stack loading

An intelligent LED bar system guides the user during forklift loading of the stack for proper positioning and signals the need for stack change

FLEXCUT unit: incomparable flexibility and productivity.

Increasing of productivity up to 30% and space saving up to 20% owing to the simultaneous execution of both rip and cross cuts.

| gabbiani | pt80 | pt95 | |

| Cutting lenght | mm | 3300/3800/4300 | |

| Cutting depth on platform | mm | 1850 - 2200 | |

| Max. height of panel stack on platform with support beams | mm | 600 | |

| Blade projection | mm | 80 | 95 |

| Saw carriage variable speed | m/min (opz.) | 0 - 120 | |

| Pusher variable speed | m/min (opz.) | 70 | |

| Main blade motor S6 - 40% | kW (opz.) | 7,5 (9) (11) | |

| Motor power with inverter | kW (opz.) | (11) (15) | (11) (15) (18) |

| Scoring unit blade motor 50 Hz | kW | 1,5 | |

| Main blade 50 Hz | rpm | 4650 | |

| Scorer speed | rpm | 5850 | |

| Main blade diameter | mm | 340 | 370 |

| Scorer blade diameter | mm | 200 | |

| Number of clamps | std | 5 | |

Fill out the online form to be contacted by a salesperson