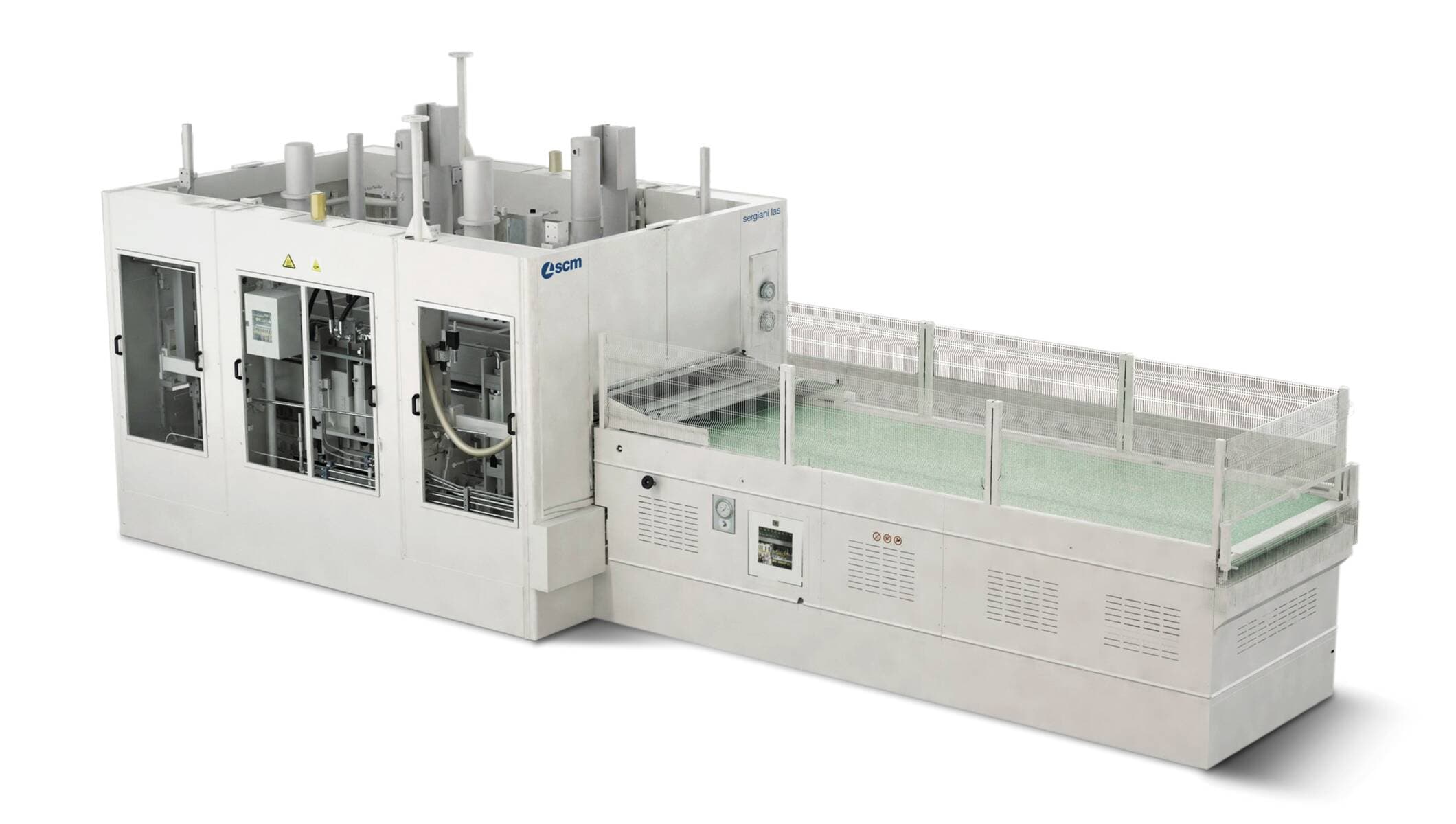

Automatic continuous cycle press (patented) for the production of hollow core and coated (veneer, HPL, CPL) doors and pre-finished parquet (2-3 layers). The press sequentially loads one door at a time, maintaining constant pressure on doors inside other compartments. High productivity press up over 1200 doors per shift.

High productivity:1 door each 20 second

Reduction of loading and unloading downtimes due to the continuous cycle and to fast pressing times by using “rapid glues” both water based and PUR; thus allowing immediate loading of the panel after composition without waiting times.

Better surface and gluing quality compared to a single compartment press with the same productivity, facilitated by the use of one press compartment for each door.

| Model | Platens dimensions (mm) | Number of daylights | Total thrust (ton) |

|---|---|---|---|

| las s | 2500 x 1300 | 5 | 120 |

| las s | 2500 x 1300 | 6 | 120 |

| las s | 2500 x 1300 | 10 | 120 |

| las s | 2800 x 1400 | 5 | 140 |

| las s | 2800 x 1400 | 6 | 140 |

| las s | 2800 x 1400 | 10 | 140 |

| las p | 2500 x 1300 | 5 | 200 |

| las p | 2500 x 1300 | 6 | 200 |

| las p | 2500 x 1300 | 10 | 200 |

| las p | 2800 x 1300 | 5 | 200 |

| las p | 2800 x 1300 | 6 | 200 |

| las p | 2800 x 1300 | 10 | 200 |

| las 3 | 3350 x 1400 | 5 | 175 |

| las 3 | 3350 x 1400 | 7 | 175 |

Fill out the online form to be contacted by a salesperson