FINNMIRROR OY, THE POWER OF “BATCH 1” PRODUCTION

Interview with Rami Suuronen, Head of storage systems product development: “We chose SCM and ‘stefani cell E’ because this new flexible ‘batch 1’ edgebanding solution responds at the best to our present and future needs. Now it is possible for us to produce a more consistent quality”.

With 35 employees and 8 million Euro of turnover, Finnmirror Oy is the largest mirror manufacturer in the Nordic European countries and one of the leading fixture manufacturers in Finland.

Established in 1923, the operation of this family enterprise combines long traditions, modern production technology and environmental consciousness. Their goal is to obtain the highest quality results possible in all production through their almost 100 years of experience, genuine materials and responsible production.

The company’s core business is the manufacture of decorative mirrors and bathroom fixtures but the range of products has expanded in recent years, including the processing of sliding door cabinets, wardrobes and walk in closets with the Inaria brand. All the production is intended mostly for top and medium range customers, a clientele that is highly sensitive to focusing on the design and product. The target market is mostly national but about 10% of the annual turnover includes other countries in Scandinavia, especially Sweden and Norway.

THE NEW MARKET TRENDS

The design manufacturing trends are deeply and rapidly changing and Finnmirror Oy understands this well. It is a clear example of how a company can transform its way of processing to keep up with the ever new needs coming from the market. Finnmirror Oy wanted to be flexible, but at the same time it also needed to be fast, increase its productivity and have total control of the production process. So it started to look for a flexible automation for "batch 1" machining which combined the advantages of customised production with large volumes.

“Consumers demand practical and high quality products and they are free to design the size and fittings”, explains Rami Suuronen, Head of storage systems product development. “This is the reason why our production is ‘batch 1’: orders come from reseller directly to machine”.

SCM’S ANSWER: “STEFANI CELL E”

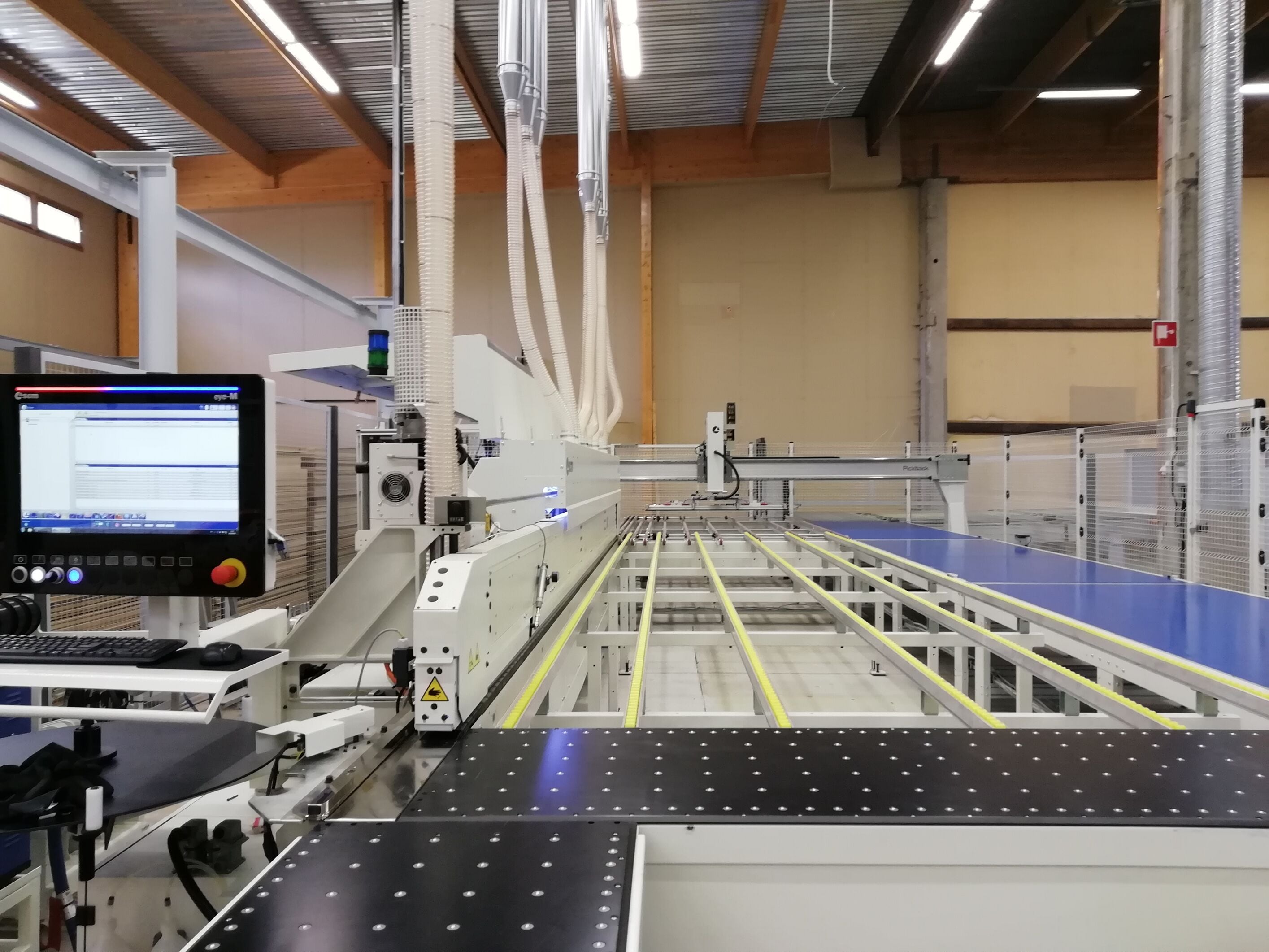

The meeting with the SCM commercial team proved to be decisive. The SCM product area managers, supported by Innomac dealer, have been able to assist the company, fully understand its needs in terms of productivity and business, up to advise the best solutions to its demands. The Finnish company chose to adopt a “stefani cell E”, the new synthesis of "entry level" SCM flexible edge banding cells for "batch 1". Configured with the reloop kit, it consists of a stefani xd single-sided automatic edgebander, designed for industrial production, and the new “Pickback” gantry panel return system.

The use of numerical control high technology allows the company to always accommodate the ever new and diversified production scenarios. All the panel's parameters can be changed easily and quickly (type, colour, edge thickness, position and mortise depth, handling of the protective film, sizes...) while never having to stop the production flow.

The risk of error on the part of the operator is minimal. He has just to launch the program from the Maestro software and the cell automatically adapts to the machining program.

Furthermore the new "Pickback" gantry panel return system guarantees a simple, “just in time” production management. This way, the operator can focus solely on feeding the panels back into the edgebander, as simply and ergonomically as possible.

“Advanced machines and automation are very important to improve productivity and we expect that in the future this point strength will become more and more decisive in satisfying market demands” comments Mr Suuronen. “We chose SCM and ‘stefani cell E’ because this new flexible ‘batch 1’ edgebanding solution responds at the best to our present and future needs. Now it is possible for us to produce a more consistent quality”.

Another technical feature that is most appreciated by this client is that all units are controlled by servo motors with a high level of automation also in the edge finishing stage. “This system allows us a more flexible batch one production”.

AN ALL-ROUND SUPPORT AND ADVICE

Thanks to the “stefani cell” edge banding solution Finnmirror Oy has been able to increase its productivity up to reach the target of 450 “batch 1” panels processed per shift. “And there’s still extensive room for improvement” state Davide Fracca and Francesco Bottini, SCM Product Area Managers.

SCM has been chosen with respect to its competitors, including those that already had commercial relations with the client, for the reliability of the brand, the technological level of the new flexible industrial edge banding cell, but above all for the ability of SCM and Innomac professionals to listen to the customer, to meet its needs, to respond quickly to its requests both in the pre- and post-sales phases.

An all-round support and advice from both the commercial and service team, which well reflects the “SCM approach": always being at the side of the woodworking companies. "The owners of Finnmirror were very happy with the installation, testing and support provided by our technicians, who have done a really good job", says Fracca and Bottini.

The relationship with the customer is as important as the technology, and sometimes it can really make the difference.

Fill out the online form to be contacted by a salesperson