MéO is a company within the family group Vendée LIEBOT with 12 companies and with more than 3,600 employees in France and Europe. MéO’s mission has always been to offer the most complete range of wood-aluminium windows and doors on the market: windows and French windows with frame, sliding glass doors, front doors, shaped fixtures, glass roofs and porches. Its plant in Cugand is one of the most modern production units in Europe. The company uses high performance industrial machines to meet the market’s very high technical demands with a global approach, close attention to the sustainability of materials and internal processes and a specialist team to design and satisfy the most complex requests. A business where artisan know-how and top-quality industrial performance blend together perfectly.

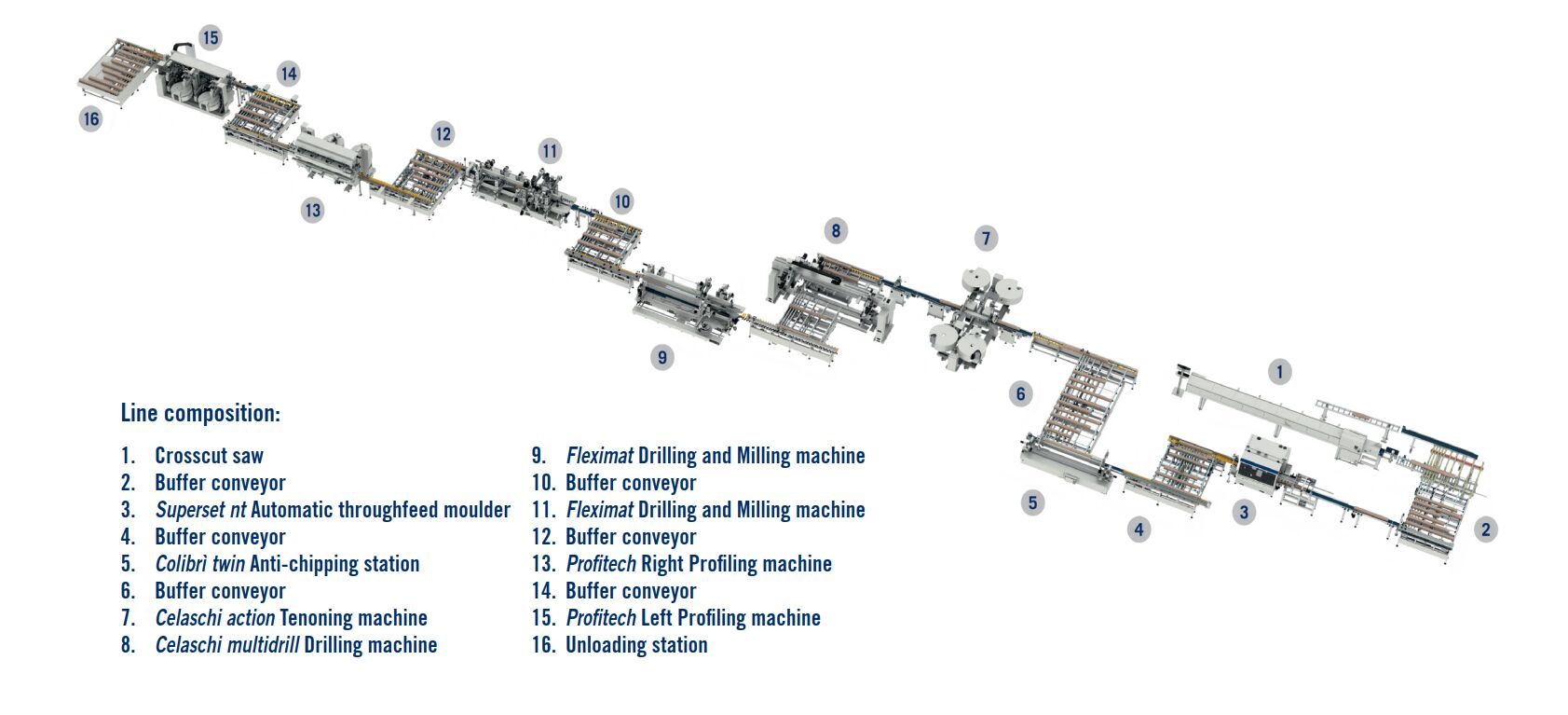

Their investments with SCM are clear to see. In 2012, MéO purchased a “system 8” integrated line which led to excellent results in terms of production volumes. In 2021, it chose a second new high-automation line, the “system 9”, to increase production volumes by a further 60% as of 2025. This new SCM line stands out for the rapidity in its setup change and the extreme flexibility in the management of work-pieces with different dimensions, allowing the manufacturing of up to 200 complete windows per working shift, even with medium-small batches.

As with all the SCM “systems”, the integration of multiple machines enables to perform all the operations for producing windows frame: planing with the “superset nt” throughfeed moulder, tenoning with the new “celaschi action”, drilling and routing with the “fleximat” machining centre and profiling on both right and left sides with two “profitech” machines. The new “celaschi action” double-sided tenoning machine, the beating heart of the “system 9” line, allows simultaneous tenoning of two elements of different lengths, widths and thicknesses, exploiting the principle of machining with the motors moving when the pieces are stationary. Among the plus points is a high degree of flexibility in the production of tenons, thanks to the presence of 4 electrospindles, each of which is served by a 6-position tool changer. It is thus possible to produce from 30 to 48 different tenons without any intervention by the operator.

This integrated line stands out with a productivity of up to 6 pieces a minute and it can manage pieces with length from 350 to 3100 mm, width from 35 to 130 mm and thickness from 35 to 100 mm. It is also fully in line with the demands for a digital, connected and integrated production. The HMI Maestro active watch software manages the entire system and was designed to be easy to use and to import orders directly from the company management software. Thanks to Maestro active, the unified operator interface for all of SCM’s technological solutions, the operator can control different machines very easily, with the great advantage of a unique, attractive and user-friendly look&feel.

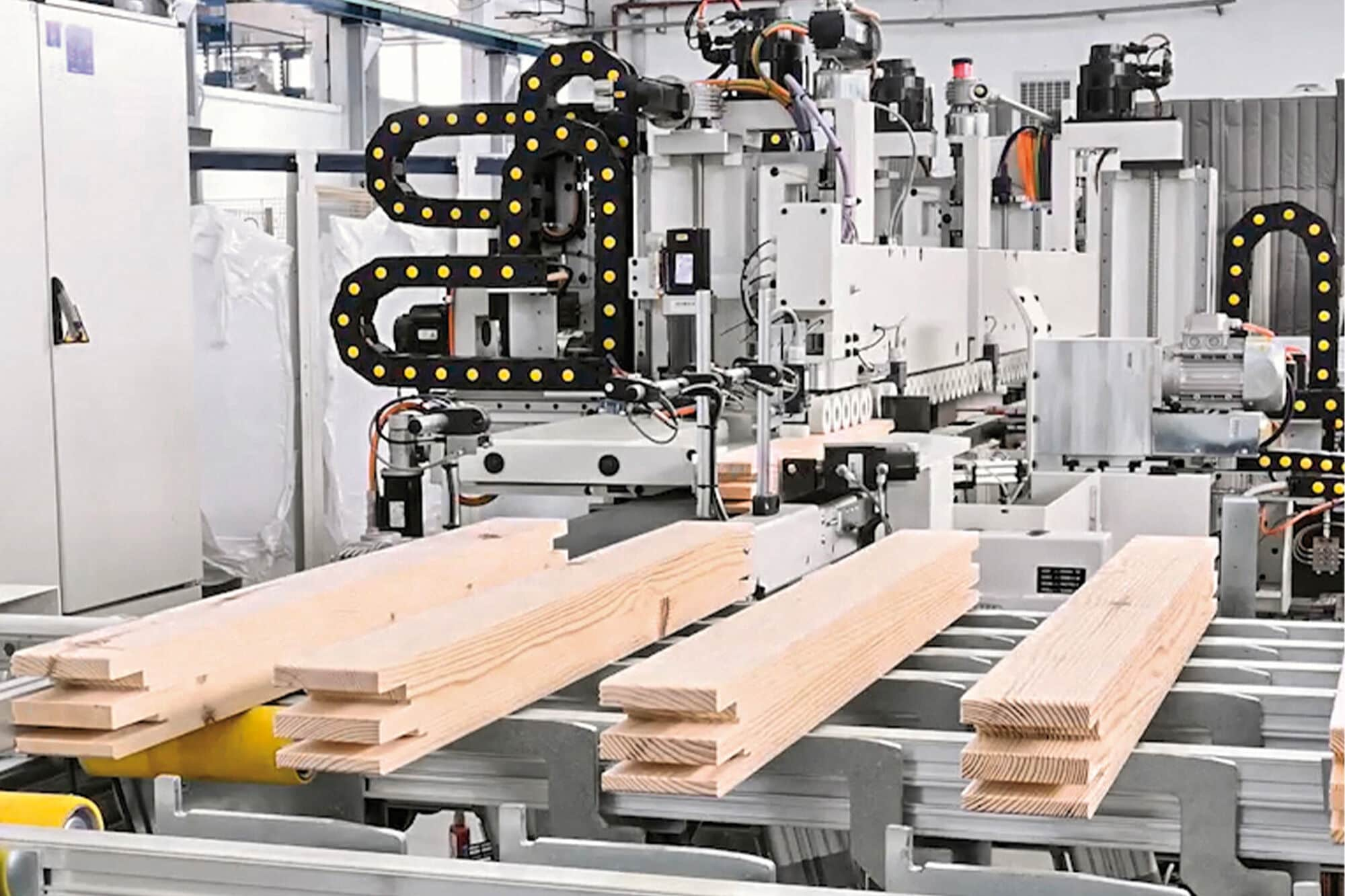

Another SCM solution used by MéO is windorflex, automatic machining cell for the complete production of windows and doors which optimises production rhythms by maintaining high flexibility and excellent finishing. In more specific terms, the version found at the MéO plant has a double automatic worktable, each one with dedicated clamps for the constant holding of the work-pieces. It is possible to process from 1 to 4 work-pieces in sequence. The worktable modularity allows managing three work-piece lengths: 3500, 4500, 6000 mm. The work-piece repositioning, from the internal side machining to the external one, is direct between the clamps, without needing additional devices, to ensure excellent finish quality.

Another advantage is the automatic work-pieces loading/unloading system that enables the machine to work autonomously, without the continuous input of the operator: an anthropomorphous robot picks up the rough elements and unloads the finished work-pieces on special trolleys. Thanks to windorflex and its Maestro active windoor control and programming software, nowadays, MéO can handle any request for windows and doors production.

The French manufacturer’s travels into the future continue by always guaranteeing their clients’ comfort through high technology.

“This investment will allow us to double our woodworking capacity and thus accompany the company's growth for the next few years,

improving the quality of production and productivity”

Franck Rostand, General Manager of MéO

Fill out the online form to be contacted by a salesperson