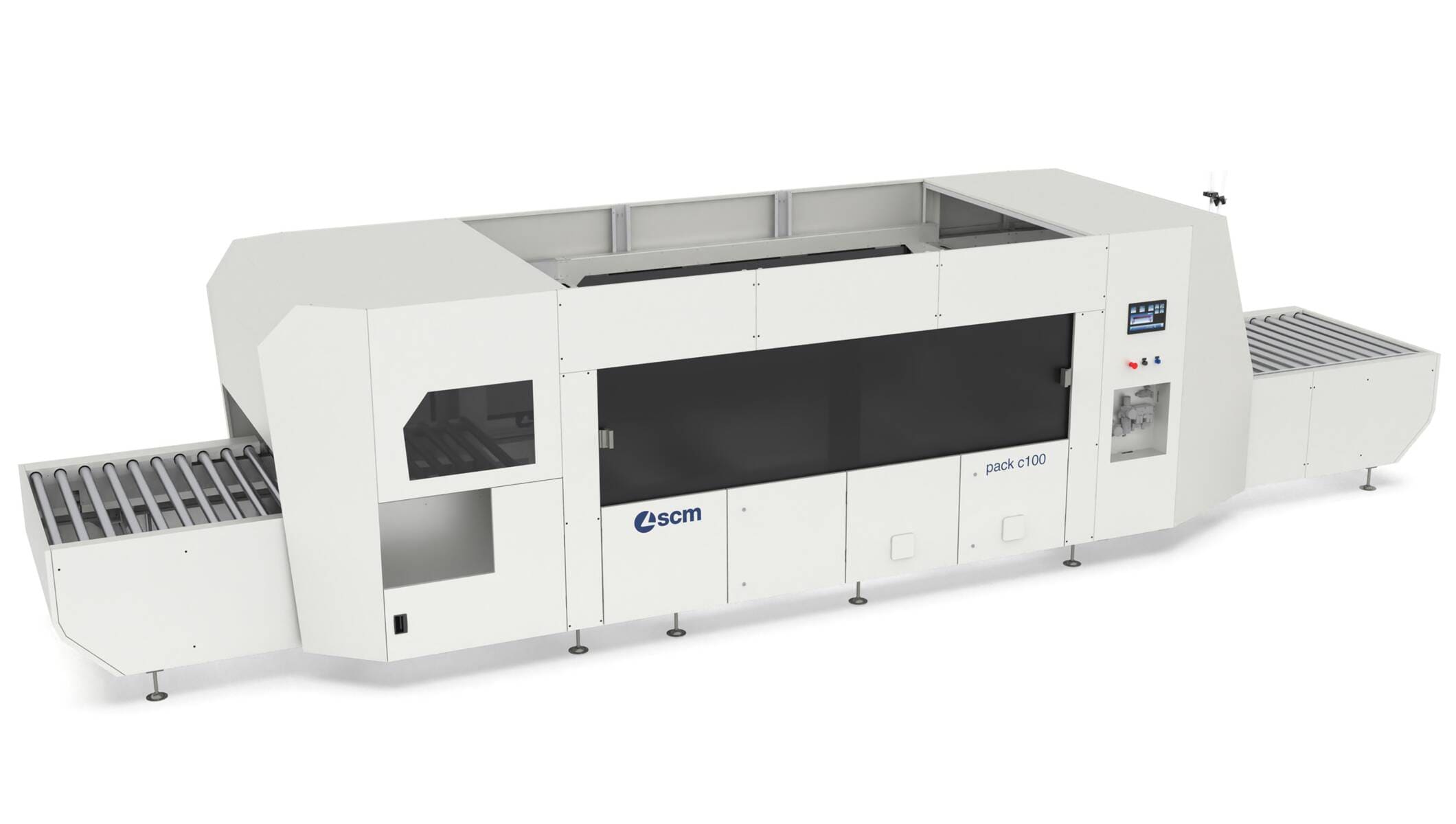

Pack c 100 is the solution for automatically closing the lid of a die-cut cardboard box (FEFCO code 410) with hot-melt glue. The product is manually inserted inside the pre-shaped box and fed into the machine. Thanks to the automatic detection of the carton size, it is possible to make packages with boxes of different sizes, placed sequentially at the infeed. The solution is ideal for kit furniture manufacturers.

HOT MELT is the technology for the closing of the boxes which ensures high quality packaging standards constant over time.

AUTOMATIC READING OF THE BOX DIMENSIONS, to adapt the process to the production requirements, starting from the large-scale to the small dimension batches down to the batch 1 manufacturing.

|

|

|

pack c 100 |

|

Max. productivity (batch production*) |

No. |

8 |

|

Min. box length (external sizes) |

mm |

350 |

|

Max. box length (external sizes) |

mm |

2500 |

|

Min. box height (external sizes) |

mm |

35 |

|

Max. box height (external sizes) |

mm |

250 |

|

Min. box depth |

mm |

250 |

|

Max. box depth |

mm |

1200 |

Fill out the online form to be contacted by a salesperson