But what’s behind a simple drawer? More than you might think—a real business opportunity! The Italian company, based in the province of Venice, has carved out a niche by focusing exclusively on bedroom storage furniture for the U.S. market. Unlike companies that prioritize wardrobes, Imar’s expertise lies in manufacturing bedside tables, dressers, and chests of drawers. With a monthly output of around 7,000 furnished rooms, this translates to an impressive 80,000 drawers produced every month.

The production manager, Fabio Zoia, explains: “Up until recently, 100% of the drawers were purchased from various suppliers, but as it is a key component for the final assembly at our production site in North Carolina in the USA, it became strategic for us to control the entire production supply chain. This is why we decided to start producing them internally and, in addition, with a kind of processing that brought with it numerous advantages compared to the traditional one”.

We are talking about the folding process where the drawer edge is obtained from a single, semi-finished piece, rather than three traditional elements. This greatly benefits production-line assembly. “The concept of the piece of furniture in a kit is not something we currently do because our end client wants the piece of furniture already assembled - explains Zoia -. We chose to produce drawers in folding because, to this day, it is still the fastest system for this kind of artefact: all it takes is a single piece and some glue to have a drawer ready for use”.

Covid, when the drawers were still being bought from third parties, was yet another decisive incentive. “We have 47,000 covered square metres, 40% of which set aside as a warehouse, but despite everything, we found ourselves with rooms that couldn’t be assembled because the drawers were missing. At that point - continues Zoia - the choice was clear: make them internally and become 100% self-sufficient with the contents of the piece of furniture”.

The turning point

When it came time for Imar to take the big leap forward, the company sought a technological solution that would provide greater vertical integration, enhanced production flexibility, and improved product quality – all while maintaining high efficiency. The challenge? Drawers for the American market require customization and precise design, making it difficult to balance flexibility with mass production efficiency.

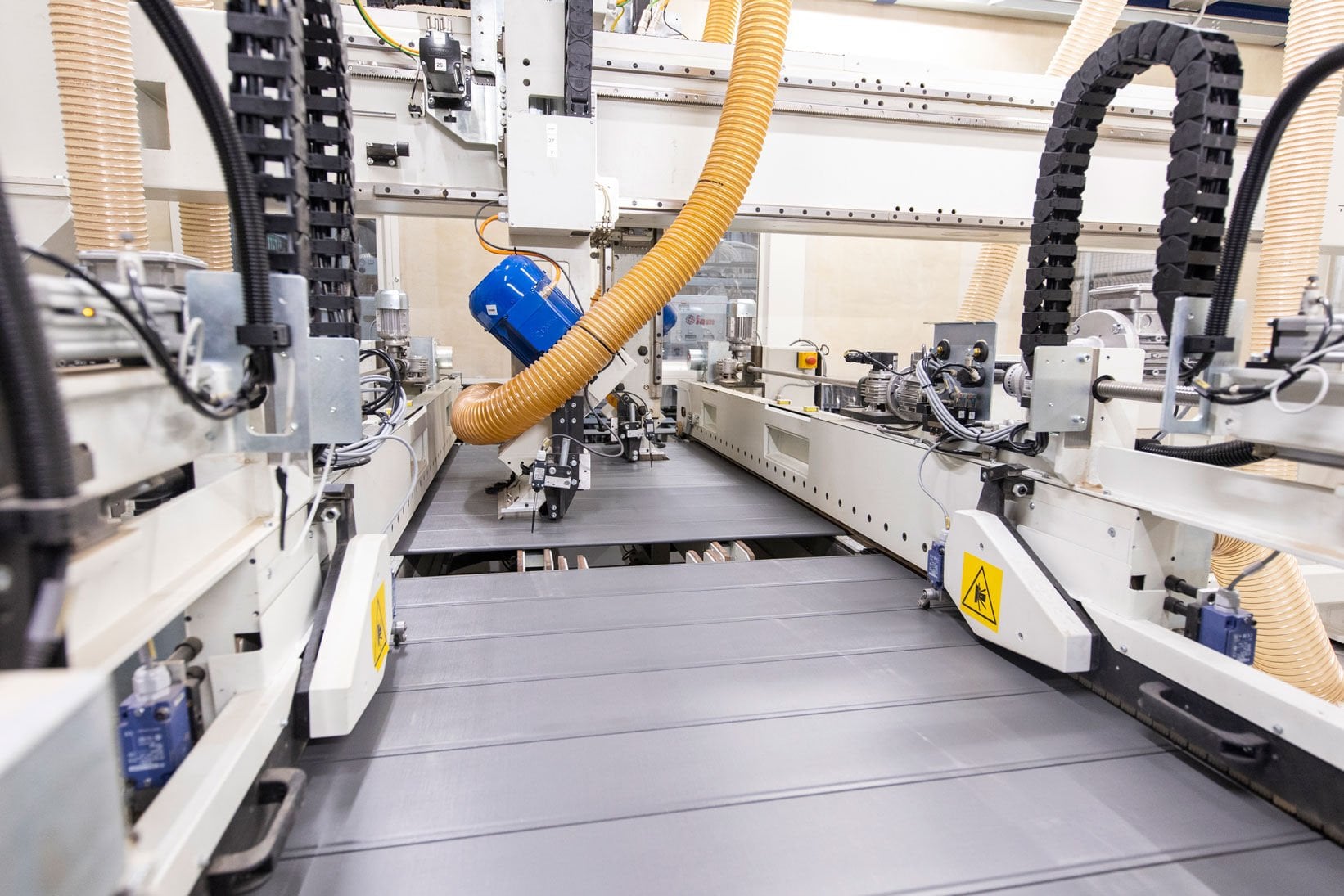

SCM and its Engineering team stepped in with a cutting-edge solution: a high-productivity squaring, drilling and dowelling line, consisting of a robotic loading station, a “celaschi sp” squaring machine, a drilling-dowelling machine, a connecting and transversal tipping station and another robotic unloading area. A Maestro active watch supervisor software provides central control over machines, automation systems, material flow, production monitoring, emergency reports, diagnostics and integration with the factory’s administrative system.

How does it work? The drawer sides arrive at the production line pre-machined from other processing stations. In the Celaschi SP, pieces are automatically loaded, squared, and trimmed. Then, central V-grooves are precisely cut to allow the panels to fold, with only a few tenths of a millimeter of coating remaining intact. Next, the drilling machine creates holes for track assembly, head joints, and dowels to attach the front panel.

One of the most innovative features of this line is the lifting and tipping system, which ensures seamless transfer to the unloading robot. Thanks to roto-transfer extractor hoods, only the required pieces are picked up, rotated, and placed onto pallets—eliminating the risk of damage during movement.

“Thanks to this new system we manage to apply economies of scale, increasing the volumes and optimising costs. We are more efficient because we have enhanced the coating department, by managing to work two shifts. We can also achieve greater customisation on our products: now we can manufacture drawers with bespoke decorations, instead of limiting ourselves to the classic colours of grey, white and black. A change which allows us to be faster, more competitive and ready to meet market demands”.

Fabio Zoia, Production Manager of Imar

Fill out the online form to be contacted by a salesperson