In the thriving centre of the Italian nautical industry in La Spezia, we find New Team, a company that has made flexibility and attention to detail its mantra. Founded in 2004 as a small family-run joinery workshop, nowadays New Team can boast 150 employees across Europe and a turnover in excess of 7 million Euro, surfing across oceans and continents with its quality furnishings.

At the helm of New Team, a genuine fleet of talent, we find Mauro De Vita, an industry magnate who has managed to steer the company from the calm waters of the local market out into the tempestuous waves of the global landscape. His strategic vision and in-depth knowledge of the industry has allowed New Team to become a reliable partner for the most prestigious Italian and foreign naval boatyards, the most important names in Italy to foreign partners located in Germany and the Netherlands.

A close-knit and versatile crew

The beating heart of New Team is its team of 150 people, a close-knit and highly qualified group that works in harmony to produce top-quality products. Expert joiners, creative engineers and visionary designers work alongside one another to bring life to pieces of furniture, cladding and furnishing accessories which stand out for their elegance, practicality and attention to detail. The increasingly expert exchange of specialists comes from local universities (Faculty of Architecture in Genoa and the Faculty of Naval Engineering, nautical course, Nautical Engineering, both in La Spezia) with whom New Team has established excellent partnerships where they can welcome and nurture young professionals in the industry, from designers to architects.

A sea of opportunities

New Team does not just navigate the seas of the nautical industry. The company also provides services to the civil construction industry, producing bespoke furnishing for hotels, restaurants and luxury villas. The flexibility and ability to customise each project based around the client’s needs are the strong points which allow New Team to stand apart from the competition even in the hotel and civil construction sector.

Technology at the service of craftsmanship

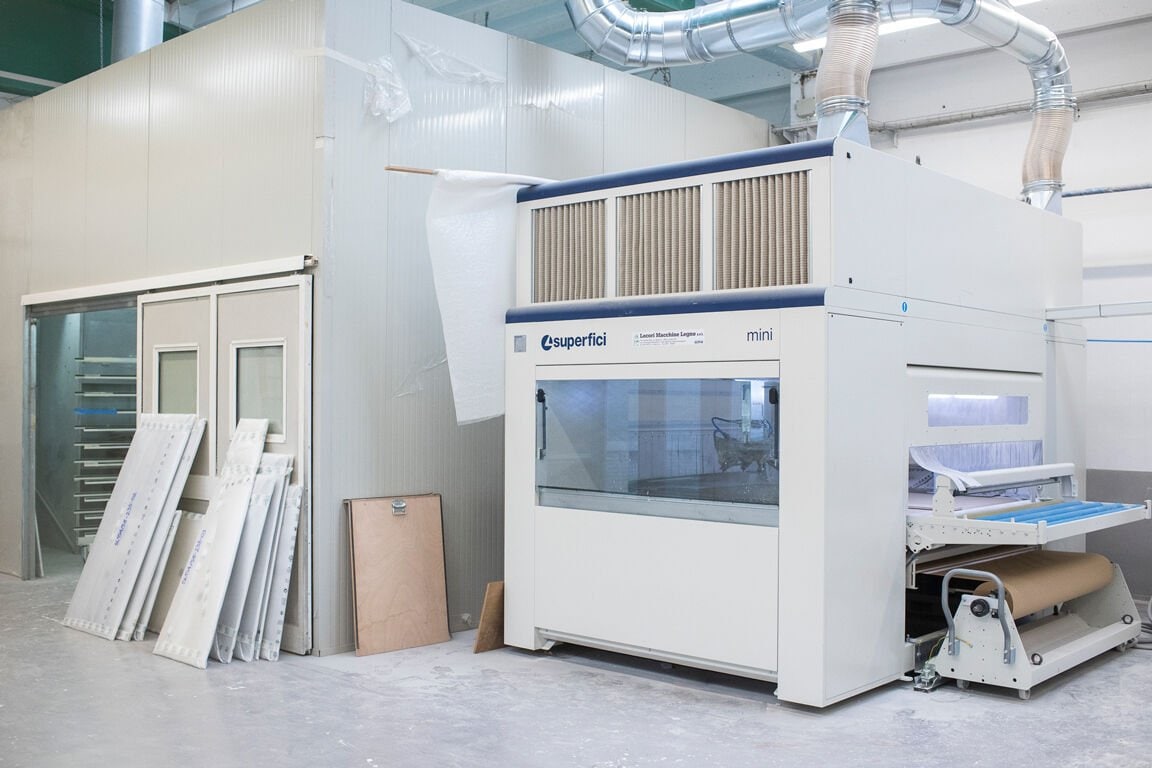

New Team has no fear of setting sail towards new horizons and embracing technological innovations. The company recently invested in 4.0 technologies with the Superfici “mini plus p”, sprayer, as well as boasting an already complete range of machines all of them provided by Scm Group like the “morbidelli m100” and “morbidelli x200” CNC machining centres, two “olimpic k560” edgebanders, a “dmc” sanding machine and a variety of traditional machines. These new technological solutions have allowed them to increase productivity, precision and the quality of products, while simultaneously guaranteeing an efficient, sustainable production process. Production was aided by the move to an ever more driven automation.

A key example was the recent purchase of a “mini plus p” from Superfici. The market offered painting machines mainly specialised in other sectors, like car bodywork, that were only moderately and sufficiently suited for to machining wood. This led to a number of critical issues including: difficulty painting edges, a waste of paint and failure to replicate the process. The introduction of Superfici’s “mini plus p”’ sprayer coater was a game changer for New Team, solving all the critical issues that the company had encountered but which, to a certain extent, are common to those working with manual sprayers. The advantages which now elevate New Team’s production to a higher level are:

In addition to these benefits, the Superfici “mini plus p” also brought about advantages such as improved safety for workers, reducing the exposure of workers to paint vapours and reducing operator fatigue, by easing the workload and increasing productivity.

Investing in the Superfici spray machine proved, therefore, to be a success for New Team, contributing to better quality, efficiency and production process safety. The machine allowed the company to achieve new standards in quality and position itself as leader in the naval and civil furnishing sector.

A radiant future on the horizon

New Team looks to the future with optimism and ambition. The company is ready to take on new challenges and conquer new markets, always faithful to its founding values: the passion for craftsmanship, attention to detail and a focus on the client’s needs.

A captivating journey through tradition and innovation

The story of New Team is a captivating journey through tradition and innovation, an example of how Italian craftsmanship can evolve and adapt to new market demands. A company who made flexibility and quality its creed, becoming a benchmark in the naval and civil construction furnishing sector.

Fill out the online form to be contacted by a salesperson