Founded in 1960 in Vandea by Patrice and Annick Gautier, the French company Gautier quickly expanded to become a leader in children’s furnishings. The creativity and high quality of their furnishings have always been Gautier’s strong point, at the heart of their growth and evolution over time. In the 1980s, the company created an innovative concept in the furniture sector: a bedroom as a personal living space for children. With the same inventiveness and audaciousness, Gautier later launched into the creation of adult bedroom furniture and the production of office furniture. The end of the 1990s saw the launch of the first collection of living-room furniture and in the early 2000s, furniture for dressing rooms with bespoke collections which clients loved even more. In 2005, Gautier reinvented its distribution circuit and launched the first franchising shop. This was followed by about another hundred in France and abroad (Belgium, Saudi Arabia, India, Bulgaria, Morocco, Martinique, Guadalupe, Réunion Island and New Caledonia...).

The company has always moved with the times and keeps a close eye on market demands and environmental issues. In 2006, it launched into designing ecological products with wood from sustainably run local forests or with recycled forest wood. In 2007, Gautier became the first manufacturer of French furniture to be awarded the triple certification ISO 9001, ISO 14001 and OHSAS 18001, with regard to quality, the environment and safety in the workplace. Led by David Soulard, CEO, nowadays, Gautier has around 700 employees with three production plants all in Vandea, and boasts over 70 shops in France. Exports represent 20% of their current turnover.

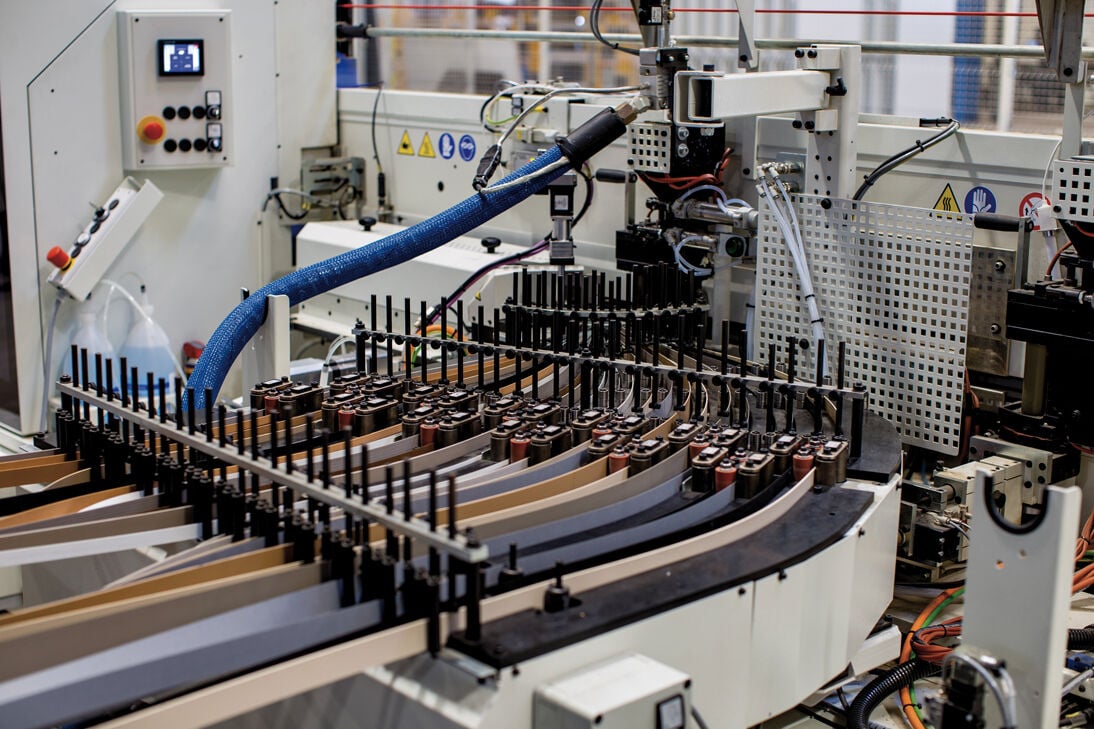

Another equally important factor in this Made in France success story has been the innovation of its production processes. In 2015, Gautier expanded its industrial site by investing heavily in the plant at Le Boupère, mainly for the new FLEX machining line. Most of this investment, spreading across 1,500 m2 of production surface, was manufactured by SCM for the purchase of a line with two drilling machines and a morbidelli cnc machining centre, a mahros moving system and a customised software supervision system to handle and produce the production lists, as well as monitor the flow of different products on the line in real time.

The main requirements were production flexibility, a chance to create complex projects, improve the level of quality, reduce the duration of the manufacturing cycles, achieve higher production capacity, keep working conditions in mind, make energy savings and lastly, reduce the size of the batches and manufacturing time of the pieces.

More recently, Gautier opted for another ambitious project for its third plant in Saint-Prouan: a fully integrated, high-automation line for “batch-one” machining. This is one of SCM’s most advanced engineering projects, a line extending 100 metres and entirely produced by the Italian group to meet Gautier’s growing demands - and those of the furniture industry in general - for solutions capable of producing furniture with plenty of flexibility and a low impact on the workforce. These advantages are accompanied by high machining quality and precision, an optimisation of materials and the reduction of intermediate magazines. This line includes a storage and nesting area with two flexstore hp automatic magazines, an ergon nt cnc nesting machining centre and a robot that picks up machined pieces and places them on a moving roller unit as far as a mahros station to then connect with the next edgebanding cell. This second plant sees a stefani one single-sided edgebander in action aided by two mahros automatic loading and unloading stations. Another connection station conveys the edgebanded pieces to the next drilling area, with two morbidelli ux200 cnc drilling centres with automatic unloading. Further downstream, we find a sorting and outfeed area with a storage cell with vertical magazine, where the panels are sorted in fully automatic mode by another two industrial robots. What is also key on this line is the supply of software with supervisors and software for the optimisation and tracking in real time of the entire process.

That’s not all, because at the same factory, Gautier chose to equip it with two independent machining areas: a morbidelli p200 cnc machining centre for drilling, routing and edgebanding; the other with a class si 400 circular saw.

“This investment will allow us to manufacture fully bespoke products in the home furnishings and contract sectors, to meet the expectations of clients looking to choose their optional extras and finishings”

- David Soulard, CEO of Gautier

Fill out the online form to be contacted by a salesperson