What is there beyond top of the range?

Feb 29, 2024Often, when you want to achieve the highest possible productivity, you focus on owning the highest performing machine. Owning a top-of-the-range machine is an important step toward excellence, but productivity is also affected by factors unrelated to the machine.

One of the main external factors to consider is the percentage of unproductive time compared to the total production time for a workpiece.

This "waste" can arise from several factors:

- Manual worktable set-up on the machine

· Dead time while loading and unloading workpieces

- Manually cleaning the machine at the end of fabrication.

Although they may seem negligible when taken individually, they add up, greatly reducing overall efficiency.

But how can I reduce unproductive time? CMS has designed several specific solutions to minimize this waste:

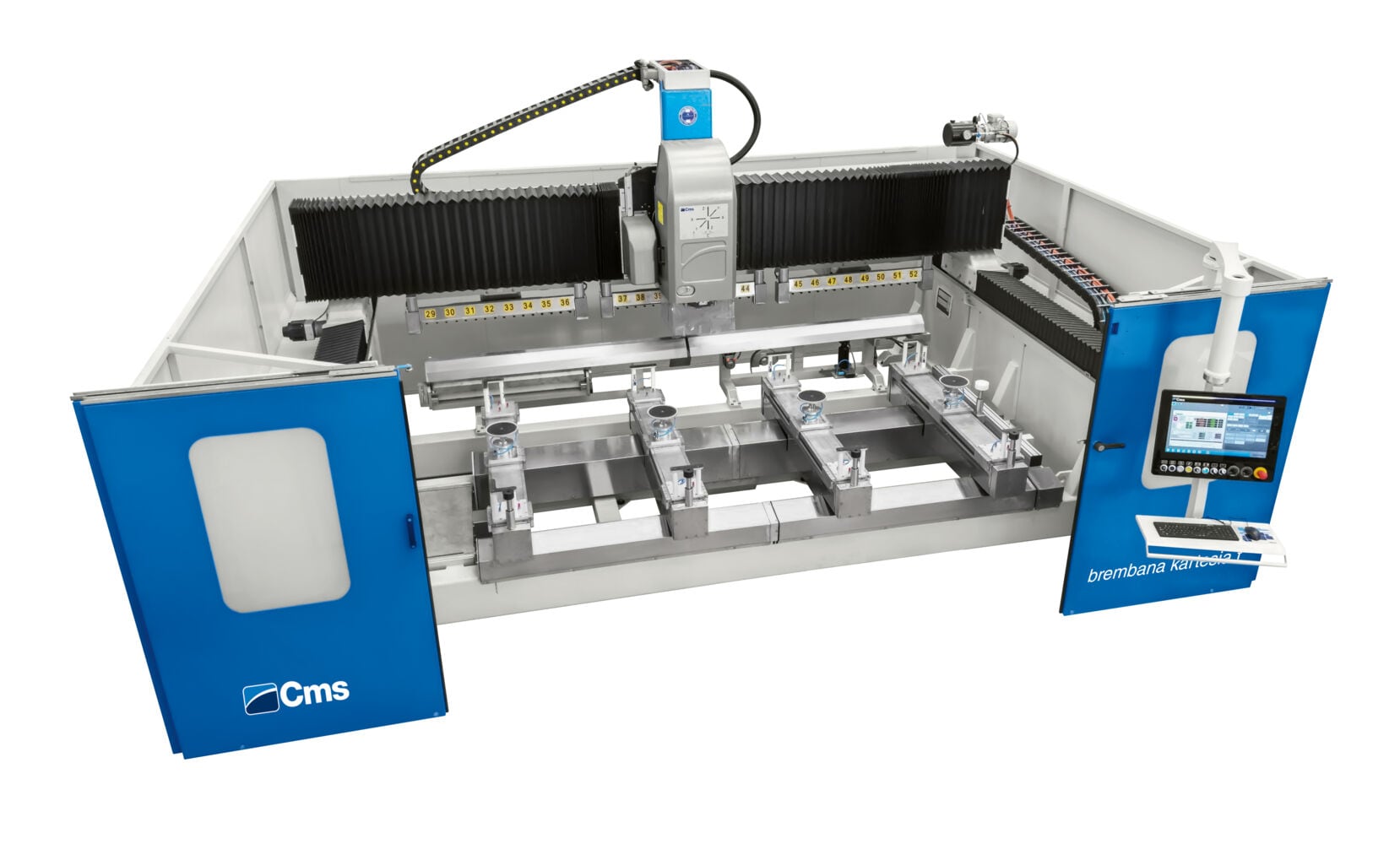

- The brembana kartesia machining center features automatic worktable set-up.

- The speed tr machining center with rotary worktable allows worktable set-up to be done in masked time.

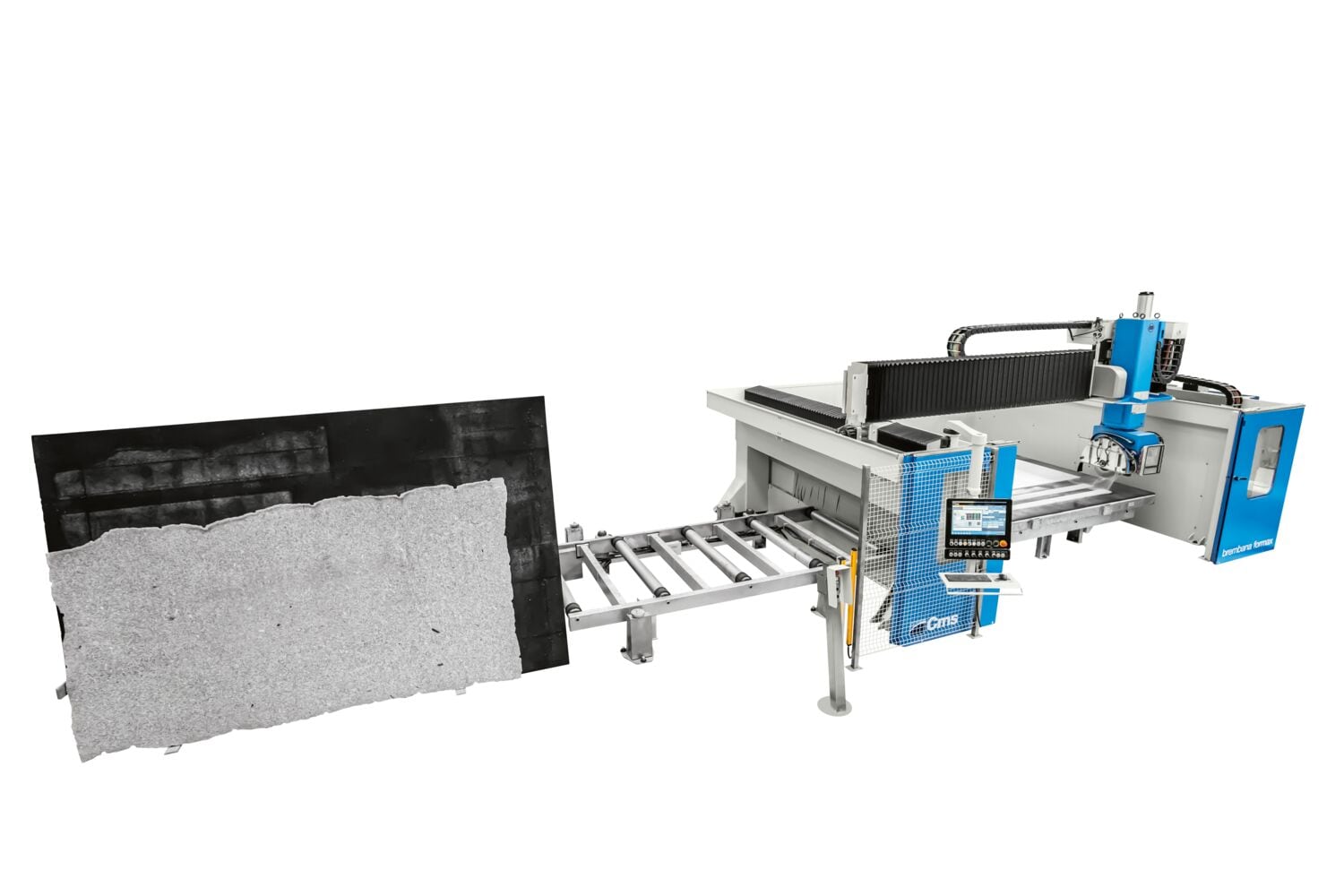

- Bridge Saws with pallet change (dual) allow loading, unloading and work environment cleaning to be done in masked time.

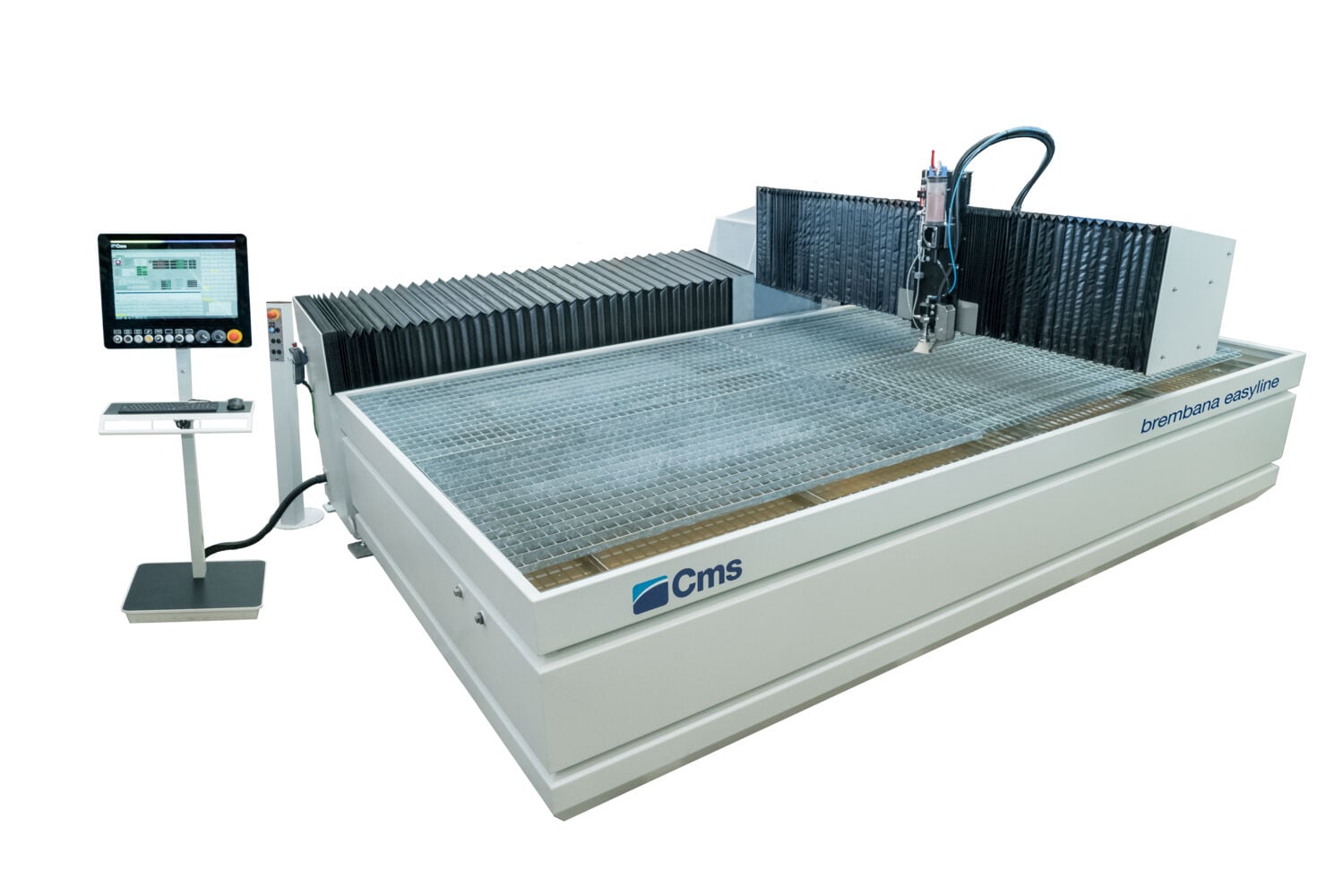

- Waterjet cutting machines equipped with a dredge to automatically remove the used abrasive minimize unproductive time due to this periodic need typical of waterjet technology.

With CMS solutions, operators can focus on high-value activities, while minimizing unproductive time and maximizing overall production efficiency.

Every minute saved directly translates into a competitive advantage on the market.

Contact us and together we can find the right solution for you!