Factory control made easy

With Maestro easyFLOW you can...

Plug & Play

Maestro easyFLOW is the first MES software developed for the manufacturing industry that can be installed in a few easy steps.

Choose the SCM machine to be interconnected to Maestro easyFLOW, key in the machine's network address and you're done: your office and your factory are interconnected!

DATA

1.1 SCM machine configuration wizard controlled by Maestro easyFLOW

1.2 Data Import: Job order import

SCHEDULE

2.1 Creation of job orders (Production order management)

2.2 Useful layouts for production management:

- Job orders with delivery dates

- Production orders with work distribution across the machines

2.3 Sending of programs to the machines (Industry 4.0 interconnection

CONTROL

3.1 Feedback from the MES machines (Industry 4.0 interconnection)

3.2 Production progress check (Monitoring progress)

ANALYSIS

4.1 Order progress report

4.2 Order productivity report

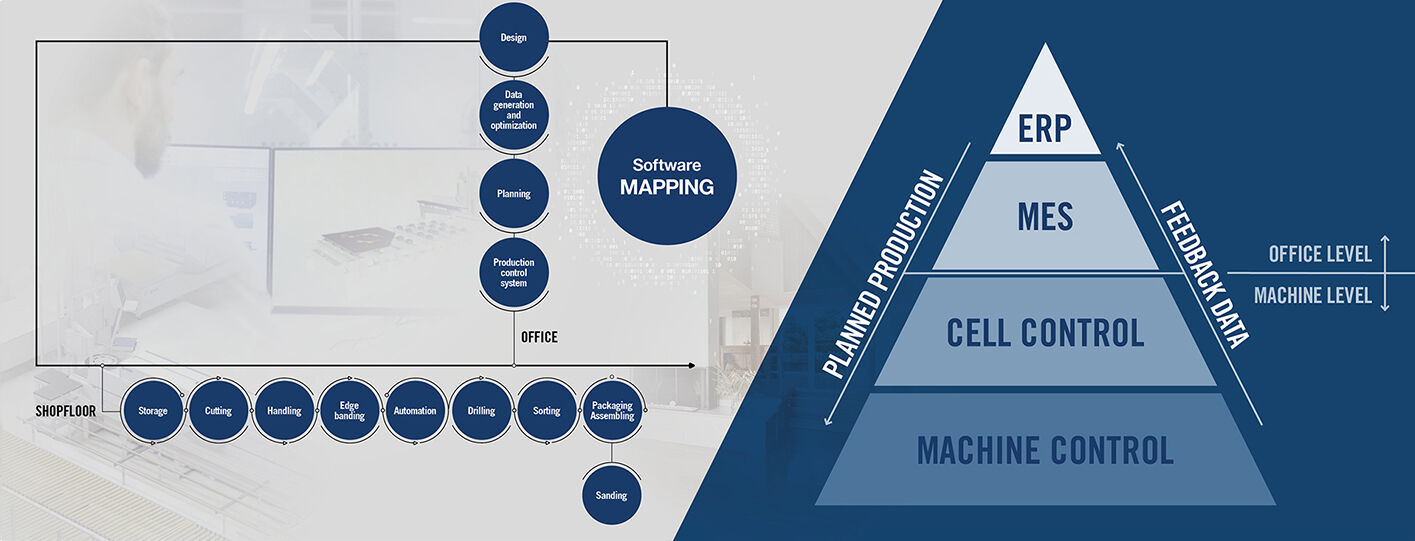

Data integration

An all-round integrated software system: Maestro easyFLOW allows you to connect your design software, SCM cutting optimisers and the machine software, thus creating a real 4.0 vertical integration.

The key to Industry 4.0: it has never been easier with Maestro easyFLOW!

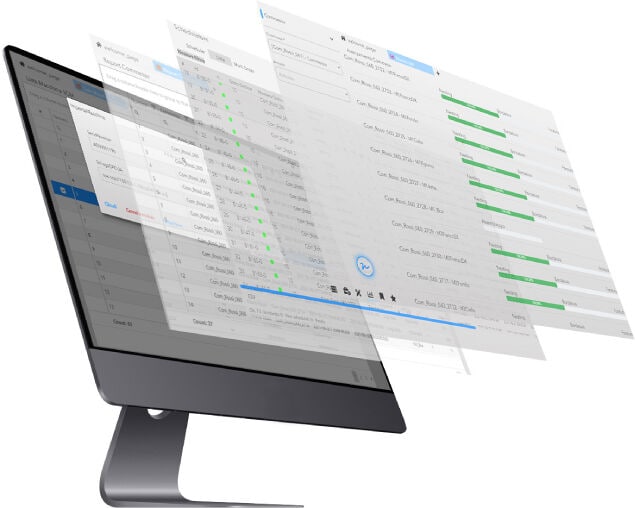

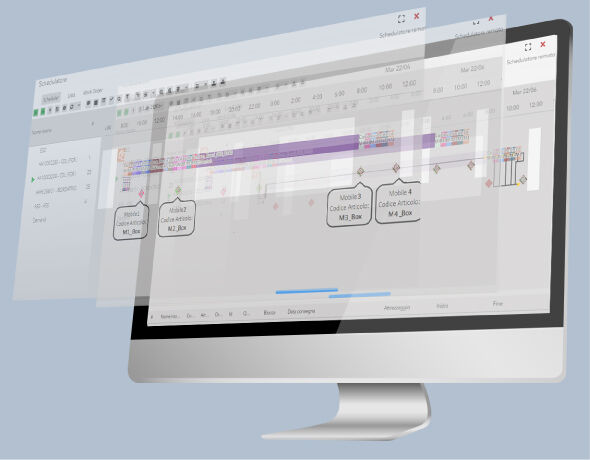

Schedule

"Can I deliver my order on time?" Thanks to Maestro easyFLOW' scheduler, from now on you will always have the answer to this question

The Meastro easyFLOW scheduler takes the job order with all its production items in input, and depending on machine availability and delivery date, distributes the work to your machines. It allows to organise and plan the production and it shows if you can deliver the order or not within the time scale requested by the Customer.

Control

"What stage of completion is my order at?" With Maestro easyFLOW you know the status of your work order in the factory.

Check production progress and track the different work orders! For example: "Is the right side panel currently on the CX200 drilling machine? Are you on schedule with the production planning? With Maestro easyFLOW, finally you will have full control over the management of your production!

Analysis

"What did I produce today, did I accumulate backlogs with my deliveries and if yes, why?"

At the end of the day, check the completion or progress of your job order, if you are on schedule with deliveries or if you foresee delays, so that you can guarantee maximum customer satisfaction!

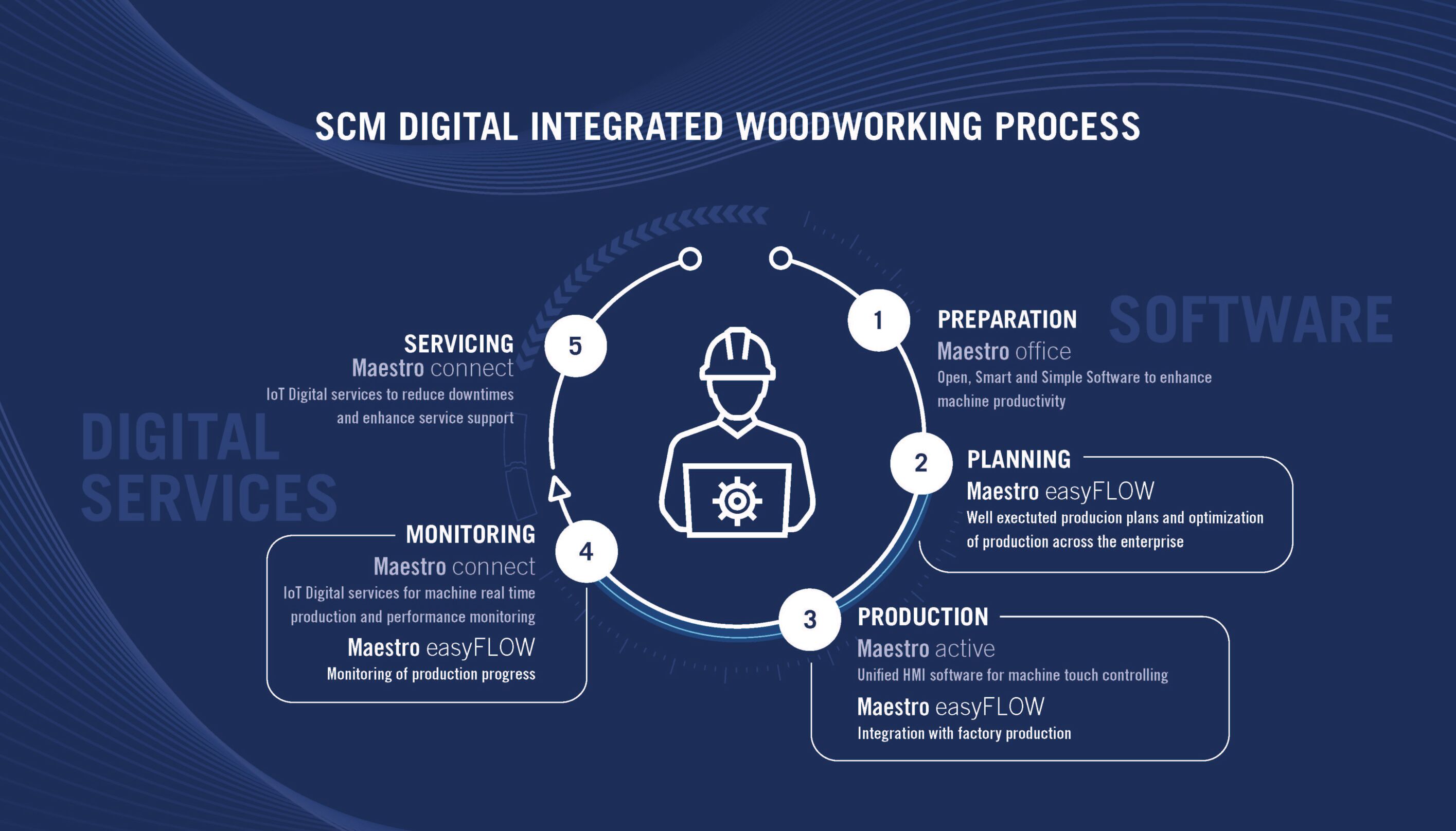

The key role of the MES

The MES (Manufacturing Execution System) is a factory information system that manages and control the whole production process, from the order release to the finished product, with the aim of achieving the production excellence.

Ideally, it is placed between ERP and the software for the cell or Machine Controls (including HMI) and it manages the production process in an integrated and efficient way, with the aim of filling the gap between the management and the execution level, by communicating with all the productive resources: operators, machines/equipment/lines, tools and the whole automation level of the production process.

Industry 4.0 represents the future. Manufacturing companies should invest in MES projects to become:

MORE EFFICIENT

MORE EFFICIENT

MORE ORGANIZED

MORE ORGANIZED

MORE PRODUCTIVE

MORE PRODUCTIVE

MORE COMPETITIVE

MORE COMPETITIVE

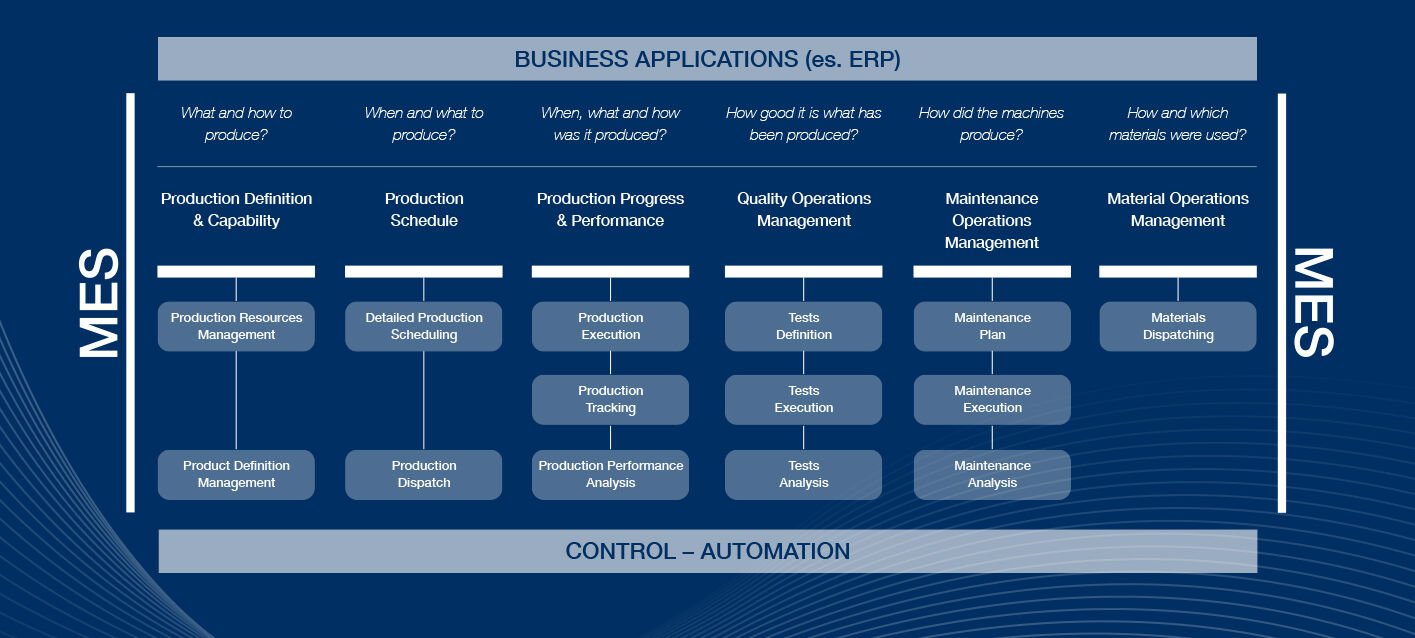

MES functionalities

MES Benefits

A well-run production plant can bring many benefits in a short time, with the sole implementation of a MES combined with performance measurement:

Job production Scheduling

Off-cuts reduction

Reduction in waste

Missing piece reduction