The collaboration between SCM and Marlegno, benchmark in the eco timber construction industry, goes way beyond the purchase of the innovative 6-axis cnc machining centre “oikos x”. It is a journey that is taking us to new, unthinkable destinations in the construction of state-of-the-art, eco-sustainable homes, where the digitalisation of processes and predictive maintenance of technologies play a key role.

More than twenty years of technological innovation in eco timber construction, with eco-sustainable homes focusing both on people's well-being and respect for the environment. Over and above being a business specialising in the design, manufacture and installation of "green" buildings, Marlegno is an all-round welfare project that, in its many facets, makes the quality of life and living a genuine vocation.

This becomes clear as soon as you enter its headquarters in Bolgare, in the province of Bergamo, which is vast, welcoming and bright, with various hints of wood and warmth that only this kind of material can give you. Confirmation comes from the projects that this business creates: whether we are talking about individual houses or entire green neighbourhoods, the objective is always to pursue the maximum quality standards of energy efficiency and comfort. Further proof of Marlegno's passion for all eco-sustainable things and for the virtues of the circular economy comes in its decision to use only wood from PEFC certified forests, a natural raw material that can be re-used and recycled, that lends itself well to made-to-measure and state-of-the-art uses like those requested by the market.

Over the years, Marlegno has managed to expand its business not just in the north of Italy but to other regions with less of a cultural tradition for timber construction.

In 2020, despite it being an arduous year due to the pandemic, it completed 70 projects and increased its turnover by 20%. And it is still growing today, in search of - though not without difficulties - new professional figures to add to the already existing one hundred enthusiastic employees, expand its spaces, currently at over 10 thousand square metres and open up to Industry 4.0 thanks to a research project developed in close collaboration with SCM and another thirty partners from across Europe.

There are excellent signs from the eco-construction industry, says Angelo Marchetti, company CEO and national President of Assolegno. "The wooden housing market is enjoying a 'Renaissance' thanks to the statement made by the President of the European Commission, Ursula von der Leyen, who described wood as a key construction material, due to its capacity to retain carbon dioxide".

The favourable period is not the only factor behind the growth recorded by the company in recent years. There is another key ingredient in Marlegno's recipe and that is its launch towards innovation, in both the products and processes behind every new construction. "The design stage is the most important one for Marlegno - explains Marchetti -: it is at this point that we manage to intercept all the customer's specific demands and requirements, that are then converted into a product that is extremely comfortable and of guaranteed quality".

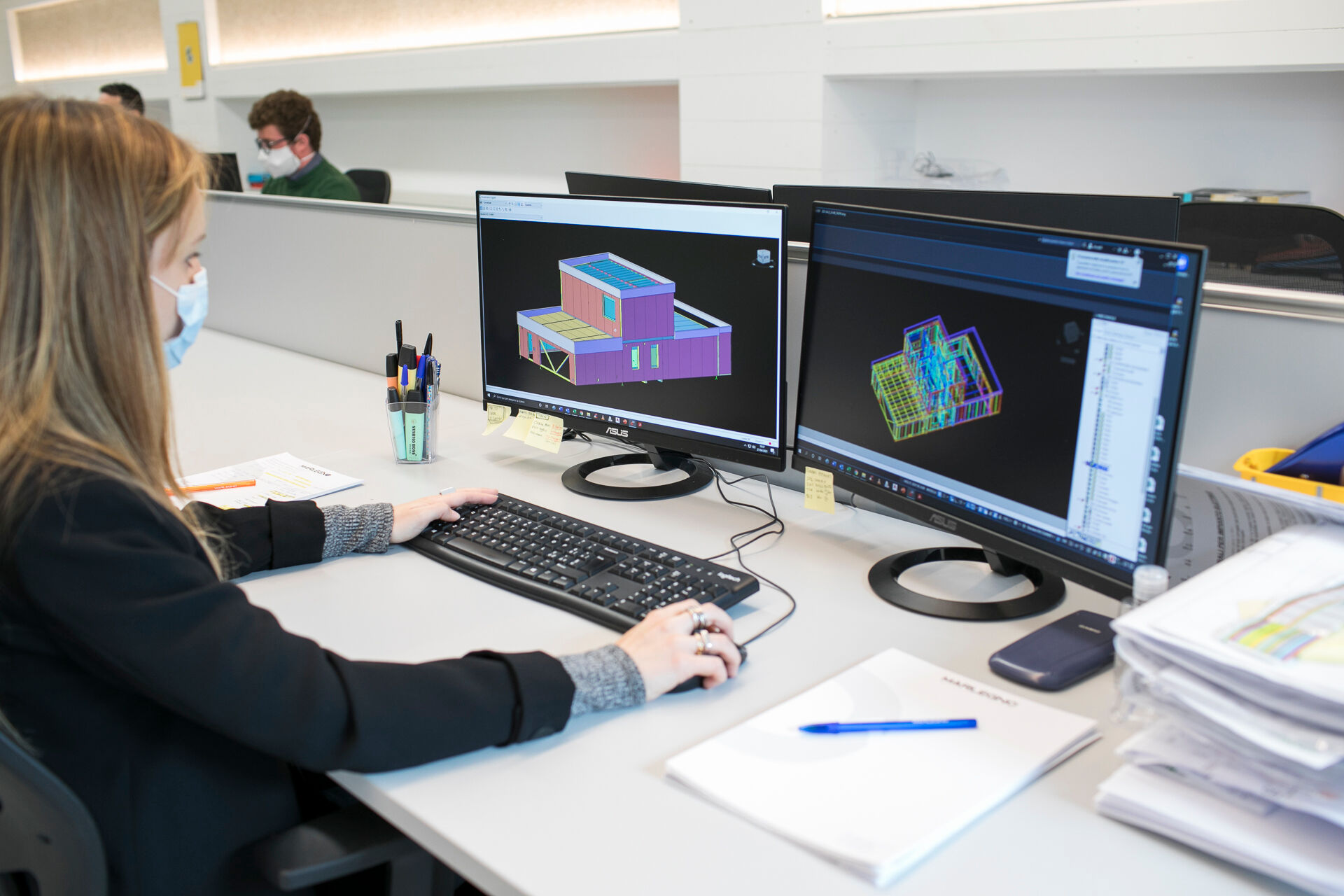

By virtue of this continuous research and development, Marlegno has reinvented itself from a 4.0 point of view. "We transformed our technologies, that we previously used as separate entities, into a connected and integrated unit, one machine after another, together with our Technical Department". adds Marchetti.

The digital transformation process is at the root of that integration concept that we are carrying forward in each one of our sectors: integration of information, data, processes, up to and including the entire business organisation. SCM stands alongside this industrial project.

“For us, SCM is the leader company with whom we can move forward with our innovation planning and production digitalisation" explains Marchetti. "SCM is the leader company that, thanks to its technological know-how, has allowed us to modernise our production to the extent that, nowadays, we even use it as a showcase, to demonstrate to customers just how efficient our technologies are".

Marlegno and SCM work together on the Level-Up project financed by the Horizon 2020 European tender that involves 32 partners from 13 different countries. The project, that was launched in October 2019 running for a total of four years, chose Marlegno as its international case study for the digital transformation of its production processes. The aim is to show how the modernisation of the production machinery via the introduction of innovative technologies, brings with it huge advantages in terms of production quality and process efficiency.

SCM's “oikos x” machining centre is the technological and digital core of this challenge. It has an innovative six-axes machining head unit capable of processing elements that are up to 18 metres long and 1.25 metres wide with millimetre precision. Thanks to the Maestro beam&wall software that is fully integrated with the most common CAD systems used in the market, processes can be virtually simulated as a preview to ensure they are correct before execution, with considerable advantages in terms of productivity, costs and machining quality.

As part of the Level-Up project, vibration sensors have been installed on “oikos x” that allow allow the integrity and efficiency of the machine's operation to be checked and measured, and any faults to be detected in real time, leading to predictive maintenance.

Furthermore, as Alessandro Greppi, Innovation Manager at Marlegno points out, not just “oikos x” but all the company's machinery, will benefit from the implementation of SCM's IoT Maestro connect platform, that will allow for all archive and future data on performance to be recorded, as well as the status of the various technologies, creating a genuine digital register.

"All these operations - explains Greppi - put in place a genuine digital transformation that will not have an effect just on production cycles, but will embrace all the information flows relating to a certain project or order, making them available to all company departments via a common dashboard".

The partnership between Marlegno and SCM, therefore, goes beyond the sale of "oikos x": it is an alliance that leads to new production and organisational horizons, so even the kind of relationship maintained at each stage of the supplier-customer relationship becomes essential. "To us, SCM is a partner that not only provides us with the dependability it has given us - concludes the CEO of this Lombardy-based company - but it is also a reliable partner even at the after-sales stage because it guarantees rapid and continuous assistance over time".

Fill out the online form to be contacted by a salesperson