pack c

(512) 931-1962

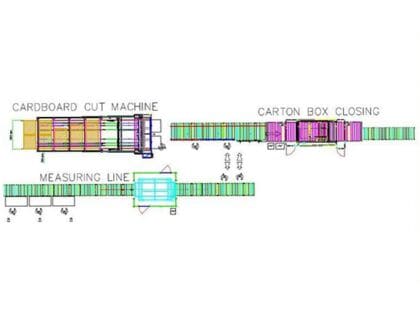

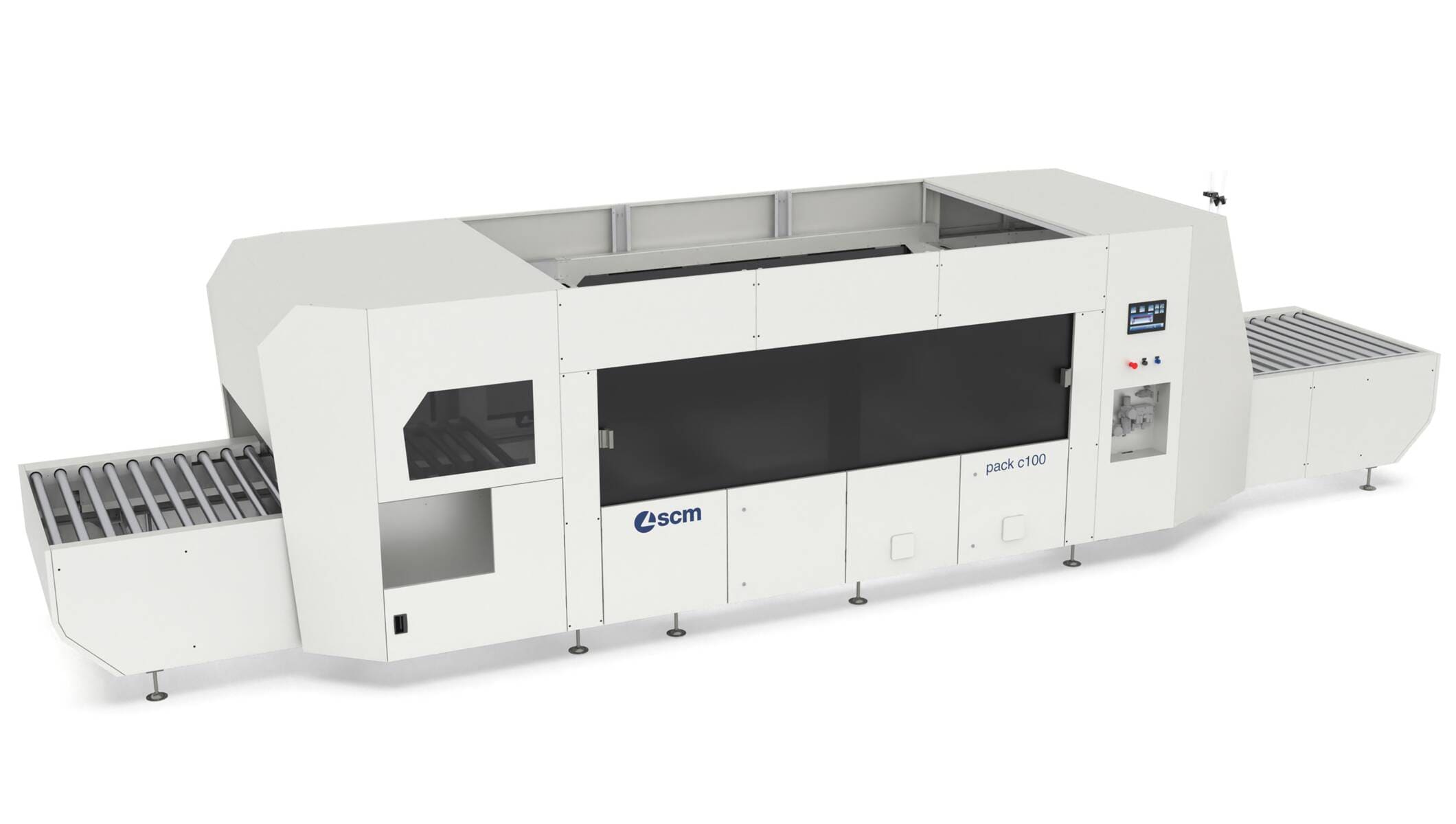

Pack c 100 ist die Lösung zum automatischen Verschließen des Deckels von gestanzten Kartons (FEFCO-Code 410) mit hot-melt Kleber. Das zu verpackende Produkt wird manuell in den vorgeformten Karton eingelegt und der Maschine zugeführt. Dank der automatischen Erkennung der Kartonabmessungen ist es möglich, Verpackungen mit unterschiedlich großen Kartons herzustellen, die nacheinander am Einlauf positioniert werden. Die Lösung ist ideal für Hersteller von Möbelbausätzen.

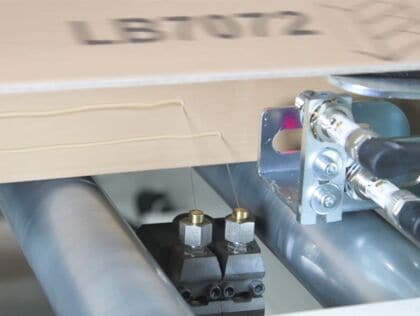

HOT MELT ist die Technologie zum Verschließen der Kartons, die einen hohen Qualitätsstandard der Verpackung gewährleistet.

AUTOMATISCHES LESEN DER KARTONABMESSUNGEN, um den Prozess an die Produktionsanforderungen anzupassen, angefangen von den großen über die kleinen Abmessungen bis hin zur Fertigung großer Stapel.

|

|

|

pack c 100 |

|

Maximale Produktivität (Serienproduktion*) *Der Wert ist für Kisten mit L=1200 mm berechnet |

No. |

8 |

|

Boxlänge min. (Außenmaße) |

mm |

350 |

|

Boxlänge max. (Außenmaße) |

mm |

2500 |

|

Boxhöhe min. (Außenmaße) |

mm |

35 |

|

Boxhöhe max. (Außenmaße) |

mm |

250 |

|

Min. Boxtiefe |

mm |

250 |

|

Max. Boxtiefe |

mm |

1200 |

Bitte füllen Sie das Formular aus, um weitere Informationen zu erhalten