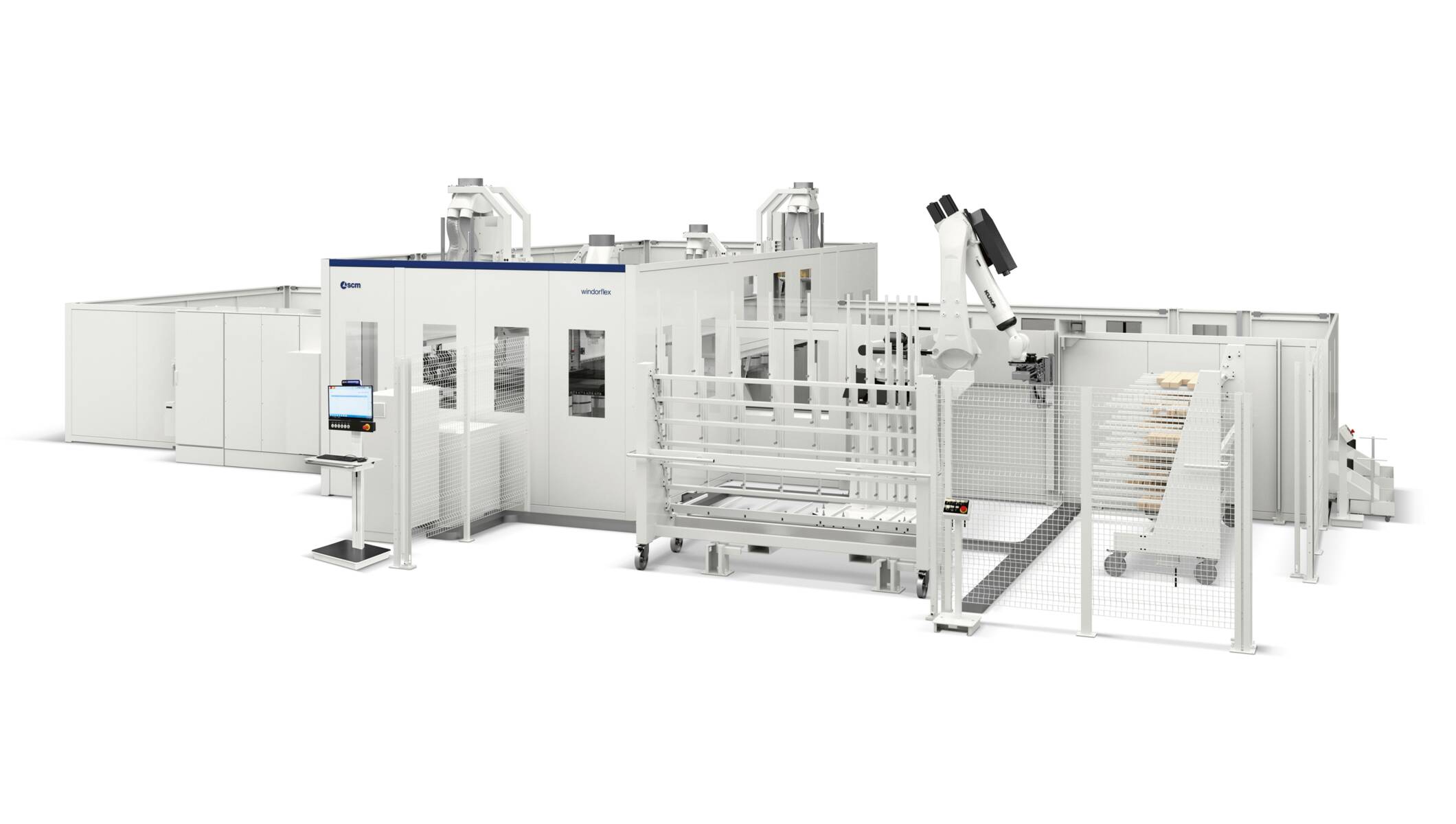

Windorflex 2 is the high productivity SCM machining cell for windows and doors manufacturing.

It is an innovative and high-tech solution designed to perform all the necessary operations for producing window frames, regardless of the type.

The work-pieces automatic loading/unloading system with anthropomorphous robot enable the machine to work autonomously, without the continuous input of the operator.

BEST-IN-CLASS PERFORMANCE

The configurability of the machining units with 4 and 5-axis electrospindles, allows performing all the necessary operations for windows production.

THE ROBOT THAT WORKS FOR YOU!

Unmanned machining: the system is equipped with an anthropomorphous robot that picks up the rough elements and unloads the finished work-pieces on special trolleys.

| windorflex 2 | ||||

| Max. work-piece length | mm | 2 x 3500 4 x 1700 2 x 4500 6 x 1245 2 x 6000 8 x 1160 |

||

| Min. work-piece length | mm | 220 160, with specific cycle |

||

| Max. work-piece width | mm | 260 | ||

| Min. work-piece width | mm | 40 | ||

| Max. work-piece thickness | mm | 160 | ||

| Min. work-piece thickness | mm | 35 | ||

| X-Y-Z axes max. speed | m/min | 100-80-50 | ||

| Standard electrospindles motor power | kW | 20 | ||

| Standard tools stores | n. - positions | 2 x 48 | ||

Preencha este formulário para receber mais informações