Who said the bathroom can’t be the most important room in the house? Market trends convey the exact opposite: this space linked to personal well-being is increasingly becoming a popular place to show off to guests. It can be customised and integrates perfectly with the design in the rest of the home. The choice of furnishings, therefore, plays a key role. As a company with more than 100 employees and a turnover of 18 million Euro, Gruppo Geromin is well aware of this. Its Hafro, Sauna Vita and Geromin brands have become a benchmark for the Made-in-Italy production of bathroom and wellness furnishings.

A business based in the province of Venice since 1945, it operates all over the world with a widespread, consolidated network which works alongside the client from the design to delivery stage, satisfying needs in every sector, from private to public, right up to contract work.

Complete shower systems, jacuzzi tubs, small design pools and shower units with steam functions enhance bathrooms in private homes and resorts, together with Turkish baths, saunas and spas: without forgetting about furnishings for laundry rooms, which the Gruppo Geromin’s showroom displays as a truly fashionable room.

“Right from the outset, we made our mark with the quality of our materials and manufacturing where finishing, textures and materials coexist in harmony”, explains the owner, Carlo Geromin. “In specific terms, with regard to the production of bathroom and laundry room furnishings, we offer a careful selection of veneered, melamine and lacquered finishes, as well as solid wood components to customise the room and coordinate every stylish detail”.

What does today’s market want? Geromin has no doubt: “Clients are increasingly interested in modern design wellness products, fashioned to offer authentic moments for relaxation. Shower units with steam functions, jacuzzi baths with bluetooth for music, colour therapy and even built-in modules with sauna, Turkish bath and shower...are products we offer with the option of coordinating when it comes to complete fashionable bathroom furnishings”.

Thanks to a wide range of textures and materials, anyone choosing Gruppo Geromin can achieve completely tailor-made bathrooms with Made in Italy products. “Quality, product lifespan, expertise, innovation and research, as well as the determination to create state-of-the-art things: this is what gives us the edge over our competitors”.

There are so many aspirations and demand from the market is becoming increasingly more sophisticated. How can we satisfy this? Carlo Geromin points out the need to equip themselves with innovative technological solutions.

“Guaranteeing a top-quality product to the end client is essential for us and this is why we continue to invest in research and innovation” says the owner of the Venetian group. “The technological revolution definitely changed our company and a new synergy developed between man and machine, aimed at making the most of these two worlds: during the production process, the machine and operator perform different but closely connected jobs, each one making the most of their strong points”.

Production efficiency also translates into eco-sustainable processes. “As a Group, we make sustainability one of our key values and precisely for this reason we aim to create as little impact as possible on the environment, with respect for our region. We are convinced that, from the outset, a product needs to be devised and designed to create as little impact as possible: this means offering a product that lasts over time, created using a material with a low energy and low environmental impact”.

The Gruppo Geromin recently renovated its Hafro plant at San Stino di Livenza, in the province of Venice, and with help from SCM, fitted state-of-the-art “Industry 4.0” machinery.

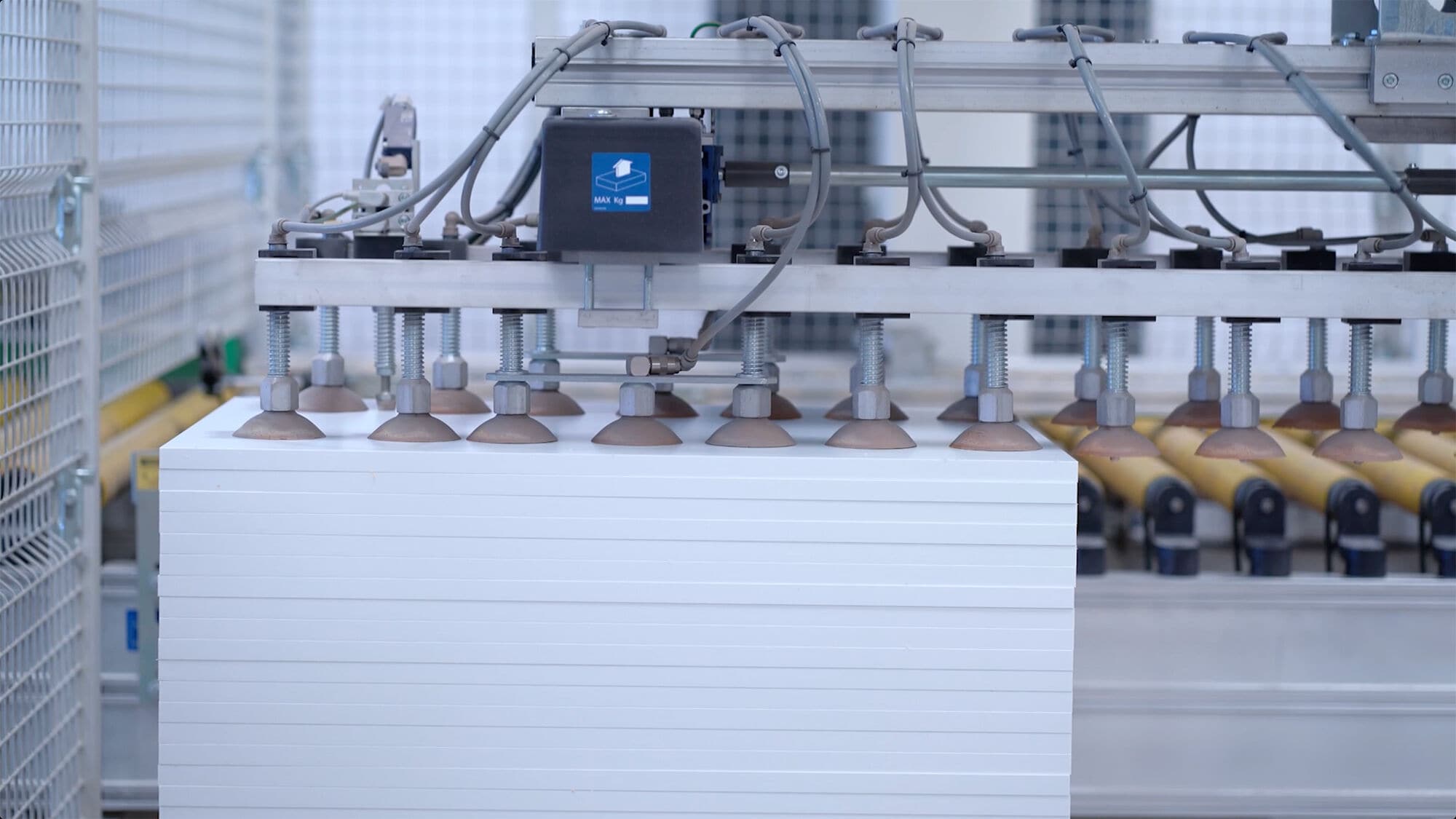

A cutting cell consisting of a gabbiani g2 panel saw complete with flexstore elr automatic magazine and mahros runner automatic unloading system meets these requirements. A solution which allows you to achieve high production flexibility, in line with the extensive customisation of the company’s products, as well as high productivity and machining quality.

Gabbiani g2 was designed to guarantee top performance in an advanced context of just-in-time productions. The machine’s performance is reinforced by the optional internal rotation to handle any cutting outline without the need for operator intervention and the automatic labelling machine which attaches the labels directly onto the panel in masked time.

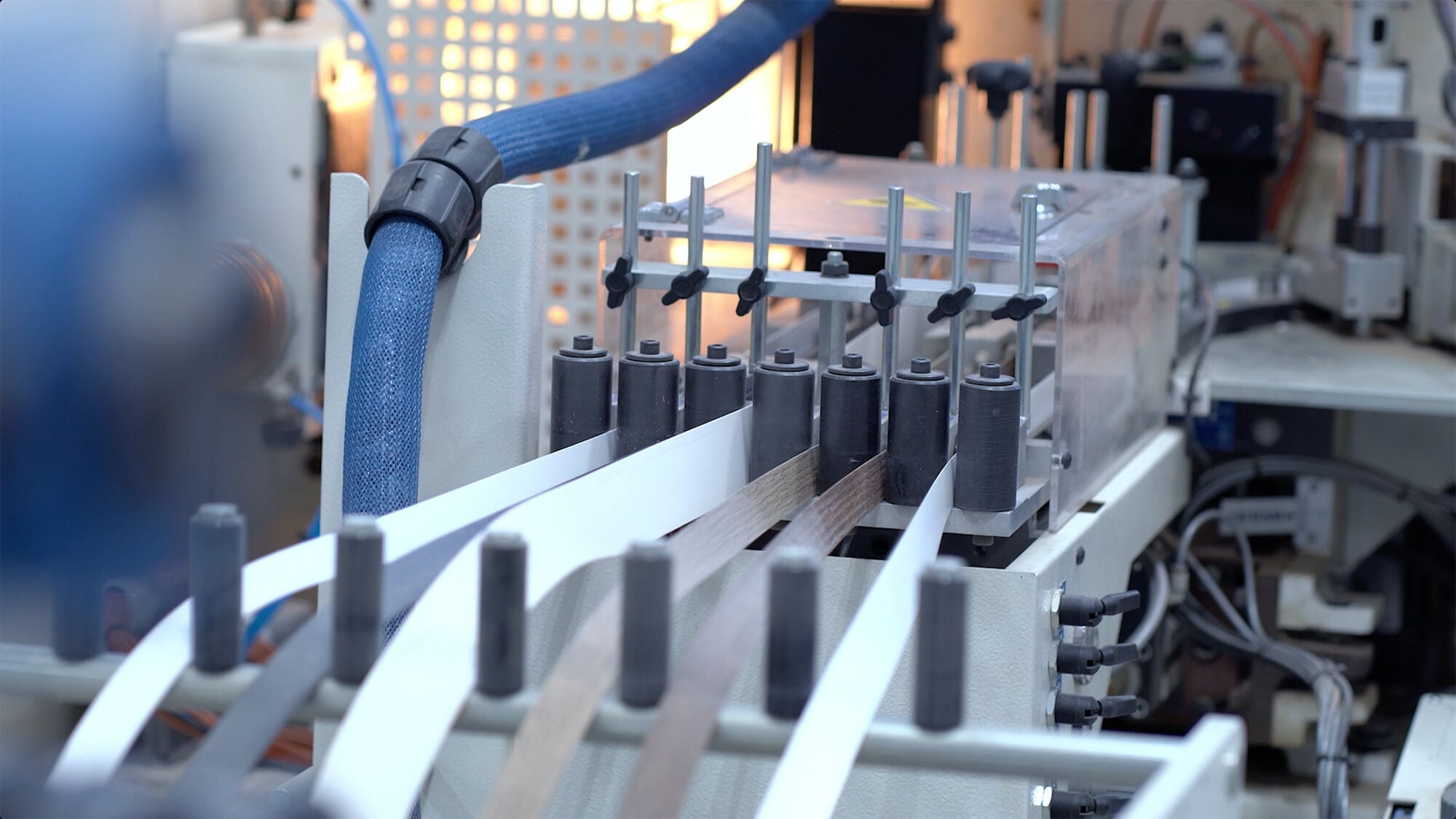

The cut panels then move on to squaring-edgebanding, a process which is handled by an innovative system with the stefani evo c squaring-edgebanding machine capable of guaranteeing more efficient machining and higher quality compared to what the company managed to achieve in the past. The panels are loaded automatically with a mahros runner single-station feeder, after which the panel is squared and edged in two stages, one longitudinal and the other transversal. It is possible to machine standard chipboard panels as well as MDF ones veneered with different kinds of coating (melamine, CPL, HPL, opaque edges) and even ones that are not very thick.

The squared, edged panels are drilled, dowelled and offloaded onto other machines, then unloaded at the end of the process, again automatically, with another SCM mahros runner system.

At this squaring edgebanding and drilling stage, all the machines and automation systems are controlled by a single supervisor software from the Maestro active watch range so that the work programs, flow of materials as well as the relative reports on production and diagnostic performance can be fully traced.

Gruppo Geromin also uses a stefani kd single-sided edgebander to process smaller batches with an automatic panel return system which means the entire edgebanding cycle can be handled by a single operator. This solution is also highly flexible, thanks to machining units with electronic axes which allow two different kinds of radii to be set automatically, thin edges and solid wood strips up to 12 mm.

“Our ongoing research aims to uncover the most recent technological innovations to provide a constantly state-of-the-art bathroom and wellness proposition. This is why we chose SCM as our partner. This state-of-the-art technology allows us to use a “Just-in-time” industrial management model. Three top-performing machines in terms of quality and machining speed, which guarantee flexibility, accuracy and a perfect cutting finish. This allows us to machine any kind of panel and be ever-more flexible, increasing speed at the machining stage of made-to-measure requests”.

A guarantee of quality, flexibility, top-quality technology and customer care: “this is why we chose SCM technology”.

Fill out the online form to be contacted by a salesperson