SOFTFORMING – FURNITURE PROCESS

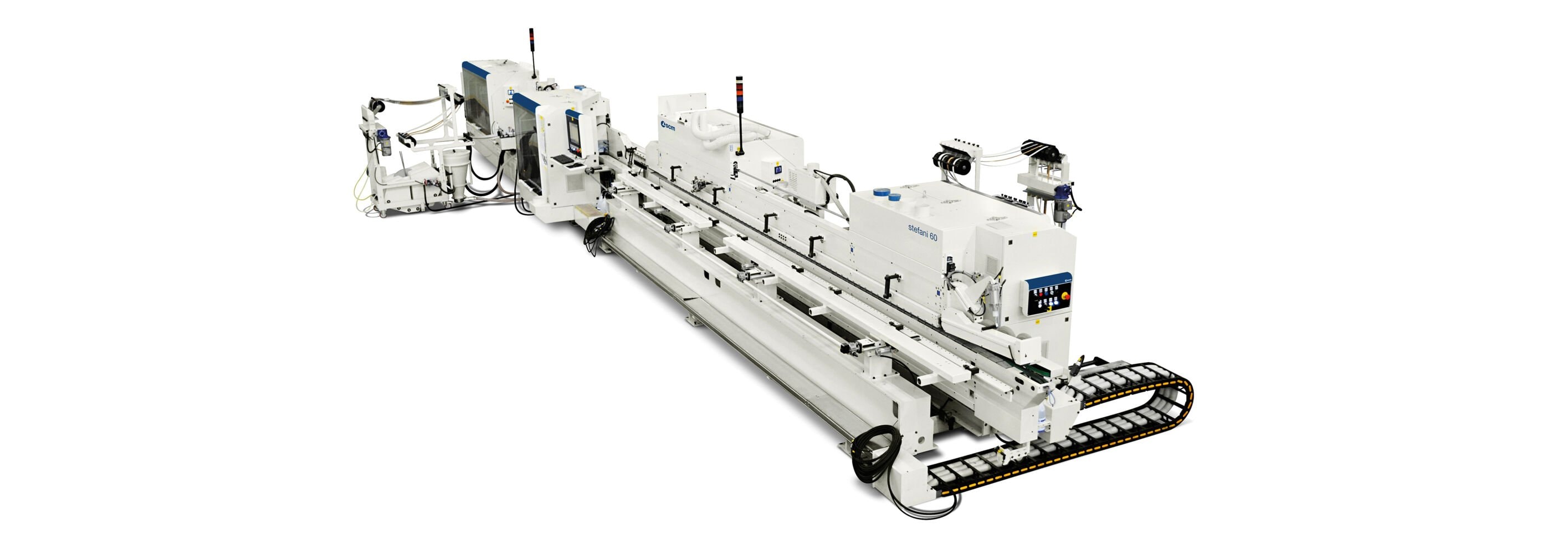

Now you can free your imagination thanks to the softforming edge banders produced with SCM’s excellent know-how and guaranteed solidity.

Easily model new shapes and perspectives with finishing quality never seen – nor touched – before.

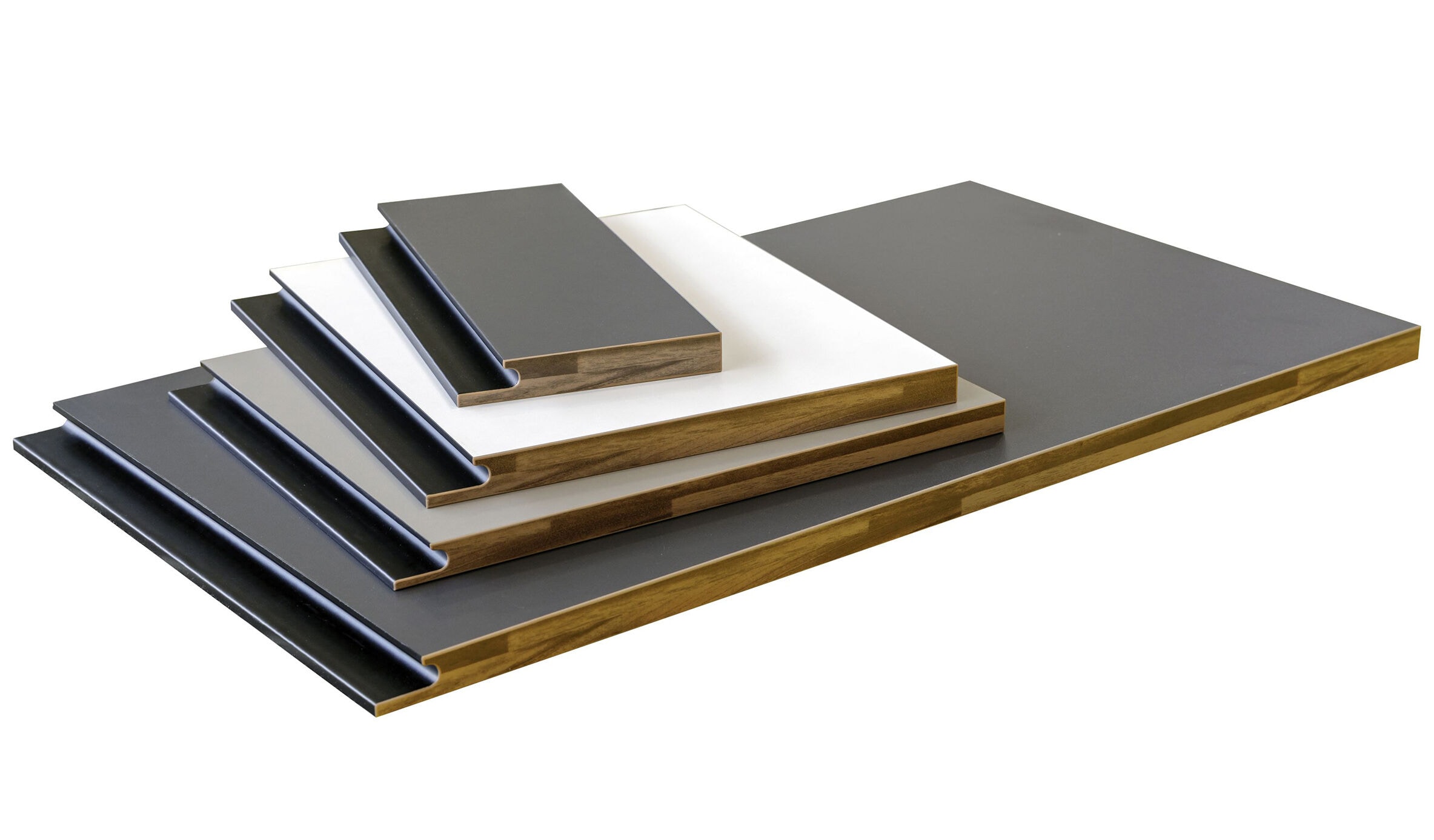

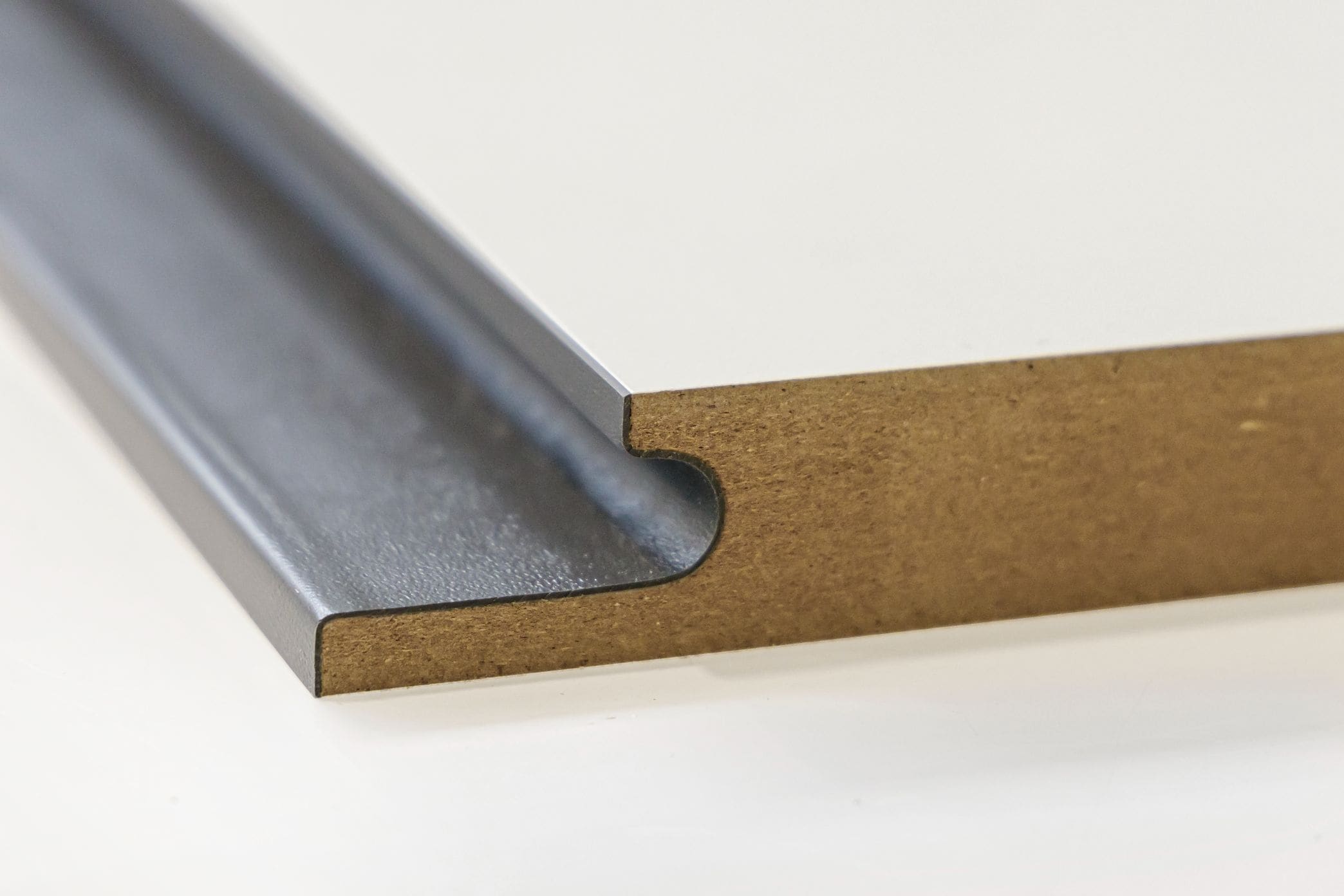

Here are just a few examples of achievable profiles.

STEP profile

J profile

45° profile

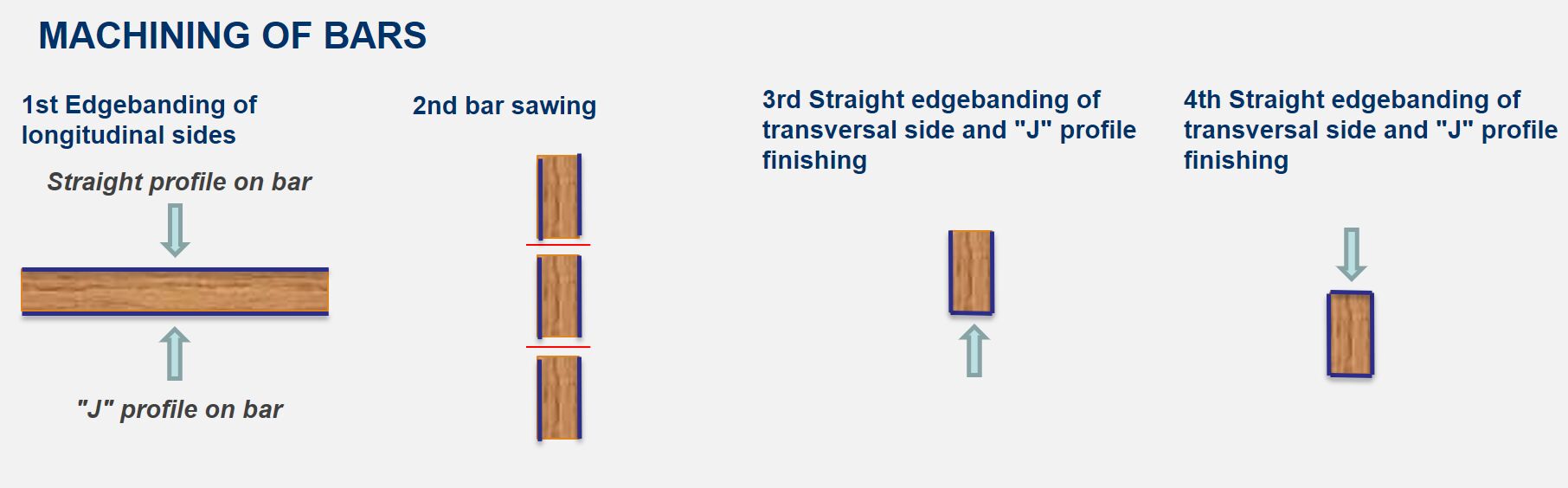

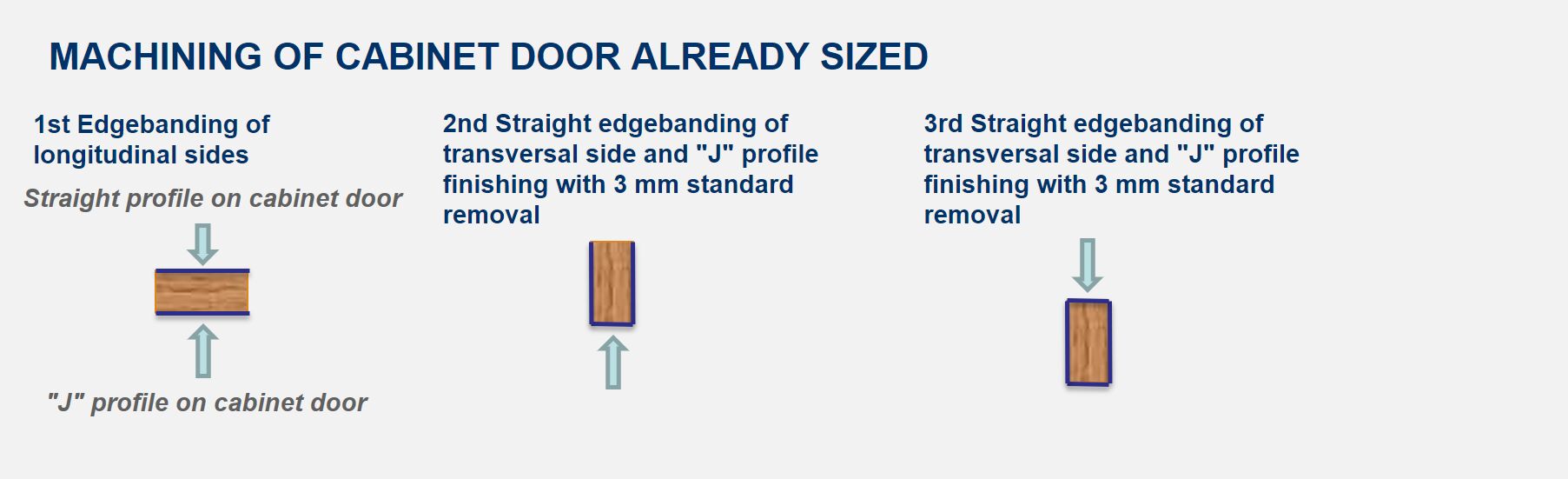

THE RIGHT SOLUTION FOR ANY KIND OF PROCESS

Possibility of machining longitudinal bars with subsequent sawing and edgebanding or cabinet doors already sized.

DIFFERENT MATERIALS – NO PROBLEM

A complete catalog of solutions is available. Chipboard, MDF panels, ABS, PVC, PP edges, EVA and PUR glue. Thickness, finish, decoration are no longer a design limit.

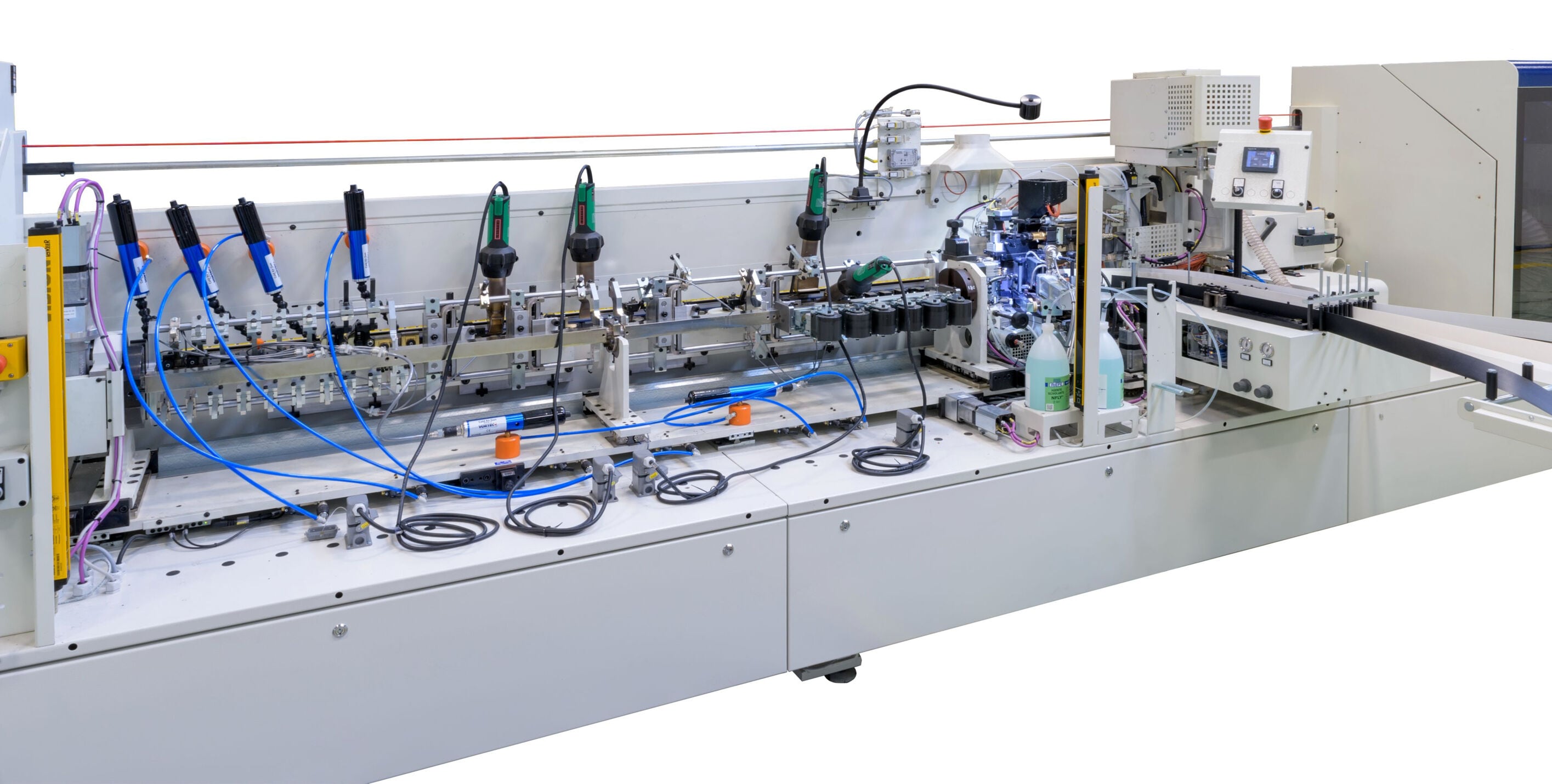

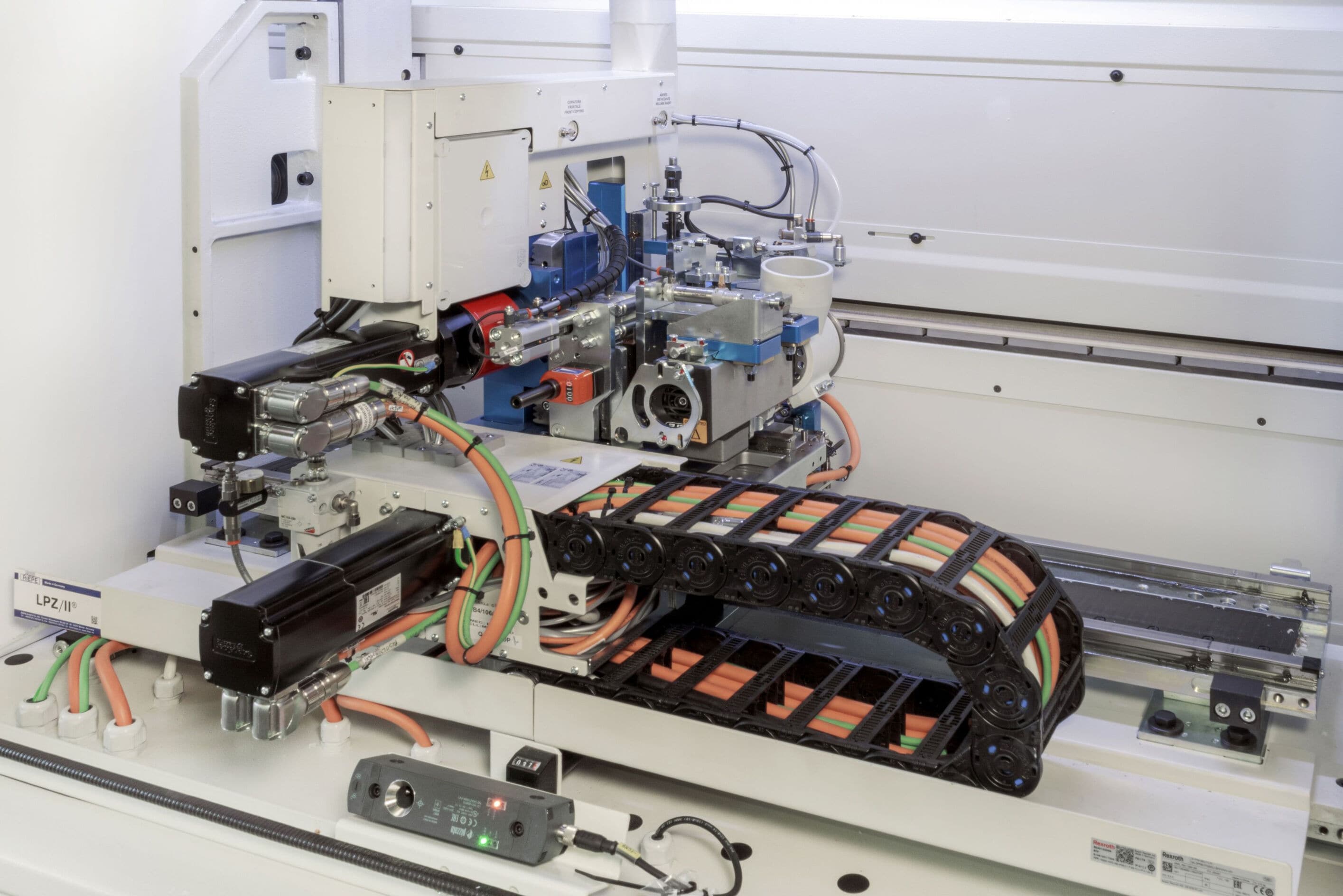

DEDICATED WORKING UNITS

The gluing unit has an edge pressure zone that can have different lengths, 1m, 1.8m, 2.4m set up with sectors equipped with cooled pads or a combination of pads and rollers depending on the profile to be achieved and the material used (panel/edge/glue).

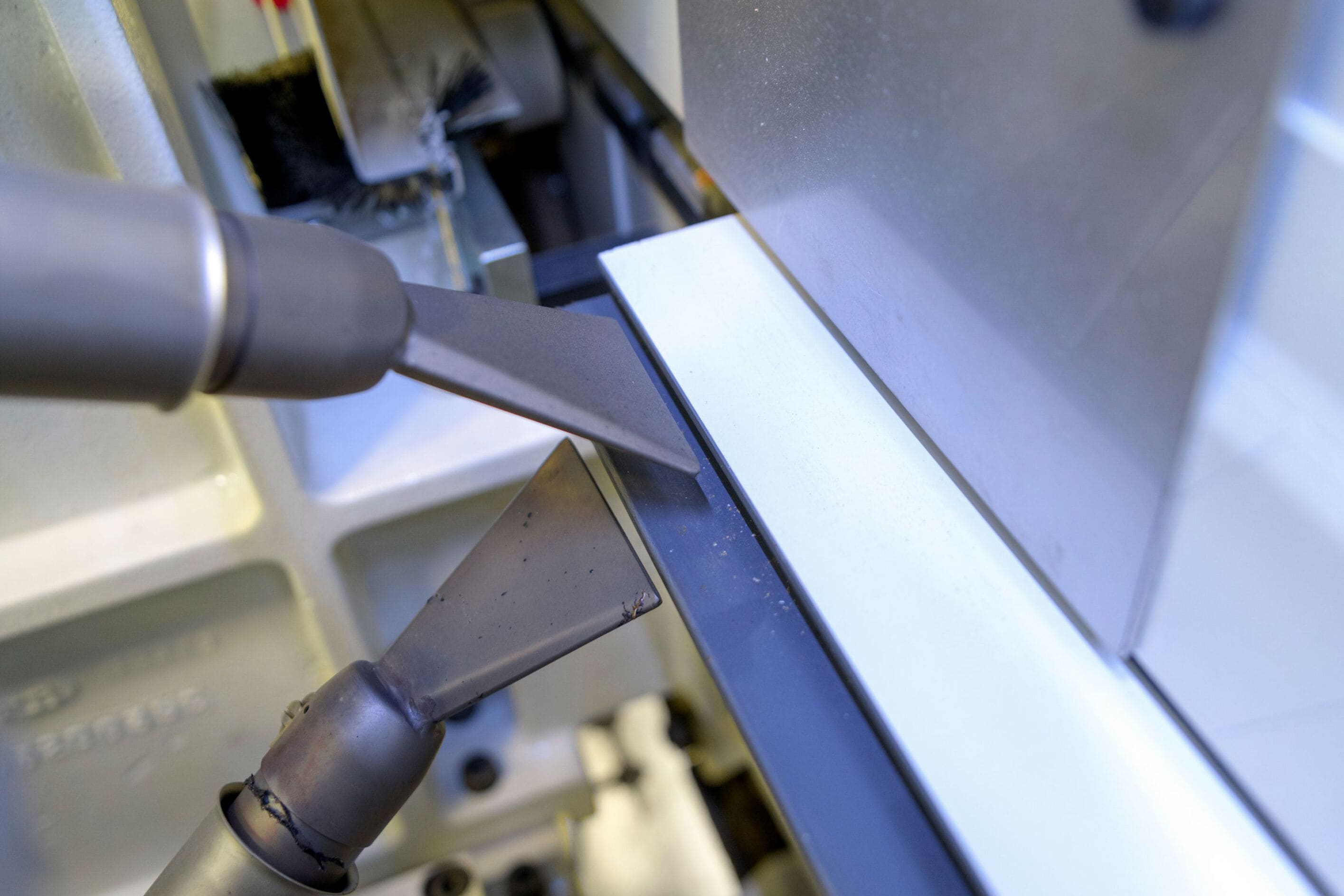

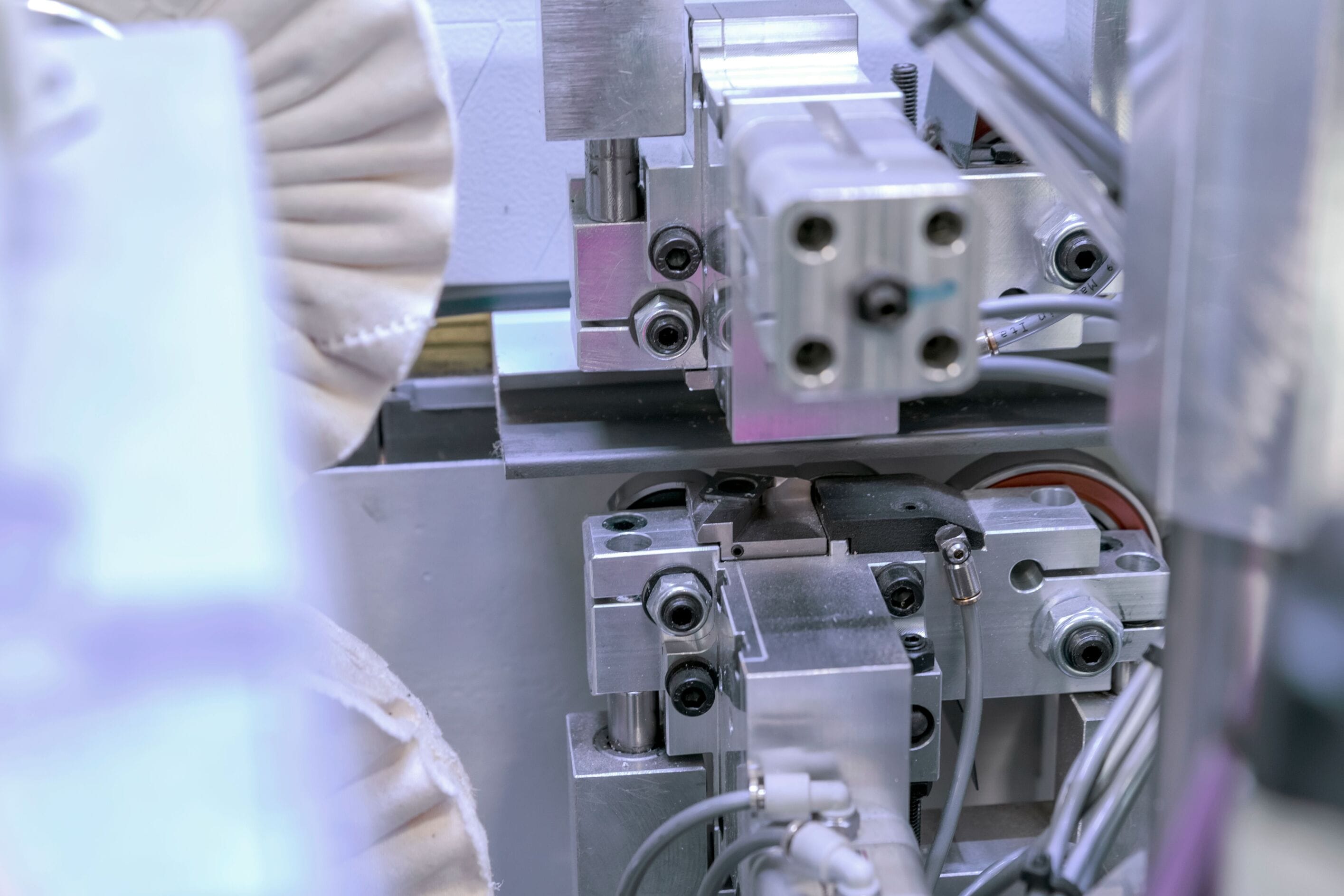

The end trimming unit has been designed with a new cutting geometry for better finishing the front and rear of the panel. It reduces waste when the panel is subsequently machined transversely.

The finishing of the transversal side of J and C profiles is performed with the dedicated Round J-side electronic rounding unit.

For an excellent finishing, the edge scraping and brightening units are equipped with electronic axes for a flexible and automatic positioning depending on the type of profile.