CMS smartline: the ideal waterjet machine for processing laminated safety glass

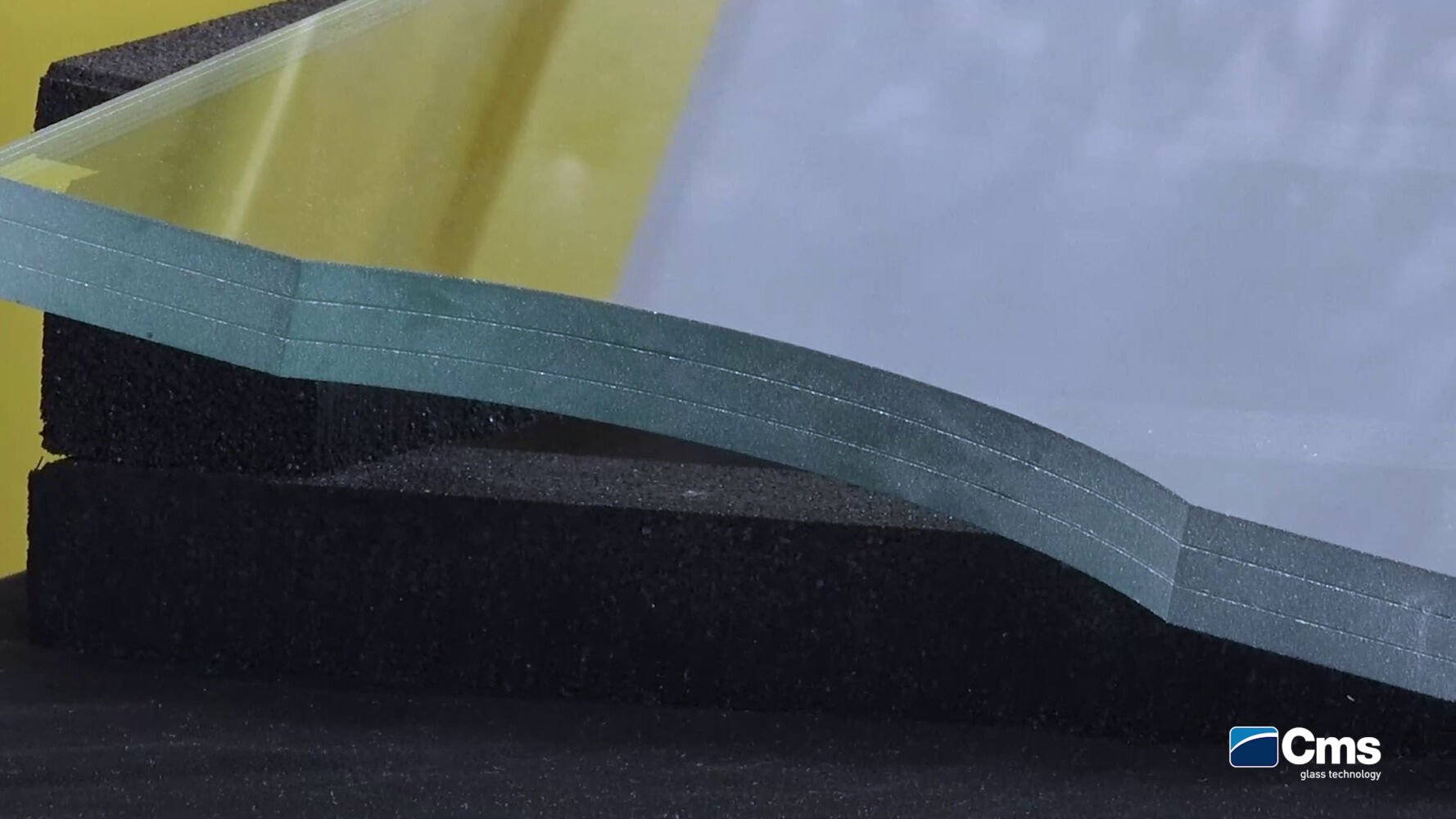

2024. márc. 28.Cutting thick safety glass without compromising on cycle times can be quite a challenge, especially if the glass is thicker than 19mm and has a curved shape.

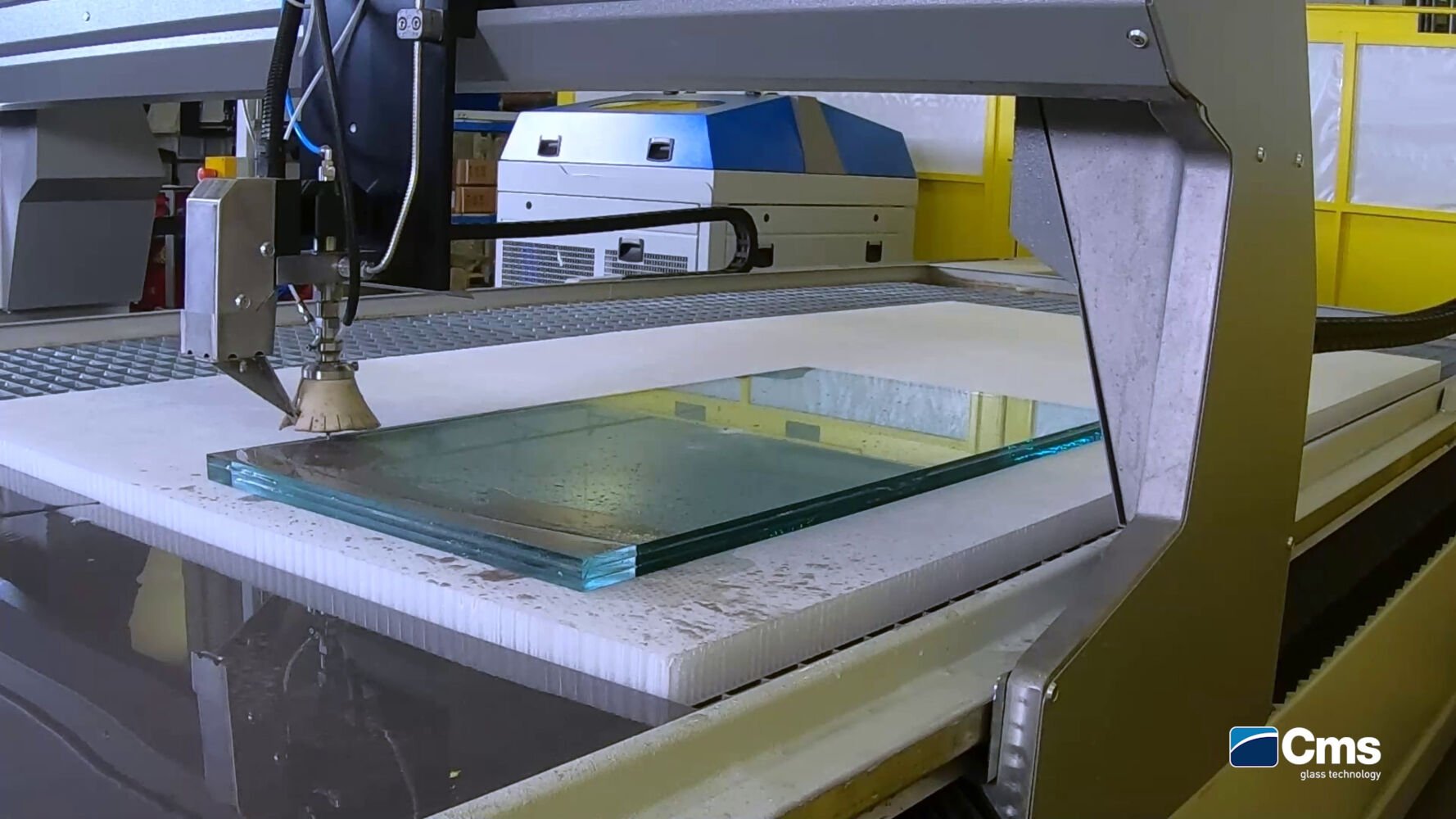

With this in mind, Cms offers an extremely cost-effective solution. Cms has specifically developed the smartline, the ultimate waterjet cutting system for glass available in 3 and 5-axis configurations.

EXCLUSIVE BENEFITS

- Up to 33% faster cutting cycle times with 50m/min rapid speed and 3 m/s2 of acceleration- the best in its category

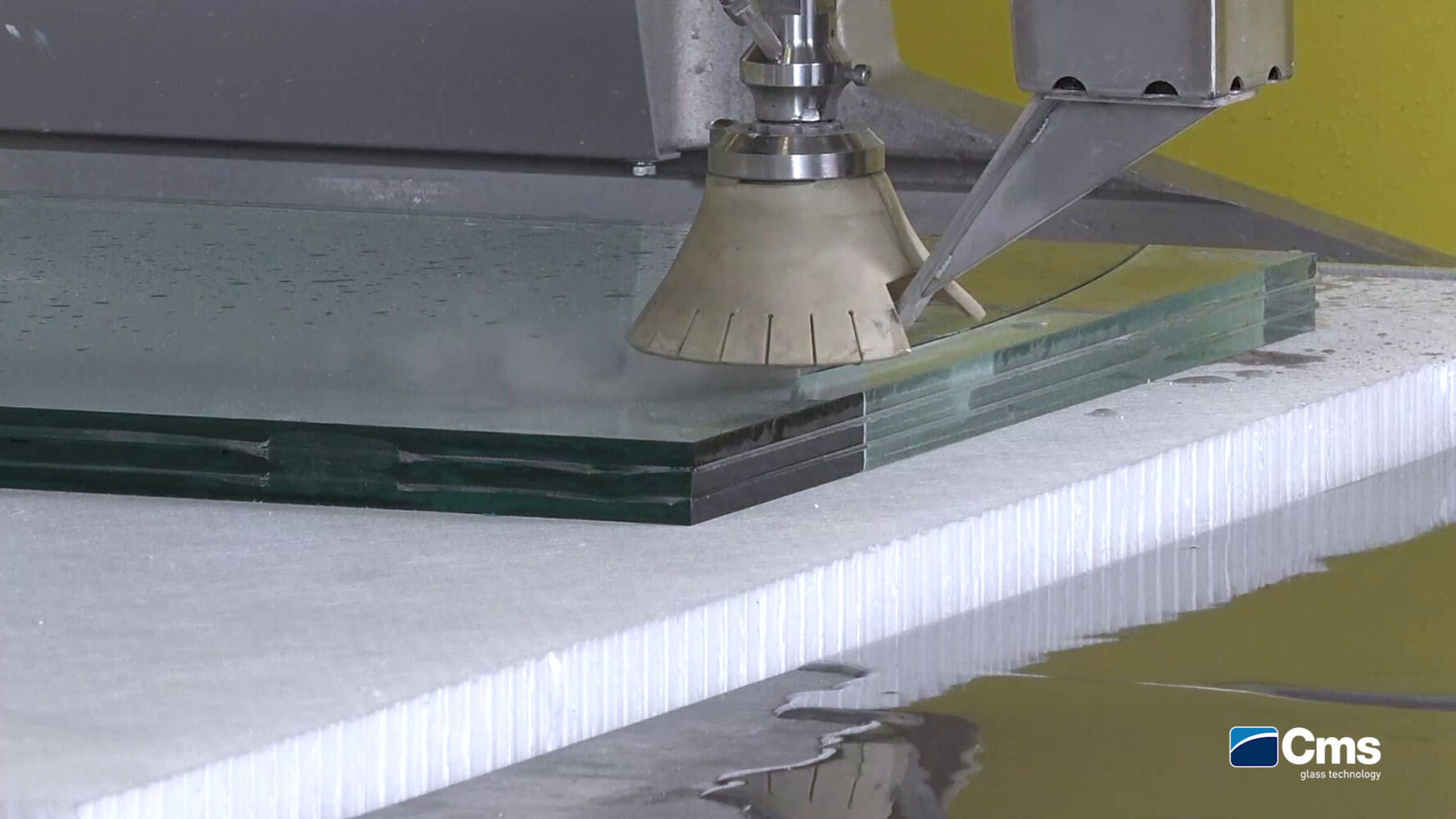

- +/- 0.07mm positioning accuracy

- +/- 0.05mm repeatability

- Best in class price/performance ratio

The machine can process up to 4m x 2m glass sheets, with a minimum allowance of 0.5mm by cutting them with water and abrasive at 185mm/min, ensuring consistent quality standards.

The cutting head reaches an impressive speed of 50m/min with acceleration of 3m/s2, setting the highest standard in its category.

CMS smartline offers a sturdy and compact frame, integrating linear guides, and class H5 rack-and-pinion movement system on the tank, capable of withstanding high speeds and acceleration without compromising cutting accuracy and repeatability.

The durability and reliability over time of the kinematic components are ensured by the NC managed automatic lubrication system.

A system of thermo-welded techno-polymer bellows protects the guides form water and abrasive erosion during cutting while the protection of the bridge is ensured by a sheet metal labyrinth offering greater resistance to the direct action of reverberations.