Within the CMS Glass Business Unit, the Engineering department plays a strategic role in developing advanced technological solutions for glass processing.

In the world of glass processing, innovation runs fast: machines become more and more evolved and efficient. But as the technology supply grows, it is increasingly difficult to find skilled operators capable of exploiting their full potential. The result? Risk of inefficiencies, machine downtime and extra costs.

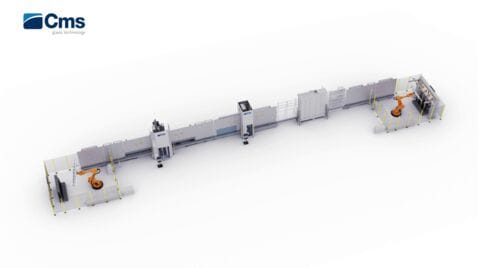

For over 25 years, CMS has been developing special machines and automated lines for glass processing, offering tailor-made solutions designed to maximize efficiency and productivity. The systems built by CMS guarantee edge and internal processing with maximum precision and meet the specific needs of each customer in terms of space and cycle times.

From June 12 to 14, our Zogno (BG) facility hosted the CMS Open House: three days of innovation, featuring live demos, technical insights, and meetings with customers and partners.

CMS vertical machining centers combine precision and quality with the productivity and versatility benefits typical of vertical machining. With CMS Connect, the innovative industrial IoT platform, they monitor and analyze data in real time, turning it into strategic information to optimize performance and reduce operating costs.

CMS Glass Technology has consolidated its presence in the laminated glass sector, distinguishing itself for its innovation and the development of advanced solutions. It has successfully addressed the challenges related to laminated glass cutting, proposing technologies that improve efficiency and precision.

CMS Glass Technology renews the waterjet cutting experience with easyline and e-pump, the perfect solution for those looking for versatility, precision and efficiency. Now, thanks to the integration of the hybrid pressure intensifier, the system guarantees even higher performance, reducing consumption and maintenance.

CMS machining centers with 3 or 4 and 5 axes for the processing of flat glass, both thin and thick, float or laminated and bent glass.

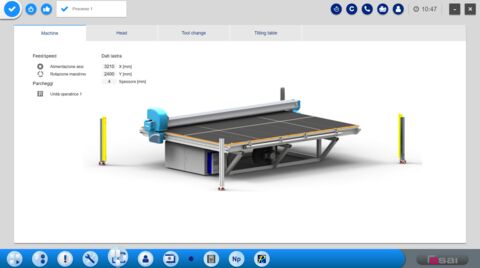

EasyGLASS CAD-CAM software for glass fabrication simplifies the process, making it intuitive and accessible to everyone. Available for all CMS glass machining centers, EasyGLASS offers an optional package that can be integrated with automatic CAM software to implement an entire project in three simple steps:

CMS sprint is a 5-axis CNC cutting machine equipped with a diamond disc, designed to boost productivity in the processing of laminated, fire-resistant, or safety glass. Sprint enables the cutting of square, rectangular, or polygonal glass, performing both vertical cuts and 45° inclined blade cuts.

Near Rouen in Normandy, you can find Normanver, a French business that has been a leader in the glass sector since 1986, with extensive operations in northern France. In the Normanver factory, they produce and process multiple types of glass from the beginning to the end of the production chain: flat, safety, tempered or laminated glass, insulating glass with thermal or solar control and decorative glass.

CMS commitment towards constant growth in the digital field is concretely transformed into two latest generation solutions: CMS Active and CMS Connect, to optimize the operational efficiency and productivity of glass processing machines.

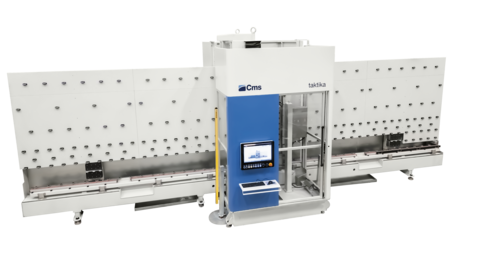

CMS taktika is the compact vertical machining center developed by CMS for the greatest flexibility in small spaces. The project was conceived for small and medium-sized glass factories that need to increase their efficiency, and is also ideal for larger companies that need the flexibility to manage small batches of glass.

Cutting thick safety glass without compromising on cycle times can be quite a challenge, especially...

Flat glass sheets offer a wide range of possibilities for creating interior design furnishings: banisters, stairs, elevators, floors, walls, doors, kitchen worktops, hobs, sinks, tables, mirrors, shower walls, shelves, chests of drawers and cupboards. How does CMS fit into the glass fabrication sector for interior design?

More than 100 horizontal and vertical seaming machines were sold worldwide by CMS Glass Technology.

CMS electa is the new 3- or 4-axis CNC machining center for processing flat glass, whether thick, thin, laminated or bulletproof. CMS electa features a small footprint and the largest work area in its category. It can perform many types of machining: rough and polished edge grinding, edge polishing, drilling, milling, cup wheel polishing, diamond disk cutting, diamond and smooth disk engraving and 5° polished chamfering with a cup wheel.

For over 25 years, CMS has been developing and manufacturing special machines and automated lines...

The insulated glazing market is innovating to ensure the best thermal efficiency without increasing the thickness of the insulated glass units.

Confirm your attendance by registering at this link: https://lnkd.in/drHAAugj or by scanning the QR code.

The new "CMS Active" software interface has been specifically developed to streamline the management of both vertical machines and the latest CMS cutting tables. With its optimized design, it offers a more intuitive user experience, making it simpler for operators to use. Supervisory Control and Data Acquisition (SCADA) software has been designed to provide operators with immediate oversight and control. This software effectively monitors and manages all the primary components of a machine.

We had the great pleasure of spending a day in Edil Vetro, the company founded by Tommaso Sabatino and an institution operating in the glass sector since 1993. Edil Vetro was founded in Montesarchio (BN) as a glass factory specializing in insulating glass units for windows and has grown over the years to expand its production range to include doors, balustrades, cantilever roofs and glass design.

In glass fabrication plants, moving glass from racks to processing machines is necessary, even if this work has low added value, it can be dangerous if the glass breaks and it can sometimes be a weary job.

The use of processed glass in various sectors, such as architectural and interior design, often requires non-rectangular shapes and specific processing methods, such as creating holes and notches in the glass itself, as well as grinding and polishing its edges.

Cms aura is a dry, vertical seaming machine designed specifically to process edges without using water (dry seaming). Aura can be used as a stand-alone machine, or in line with a vertical washing machine and is the ideal machine to be included on a double-glazing line

agil tr is the most compact, versatile cutting table ever produced.

What are IG Units? A window fitted with insulated glass units is produced with two or more panels of glass separated by a vacuum space or filled with inert gas to reduce the transfer of heat from one side of the window to another. IG’s also provide improved acoustic insulation.

Thanks to the new CMS maxima machining center and the advanced system developed by CMS created from a combination of three elements (specific 3d software, laser detection system of the models and new locking system for the glass with suction cups in different positions) BCE Glass Industry is the ideal partner to its demanding clients in the marine, automotive, aerospace and architectural world.

A fully automated cutting line involves the glass sheets being picked up from racks, cutting them to size and lastly the break-out. Depending on the final sizes of the glass to be unloaded, the line can be overseen by a single operator. CMS’s runner line is available in two sizes: half Jumbo and Jumbo.

Mistral Optical is a company producing, on average, 50,000 pairs of glasses a month. It is located in Quero Vas in the region of Belluno, global center for eyewear. Working on a pair of glasses is a complex operation that needs to find the perfect balance between expert manpower and automated work done by machines. There are about 30 intermediate stages. Knowing exactly at which stage a product can be found in the various processes, at any given time, is the turning point in the entire production chain; representing real added value in the service offered to one’s clients. Precisely with this in mind, the company decided to connect the numerous CMS machines together, from the latest additions to older versions.