tecnocut waterspeedy s

(512) 931-1962

WATERJET CUTTING SYSTEM

Tecnocut Waterspeedy S is a waterjet system designed specifically for the high-speed processing of plastics capable of providing an exceptional materials, layered materials, industrial seals and technical material. The advanced design of its structures, the result of continuous investments in R&D and the sophisticated technological solutions adopted, provide precision over time, speed and flexibility to guarantee an exceptional level of finishing and unparalleled accuracy.

- The exceptionally high dynamism, combined with the possibility of working on several cutting heads guarantee a very high level of productivity and competitive costs compared to conventional cutting systems.

- Loading/unloading while the machine is running thanks to an automatic, built-in pallet change system.

- Large scale work areas for maximum productivity freedom.

- The compact design allows for movement and transport without removing any mechanical part, guaranteeing reduced times for putting it back in service.

- Programming system dedicated to the optimized generation of the cutting path. Based on interactive software and touch screen to manage all the CNC functions. It allows the cutting program to be created starting from the integrated software and a DXF file by reducing the cycle time to a minimum.

NO ONE IS AS FAST IN WATERJET CUTTING

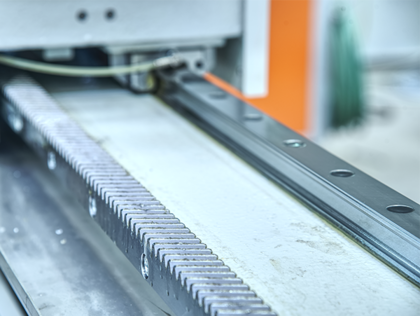

Racks and helical pinions ensure unparalleled performance with fast speeds of 70 m/min and accelerations of 7 m/s2.

PRODUCTIVITY INCREASE UP TO 85%

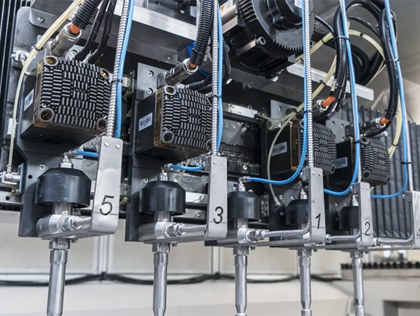

Cutting configuration with from 3 to 7 pure waterjet heads with 3-axes and NC-controlled automatic spacing, to meet production requirements related to machining nesting of foam sheets and rolls.

CUTTING ZONE PROTECTION FOR A CLEAN AND QUIET ENVIRONMENT

Soundproof cabin to protect the cutting area and to prevent any contact with moving mechanical parts and leakage of water and dust.

| MODEL | 1630 |

| X AXIS | 3000 mm / 118 in |

| Y AXIS | 1600 mm / 63 in |

| Z AXIS |

300 mm / 12 in (200 mm / 8 in with 5-axis head) |

| B AXIS | +/- 60° |

| RAPID SPEED | 72 m/min / 236 ft/min |

| ACCELERATION | 6 m/s2 / 19 ft/s2 |

| SUPPORT PLANE | 3000 x 1600 mm / 118x63 in |

| OVERALL DIMENSIONS WITH LIGHT BARRIERS | 10300 x 4956 mm / 405x195 in |

Fill out the online form to be contacted by a salesperson