News

Marbrerie Retegui Bergez and CMS: the innovation of tradition

In the south of France, within easy reach of the border of Spain, you can find "Marbrerie Retegui Bergez", a family-run company of marble masons. We are welcomed by Jean Retegui, responsible for measurements, drawings and coordinating production and installation activities.

What is there beyond top of the range?

Often, when you want to achieve the highest possible productivity, you focus on owning the highest performing machine. Owning a top-of-the-range machine is an important step toward excellence, but productivity is also affected by factors unrelated to the machine.

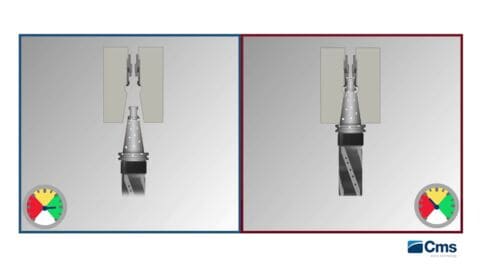

Tool release, what to do? CMS has the solution for you!

In the world of stone fabrication, productivity is essential and tool release failures can compromise work quality and cause the stonemason to lose money. CMS is committed to offering its customers the most suitable technologies to meet their different needs, so it provides both hydraulic and pneumatic tool release solutions.

Brembana jetpower evo: the excellence of tradition

In the world of pressure intensifiers for waterjet cutting, CMS stands out by offering the market a unique model featuring a parallel-cylinder design. This type of architecture can maintain an output pressure with a constant signal, without the need to install an additional downstream accumulator, a requirement typical of the opposing-cylinder intensifiers on the market.

CMS brembana electa: at the peak of productivity!

Brembana electa is a 3- or 4-axis machining center for machining stone, featuring a unique combination of compactness, large working area and productivity. Brembana electa extends the CMS range of machining centers, while maintaining high quality standards and offering a more compact and simple alternative to the other models in the series.

Here are the 5 reasons to choose brembana kartesia for your fabrication needs!

1. Brembana kartesia is the most advanced CNC machining center with 3/4 interpolated axes for fabricating stone items. It can perform any type of contouring, drilling, milling, engraving and polishing with high precision and execution speed.

BF STONE and CMS: a synergy for maximum efficiency

At BF Stone in Fossò, in the province of Venice, we're greeted by Daniele Barbiero, one of the owner-partners. He explains the origin of the brand name: "B" comes from the family surname, Barbiero, and "F" from Formenton.

Get the best possible level of polishing with DPAWC!

The CMS brembana kosmos bridge milling machine is ideal for cutting and shaping stone. With its ability to machine slabs and blocks, it allows for the creation of custom pieces, making it ideal for applications such as flooring, gravestones, and stone pavers.

Perfect Joint: the new tool for the perfect fit!

Are you cutting a slab of natural or synthetic stone to make a kitchen worktop, and after cutting you discover that the two pieces have significantly different thicknesses when you fit them together? The result is completely unacceptable, for both you and your customer! And now what?

Effortlessly Process Large Marble Blocks!

Transporting large marble blocks to and from the machining center can be challenging due to their size and weight. Initially, the block is heavy, and after being sculpted, it becomes lighter and more fragile. In the past, the aluminum table sometimes hindered marble workers while processing large blocks, but not anymore.

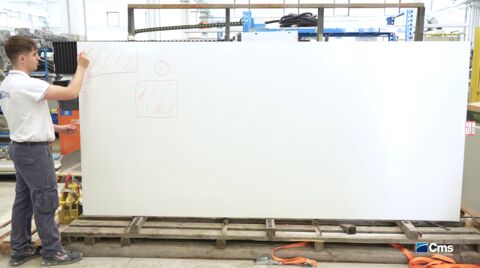

Young talents in stone machining are being trained using CMS Stone Technology machines!

For the past three years, the Staatliche Berufsschule institute in Eichstätt, Germany has been using two CMS Stone Technology machine models, the Brembana G-Rex and the Brembana Milestone, to train its students. These machines are equipped to teach students how to use them at the institute before they move on to a company to gain practical experience and become specialists in the field of stone machining.

The importance of ventilated facades

In construction, a ventilated facade is a complex architectural element that plays several important roles, the key ones being: to protect the building against atmospheric agents, especially water infiltration, improve thermal and acoustic insulation, and allow for new, modern expressive options thanks to the combination of different shapes, material, and colors.

Take the projects directly from your bookshelves!

Imagine a bookshelf full of books where all the knowledge and experience you have accumulated in years of designing are stored. Each individual project, a book that contains the best processes to achieve any result you want.

JetShield: protect your waterjet machine from high-pressure wear

CMS has devised a solution that is both simple and innovative to keep the circuit constantly at cutting pressure even when loading and unloading the material to be cut without compromising the conditions of maximum safety for the operator. JetShield is the “glass”-shaped device installed inside the tank that can house the cutting head’s mixing tube safely, becoming a genuine shield that protects the operator should the cutting head accidentally open.

A passion that unites 3 generations: Artigiani del Marmo

Artigiani del Marmo was founded in 1963 and is now in its third generation. They can produce anything in marble: kitchen tops, jewelry, tables, clocks, furniture accessories, and unique, sophisticated items. They also outfit bathrooms on cruise ships in phenomenal numbers. There is nothing in marble that they have not explored, thought about, planned, designed or produced.

A defect in the slab shouldn’t have to ruin your plans!

Your intention is clear: make the most of each slab and produce as many pieces as possible. The presence of defects, however, ruins your plan. It looks like there is no way out: either wasting a lot of time or generating more scraps. However, an alternative solution does exist: in CMS software, with the aid of photographic detection and advanced defect control functions, nesting around the defects is easier. The result? As much of your slab as possible will be used and scraps reduced to a minimum.

Connected machines are the present, not the future!

Mistral Optical is a company producing, on average, 50,000 pairs of glasses a month. It is located in Quero Vas in the region of Belluno, global center for eyewear. Working on a pair of glasses is a complex operation that needs to find the perfect balance between expert manpower and automated work done by machines. There are about 30 intermediate stages. Knowing exactly at which stage a product can be found in the various processes, at any given time, is the turning point in the entire production chain; representing real added value in the service offered to one’s clients. Precisely with this in mind, the company decided to connect the numerous CMS machines together, from the latest additions to older versions.

Downtimes, what a disaster!

Anyone looking to produce efficiently resents downtimes. Which is why it is understandable that someone would not want to cut a sheet with a bridge cutter and then move the piece to a machining center. Movements, handling, unproductive time.... we need an alternative solution! There is an alternative solution: the flexible CMS brembana formax router, complete with a double worktable, powerful electro-spindle, and suction cup manipulator..

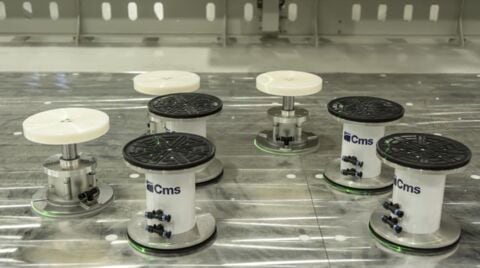

If you save minutes, you produce more.

Positioning the suction cups can be a boring, costly exercise, both in terms of the number of staff used and time spent. Spending too much time at this stage of the process means detracting time from production and, as a result, reduces your earnings. Is there some way to speed up the suction cup positioning process? CMS proposes two highly effective systems.

A good start is essential

I want to obtain maximum productivity as cheap as possible, where do I begin? From the start: an easy positioning of reference pins! In order to make repeated positionings (an easy start point for frequent use that makes it easy to carry out complex projects) the fastest system is definitely the simple insertion of a tip in a hole.

Let’s reduce downtimes!

Nowadays, stone fabricators are looking to reduce downtimes caused by piece loading and unloading. Their main aim is to maximize the productivity of their machine. Our answer is the CMS brembana easyline twin.

Welcome to the world of CMS Customer Service!

Welcome to the world of CMS Customer Service! At your service, to satisfy your demands. With all of CMS’ expertise! Always and everywhere.

Drilling delicate materials? The solution already exists!

Delicate materials run a high risk of breaking when being waterjet drilled under high pressure. CMS...

Claudio Claudi and Cms brembana venkon: craftsmanship at the helm!

An artisan who loves his work, the will to experiment, the desire the go beyond the limits, and a...

Tired of battling with sludge?

In waterjet cutting technology, removing used abrasive, deposited in the tank, is often a tiresome...

Do you work with blocks of stone? This is the solution for you!

If you work in the building products industry, or in the artistic or funeral art sector, CMS has...

Convert a machining center into a Bridge Saw? You can with Cms Stone Technology!

How can I convert a machining center into a bridge saw when the need arises? Cms Stone Technology...

We never stop growing!

Investments at Cms never stop: we have developed a new production area! The production center at...

Cms brembana smartline: with its foot on the accelerator when machining stone!

Cms brembana smartline is a machine for those clients who enjoy the fast lane. The axes' kinematics...