SCM

Via Emilia 77, Rimini (RN)

Italy

We are pleased to offer you a preview of the brand new numerically controlled morbidelli cx220, cx210 and ux200d, drilling centres. These new machines are set to revolutionise the world of drilling. At our Rimini-based Technology Center you can enjoy a full programme devoted to training and live demonstrations. All SCM technologies will be showcased during these few days.

On the 19th and morning of the 20th, demonstrations and presentations can also be organised for customers.

Absolute quality and superior precision, combined with unbeatable productivity and ease of use. These are the strengths of the new range of numerically controlled drilling solutions that SCM, the world's leading producer of secondary woodworking technologies, will present at the “Drilling Is No Longer Boring” event at its Rimini Headquarters’ Technology Center.

The event is an opportunity to discover first-hand the new generation of the morbidelli cx220 and cx210 machines, the world-leading compact CN drilling solutions, and the new morbidelli ux200d, a more complete and flexible CN drilling solution, all offered in an effort to meet the growing needs for customised and integrated production, that is, granting producers the possibility of satisfying any given customer’s special requirements without giving up on the benefits of industrial production.

Every detail in these machines has been designed with meticulous care in order to allow all the required machining operations to be performed with high efficiency, top quality and advanced technology.

“The new morbidelli CN drilling solutions,” says Bruno Di Napoli, SCM Machining Centres BU Manager, “are the result of a comprehensive analysis of market requests, of research and development work, of the Group's extensive know-how acquired over the years, and of the extraordinary teamwork of numerous SCM designers, technicians and specialists."

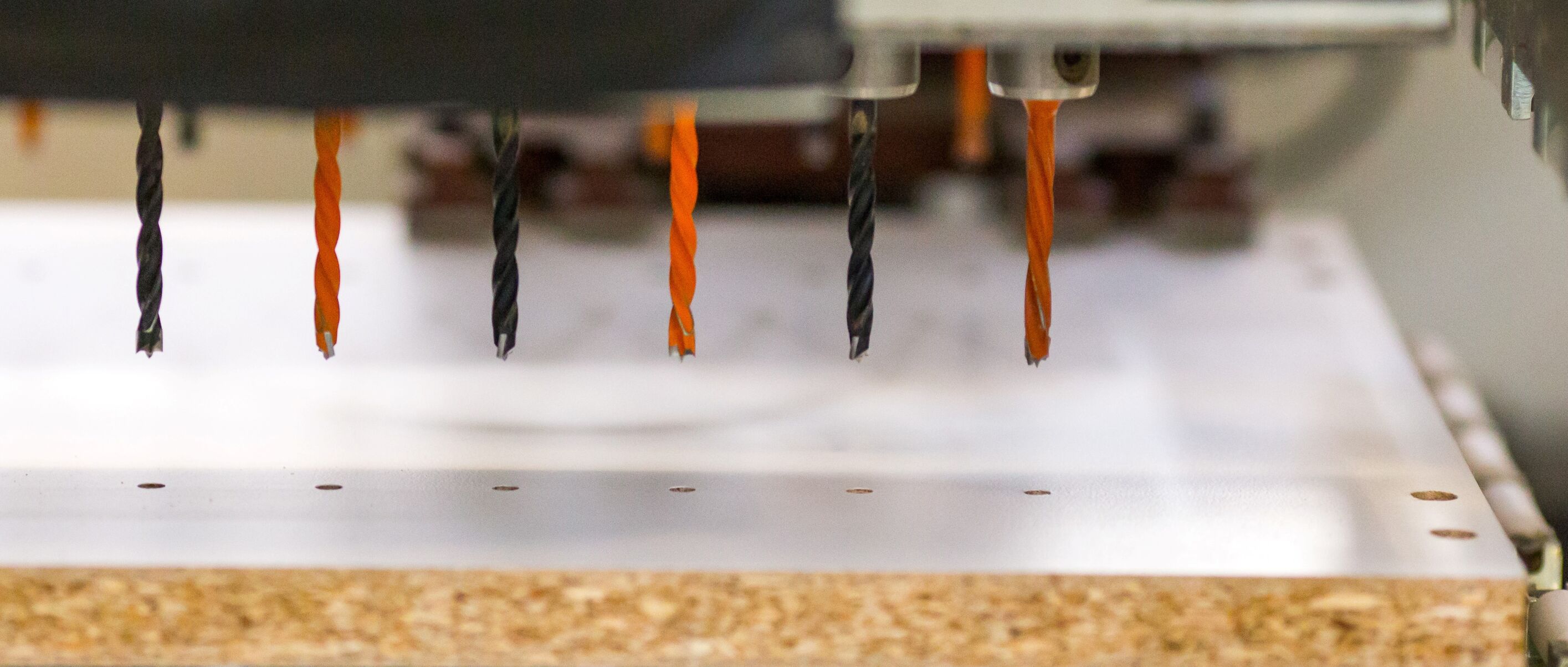

The new generation of CN drilling models cx220 and cx210 adds some significant innovations to the compact and fast morbidelli cx series, already an ideal solution for batch-1 machining.

The new compact drilling heads, with their new design, will help you achieve hitherto undreamt of high levels of performance and efficiency.

The worktable lets you drill delicate surfaces with superior finishing results, while the new profiling hold-down grippers allow you to machine panels even on the inside of the gripper area, while cutting down cycle times and optimising workpiece changes.

Other significant innovations are the new panel return systems with automatic unloading and the possibility of having new customised spindles for customised machining.

The SCM drilling revolution is in clear evidence in the new generation of morbidelli ux machines, with their new exclusive functions offered in the entire series, and in the now-to-be-launched morbidelli ux200d machine with its greater performance machining both small and large panels.

A noteworthy feature in the morbidelli ux200d is the new exclusive broaching system with dual variable-axis broaches that can be adjusted according to the distance between holes. A solution that makes this model even more versatile and efficient for drilling, routing and sawing processes. Among the features available in the entire series are the automatic tool change magazines for both the upper and lower spindles, used for simultaneous machining of opposite sides of panels, and the new Clamex spindles for customised joints.

Other advantages are offered by the highly advanced computer software controlling the drilling cycles and the ability to automatically load panels of any size.

Highly versatile, morbidelli ux200d can operate as a stand-alone machine or as an integrated part of a production line, with various types of workpiece conveyors and loading-unloading systems.

Not just drilling. During the "Drilling Is No Longer Boring” event, SCM's advanced and multimedia Technology Center will showcase a large part of its wide and full range of secondary woodworking solutions – the most complete range in the industry. Notable among machines for solid-wood processing are the accord 42 fx, a machining centre with a new spindle head consisting of 2 independent drilling units (3+5 axes), and the balestrini power, the ultra-versatile and super compact series of machining centres.

Also on view is the wide range of SCM edge-banding machines, from the olympic models to the stefani kd and md solutions, featuring the new AirFusion+ device, which can perform the hot-air/zero glue line application with higher productivity (10% over the earlier model) and cut start-up times by 50%, and the flexible SGP glue pot for a smart glue dosage that ensures perfect edge-banding quality.

Standing out among the beam saws are the gabbiani g 2 115 and gabbiani gt 2 130, which perfectly combine extreme precision with reduced production times thanks to their adjustable axis carriages (HI-TRONIC); automatically aligned blades-engravers (SAW-SET); adjustable axis presses for soft materials; and modular systems for a variety of cuts (Flexcut).

There will be room left also for dmc euro system, the flexible and fully modular sanding machine which may be fitted with all the machining tools that the operator might need, including a cross belt and a superfinishing orbital pad, to reach the highest levels of "High-Gloss" finishing.

And of course there will also be the durable minimax me 35 tr, the edge-bander winner of the Xylexpo Innovation Awards 2018 – for its innovative combined joiner-rounder unit.