MéO

Tecnologias para fechaduras

A new plant with state of the art solutions for doors and windows

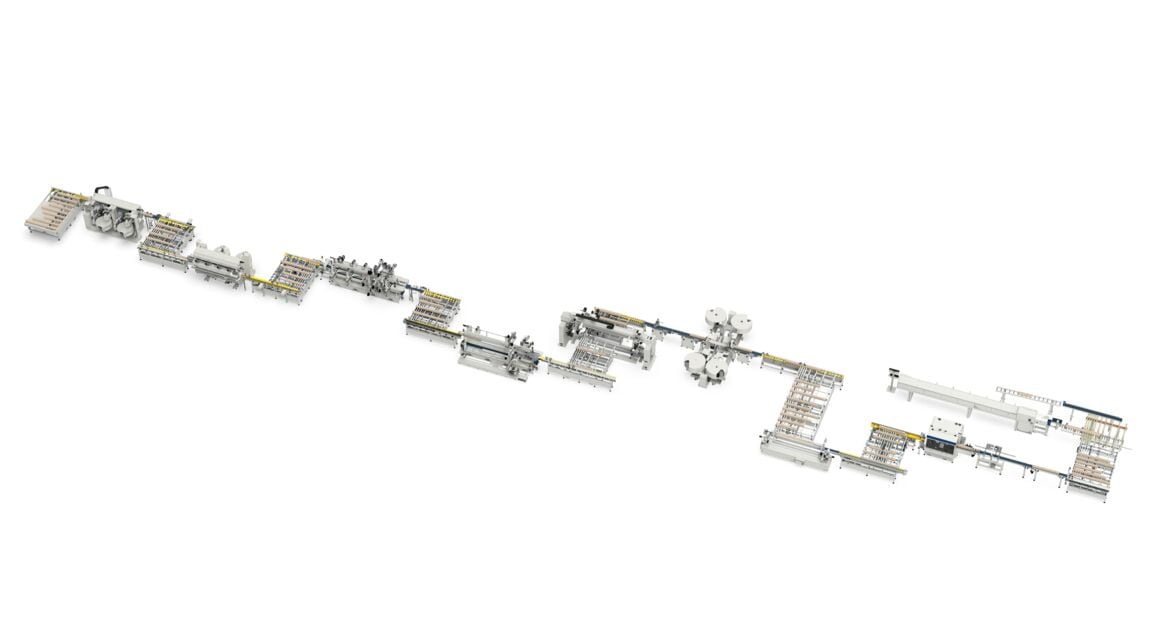

MéO has modernised the whole production process with the inauguration of the new Cugand plant (department 85 – Vendée), which has a new SCM line for doors and window frames. This investment of over 3 million euro has resulted in excellent results in terms of highly flexible productivity and volumes.

After 16 months of work and more than 28 million euro in investments the new plant of the specialist and market leader in wood-aluminium doors and windows is now operational. Inaugurated in 2014 it includes a 25,000 sqm plant for the production of front doors, sliding doors and windows, windows, shaped doors and windows, glass doors and continuous facades. High level technological solutions have been installed, such as the SCM door and window frame line, that fully replaces the previous industrial setup.

“The new production site has been fitted only with new machines, a new production process and a new computer system developed in-house by MéO, inspired from the knowhow of the parent Liébot group”, explains Antoine Soulard, MC France’s industrial manager.

The beating heart of the factory is the SCM production line, which has been fully custom designed. “After a series of tests carried out in Italy, and the shipment to the MéO site, the line began producing in September 2013, with an installation period of 3 months”, explains Claudio Cristalli, SCM product manager in France.

Optimisation of the materials

At the line outfeed the second operator performs a quality control on the machined elements, checking their length and rejecting any with defects.

The elements that pass the quality check are treated with IFH primer (only the pine) before reaching the finishing line.

This is followed by the assembly, the glass is glued and the aluminium coating is positioned.

All the machined elements are placed on a pallet and stored in a closed storehouse heated with wooden shavings from the machining operations.

The boiler is used for the heating system and for the drying and finishing system. An ecological solution to optimise the raw material: wood!

Source et crédit photos: BOIS MAG

MéO (France)

Doors & windows manufacturer

www.fenetremeo.com

Preencha este formulário para receber mais informações