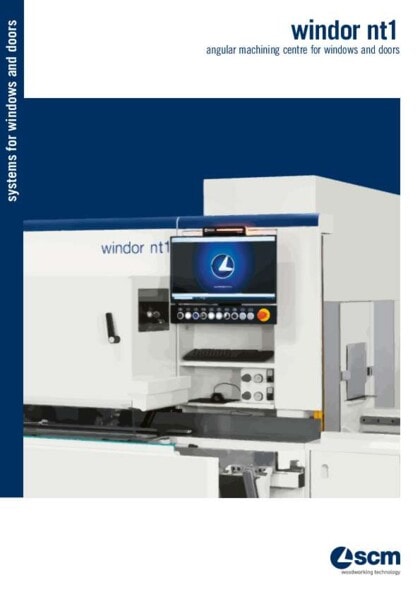

windor nt1

(512) 931-1962

Angular machining centre for windows and doors manufacturing.

It is possible to perform all of the essential operations of end-cutting, tenoning, drilling-routing and profiling regardless of construction concept, joint and section type.

The machine structure is completely enclosed in order to reduce noise to a minimum and ensure maximum safety for the operator.

BEST-IN-CLASS PERFORMANCE

Production of all types of tenon, straight and angled.

Excellent precision during the processing thanks to the solid structure of the tenoning carriage.

INCREASED PRODUCTIVITY

No limits to profile execution: to meet all the profiling requirements, the machine can be fitted with two 50x320 mm spindles.

EASE OF USE

SCM innovative touch screen console eye-M allows a comfortable easy navigation of the machine managing software, Next, with a simple and intuitive interface.

| windor nt1 | ||||

| Min. - max. work-piece length | mm | 200 - 3000 (200 - 3800 opt.) | ||

| Min. - max. work-piece width | mm | 40 - 200 | ||

| Min. - max. work-piece thickness | mm | 40 - 140 | ||

| Maximum tenon angle | ± 60° | |||

| Feed speed of tenoning carriage | m/min | 0 ÷ 12 | ||

| Feed speed in profiling | m/min | 6 (4 ÷ 10 opt.) | ||

| Worktable height in tenoning | mm | 990 | ||

| Worktable height in profiling | mm | 870 | ||

Vul het online formulier in om contact op te nemen met een productadviseur