Cms kreator: Making Additive Real

2021. jún. 7.Large Format Additive Manufacturing and Milling by Cms!

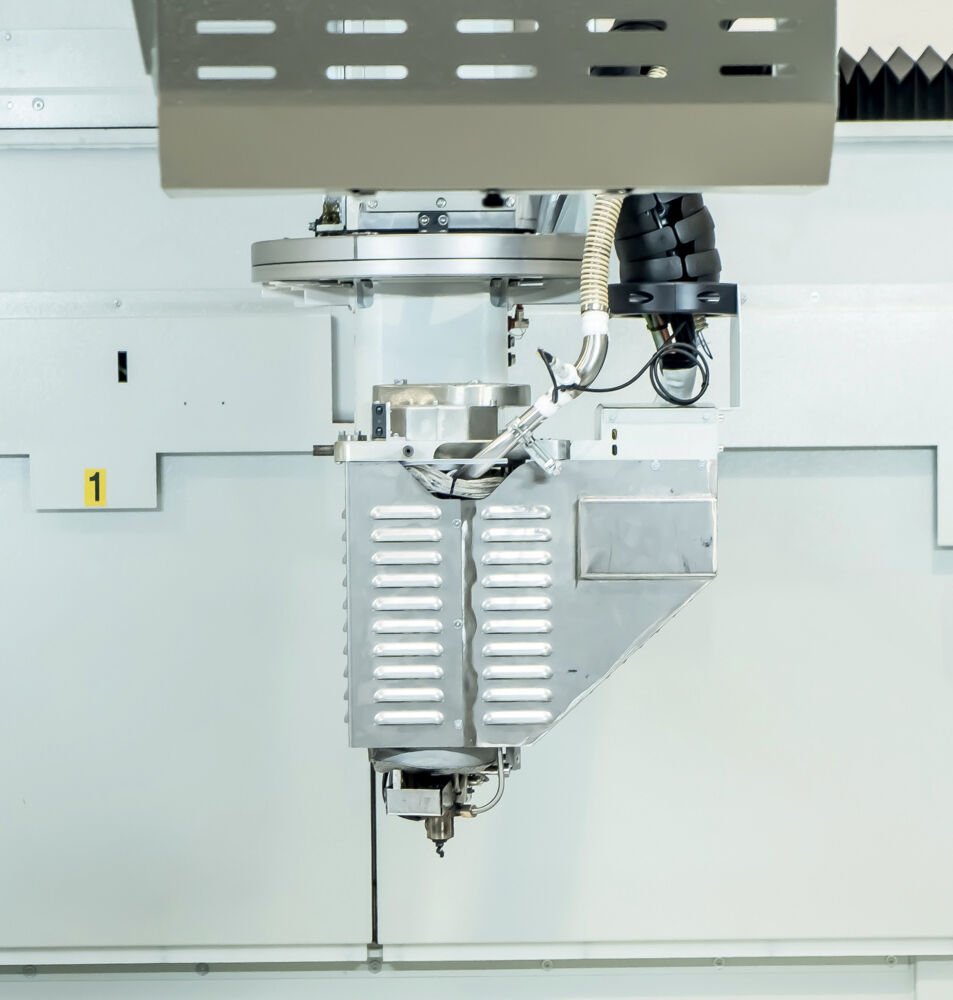

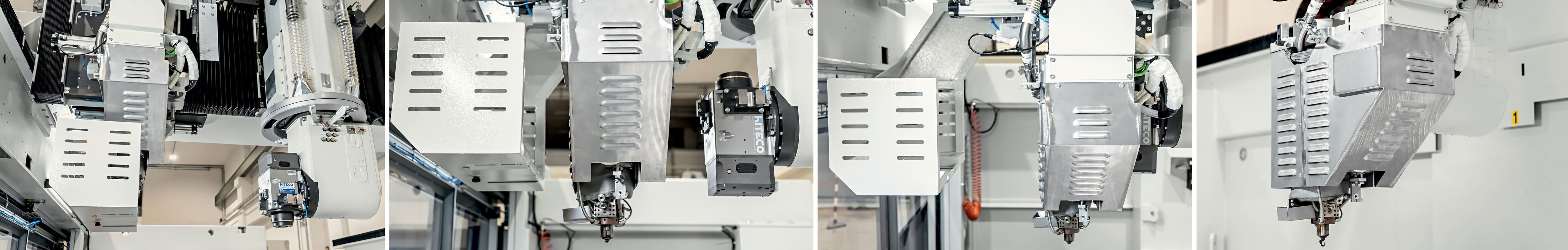

CMS kreator is a CMS machining center also coupled with an extruder, to get the Screw Extrusion Additive Manufacturing, together with the standard 5-axis milling, developed in cooperation with Fraunhofer Institute.

STRONG REASONS WHY

- Unique solution, designed to integrate completely a machine tool and a large format 3D printer.

- Raw material cost saving factor compared to current manufacturing technologies: more than 5.

- Up to 5 times less material than competitors, to print the same part.

- Fewer subparts, less manufacturing time, less cost than large sized FDM.

HOW DOES IT WORKS?

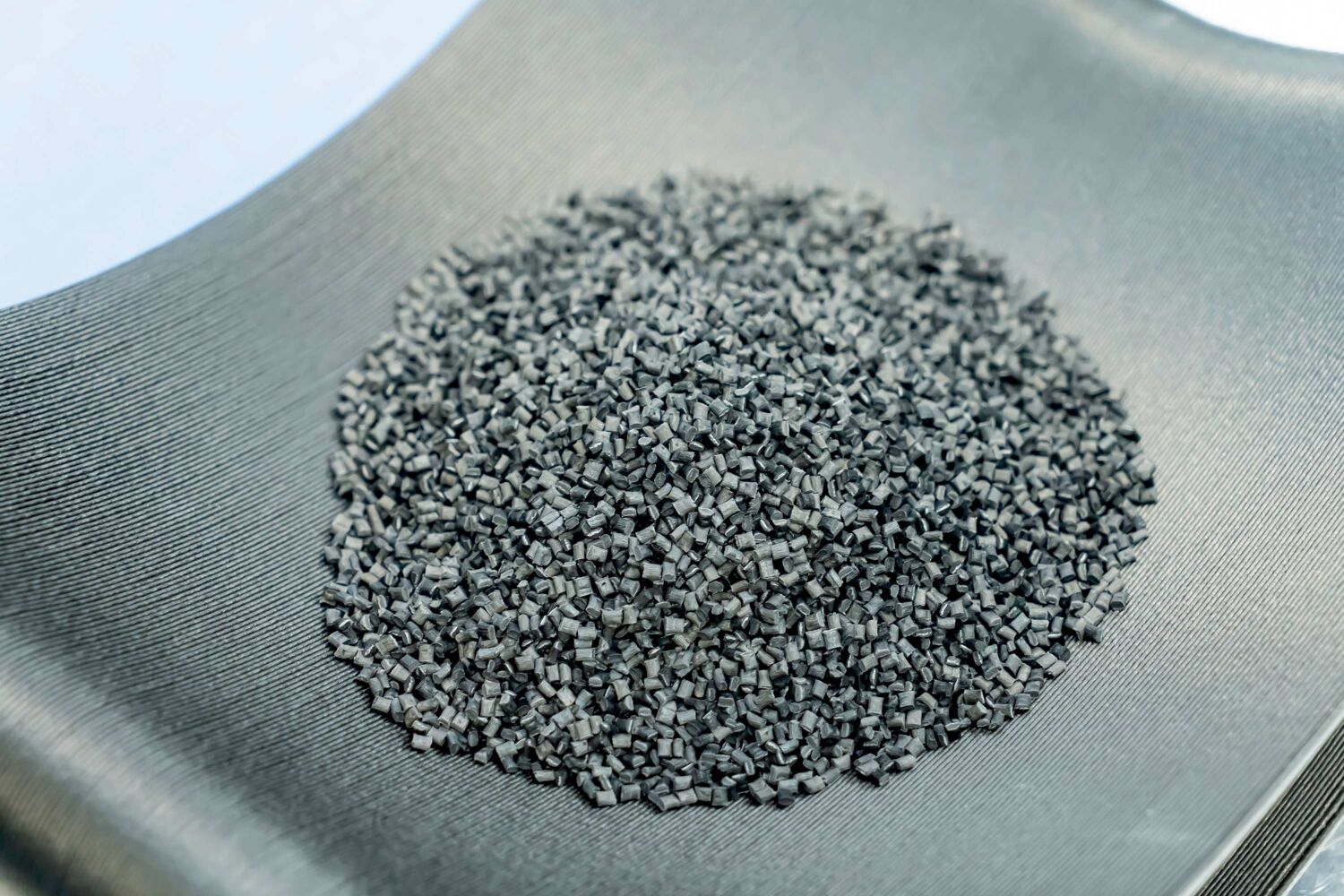

The Additive Manufacturing technology adopted is Screw Extrusion Additive Manufacturing (SEAM). Thermoplastic polymer, in granulated form is the material used. The polymer is almost always reinforced (discontinuous fibres of carbon or glass) and the reinforcement is inside the granules.

The extrusion is done by a single screw extruder that melts the granules. The extruder is moved by the tool machine's axes. The melted polymer exiting the extruder is deposited in layers that plasticize and form a single piece.

COMMON AND NOT EXPENSIVE MATERIALS FOR 3D PRINTING

Commercial thermoplastic granulates is used for injection molding. We started with polyamide (nylon), reinforced with carbon fiber (PA6/CF40, PA6/CF30, PA6/CF15). The extruder has been tested by R&D also with PP, PESU, PEI, PET, ABS and others, reinforced with carbon fibers or glass.

But our policy is to prioritize the application: if a material works well for a specific application, why change?

EXTRUSION DESIGNED FOR HIGH QUALITY 3D PRINTED MATERIAL

The extruder and the extrusion process have been designed to get high quality 3D printed material. It’s a classic extrusion process: the melting is obtained by friction and resistances are used just as a thermal support.

High quality 3D printed material means “vacuum integrity”. Since the first stages of the project the vacuum and the absence of voids have been tested. Devices helping layers stay attached to each other (e.g. rollers) are unnecessary.

Cms kreator ares can be used to manufacture tooling for composite (machining jigs, lamination masters) or other parts.