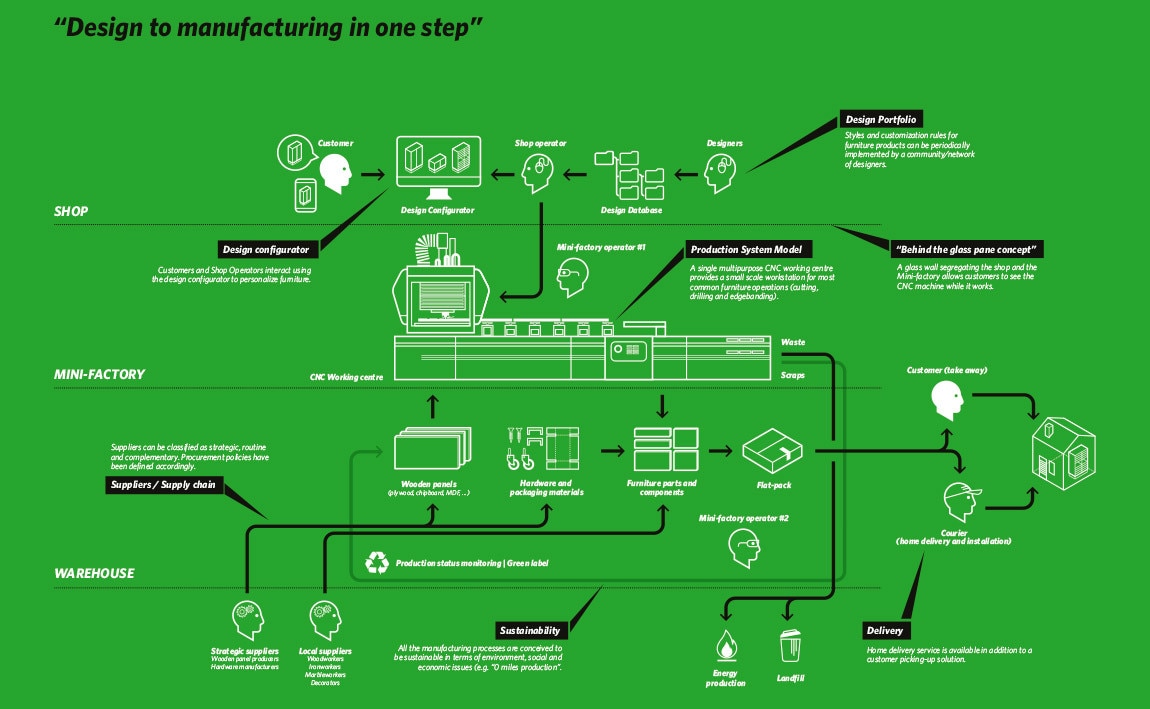

The “Close to Customer" project is based on the Furniture on Demand concept. A “mini-factory on display”, in a shopping centre, where the customer can use a simple interface to “draw” the piece of furniture he or she would like to buy - customizing its shape, size, colour, etc. - which is then immediately produced, on-the-spot, and delivered.

The first prototype of the project is the “mini-factory” installed in the Shopping Centre in Brianza, Paderno Dugnano (Milan province), which opens a captivating window onto what could be the future of furniture production. The project cuts associated transport costs and pollution: the ultimate in “Mass customization”.

Scm Group unveiled the first prototype at IDEA Innovation Design Expo Area that took place at Fiera di Bergamo from 12 to 15 April 2016.

Design, production and delivery, all in one step: fully automated production, but at the same time an expression of something unique and extreme customization, which puts the customer at the heart of the process, so he becomes his own furniture designer.

It will be a Scm machining centre that produces “live on demand”, in a fully automated way, the furniture that will be configured – starting from a ready-made portfolio of products - directly by customers, who will be able to immediately “take home” an object made with an industrial process but which is the only one of its kind in the world.

The “Close to Customer” project, financed by the European Community, is the result of more than three years of research involving not just Scm Group, but another 10 European partners, including companies that are leaders in their sectors, and universities (http://www.mckn.eu/projects/CTC/).

It was conceived with the aim of supporting the furniture industry, providing real tools for responding to changes in the world market, by developing innovative methods and technologies for flexible and local production of sustainable and customised products, which are increasingly close to the customer in terms of the features offered, the production location, delivery times and price.

![]()

The woodworking machine represents the “heart” of the mini-factory. It is the working centre machine able to integrate in a single machine all the most important functionalities required for wood panel working. The CTC woodworking system will be finally integrated with the other software develop in this project.

![]()

Customisation is at the heart of the CTC project. Through a tablet app, the customer defines the structure and features of the chosen furniture item. The prototype is then directly sent to the mini-factory in the shopping centre where the piece is immediately produced.

![]()

The supply chain and production system model are meant to lay the basis for a customizable and flexible production in order to develop a standardized mini-factory business model that can be easily and quickly instantiated in local green factories, and whose processes and machines can be simply implemented in according with the CTC handbook.

![]()

The CTC Green label envisages the computation of a life-cycle assessment for products considered by the instantiation of the mini-factory so to

grant and demonstrate customers the environmental sustainability of this new business model.

For more information:

SCM Group - Antonio Caressa antonio.caressa@scmgroup.com

SUPSI - Andrea Barni andrea.barni@supsi.ch