Scm Group has been the protagonist of the 25th edition of Xylexpo 2016 (24-28 May, Milan) with over 40 machines on display in 3,000 sqm exhibition space, covering all sectors of woodworking industry. Discover more:

SCM Group was a major participant in the 25th Xylexpo fair, invigorated by its growing success and presenting the most extensive and innovative line of technological solutions for the woodworking industry.

“We have chosen to take part in Xylexpo to give a strong message to the market and to continue supporting the development of the Italian manufacturing technology industry, a globally recognised excellence and the reference point for wood manufacturing. For over 60 years we have supplied the widest and most innovative range of solutions and advanced systems, designed for those working with wood and other materials, such as plastic and composite materials and we want to maintain our guiding role in the sector”. Luigi De Vito, Scm Group Machine Division Manager.

The Group continues its brilliant growth. "We started 2016 with a double-digit growth in orders and sales, with a trend of cash-flow generation growth," says Luigi De Vito, Director of the SCM Group Woodworking Machinery Division. “Record results, with 2015 closing with over 500 million Euro in sales, a 10% growth compared to 2014. An excellent achievement, driven by our Woodworking Division, which exceeded 380 million Euro in sales, a 23% growth, a brilliant performance that makes us the second-ranked player in the industry."

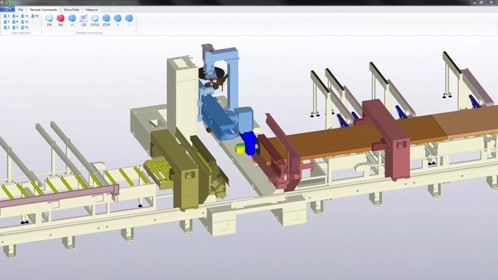

The group revolutionises the way machines are displayed at the fair and adds alongside the technological systems around the stand an innovative multimedia system. Using two large videowalls (6 x 3.4 metres) SCM shows visitors a virtual rendering of some of its technologies.

Using 3D animation, filmed at 6K high definition, the machines are reproduced in their real-life dimensions with stunning detail, offering the visitor new interaction possibilities. Using an iPad, for example, the visitor can "enter" these machines and follow from up close every single detail of the woodworking process.

A groundbreaking industrial innovation that is a huge technological step forward: the possibility of machine virtualisation means, on the one hand, being able to drastically reduce energy consumption and the environmental impact of product movement, and, on the other, being able to offer customers a multimedia tool with unlimited potential which in some respects can exceed the actual, real-life, experience.

"A company's leadership is measured by its ability to pursue a 360-degree innovation strategy, also in communications. At Xylexpo, we wish to affirm this approach, presenting a new machine virtualisation system, the result of an extraordinary work and investment by SCM and which will allow industry operators to better appreciate the wide range of technological solutions the Group is offering," says Gian Luca Fariselli, the SCM Group Corporate Communications Director.

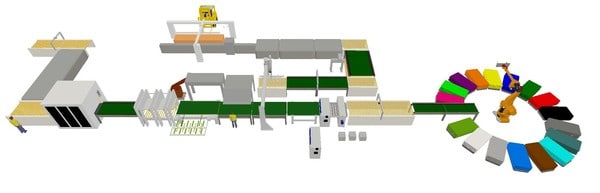

At Xylexpo, SCM presents in a large exhibition space of 3,000 sq. m. its "EASY & RESPONSIVE" production solutions for Industry 4.0 scenarios: integrated solutions and modular cell systems that offer intelligent innovations and combine sustainable investment with an ability to reconfigure production flows in order to meet consumers' requests for a wider product variety and customisation.

Specifically, the following will be on display: Integrated cell systems, easy to programme and reconfigure and with advanced storage systems that take up little space and consume less material, less energy and less investments; automated cells with rapid set-up times and ever more user-friendly interfaces, even for unskilled personnel.

They are, in a word, production systems that are agile, responsive, ready for changes and able to render "mass customization” competitive.

All prizes awarded:

What guides SCM Group communications is the "Strong Reasons Why" concept.

The idea behind it is to focus on the Group's strong values, which translate into tangible benefits for operators, and to demonstrate the company's ability to offer industry professionals an extremely wide and complete range of woodworking products and solutions.

At Xylexpo, Scm will present the latest developments of the group and its brands in a large exhibition space of over 2600 square metres. These will include integrated solutions and modular cell systems, which reflect the intelligent innovation approach, a direct interpretation of the “Smart Manufacturing". In particular we will present integrated production processes for panel and solid wood machining, all “intelligently flexible”, and capable of combining different levels of profitability/productivity, utmost customisation and extremely easy reconfiguration possibilities. The aim is to provide the industry with solutions for productions with shorter time-to-market, to increase competitiveness on the markets and at the same time allow for a greater level of specialisation.

The technologies presented by the Scm Group are therefore designed to optimize and facilitate the creativity of small woodworking workshops and large industries, supporting them in the process towards “mass customization”.

The software, a centrally important aspect to the “Smart Manufacturing” logic, will be one of the strong points at Xylexpo. Scm Group will bring to the show all its know-how and a suite of state of the art, and continuously evolving, softwares, developed to guarantee the complete use of the machines’ functions and achieve a more flexible and customised production and industrial process.

At the show the group will present its unique scalable cell systems. This range of solutions can meet the production demands of an industry that is increasingly looking for greater flexibility, easy integration and profitability. Many of the technological developments of the group will be found in the integrated and modular production processes. This choice reflects the extensive and comprehensive competence of the Scm Group’s specialists in all the application fields of the sector.

Two integrated cells for machining panels will be on show.

Cell system for high production capacities (up to 1300 pieces per shift) that consists of the following:

Cell system for medium production capacities (up to 1000 pieces per shift), that consists of the following:

The following technological solutions to process solid wood will be on show:

Perfect edge finish and an extremely diversified production within the means of any company; these are the key aspects of the edge banding systems that Stefani and Scm will have on show at Xylexpo.

In particular, the focus will be on the wide range of gluing systems, the new SGP glue tank, Air Fusion technology, and the new integrated PU BOX L pre-melter, found on the whole range of Stefani and Scm Olimpic edge banders.

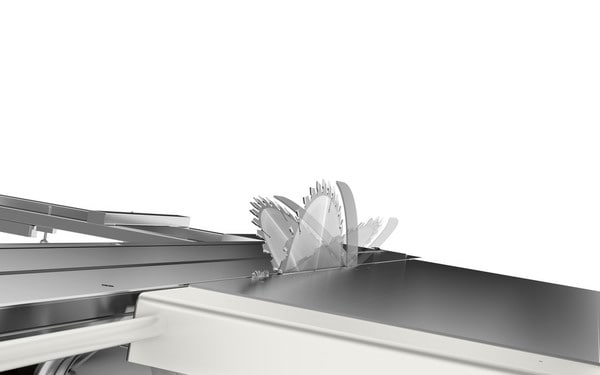

Gabbiani’s presence at the show will focus on the Galaxy 3 110 A beam saw, integrated in the “batch one” panel sizing cell and enriched with the new electronic carriage that ensures extremely competitive performance levels.

The beam saw will be fitted with the “Flexcut/1S” single clamp unit”, the ideal combination to achieve utmost flexibility and increase performance, now also available with the wheeled table for delicate materials.

DMC will take part in the show with the range of System flexible wide belt sanders. This modular system features unique new devices that allow for prestigious finishes found in hand-made pieces such as the saw cut, woodworm, structured and wave-effect, as well as the most varied brushing and rustication effects.

Sergiani Las 230 automatic continuous cycle press for the production of hollow core and coated doors and pre-finished parquet (2-3 layers).

Superfici, the brand specialised in finishing surfaces, will present state of the art solutions for painting panels, furniture parts and door and window frames, with a specific focus on flexible applications and using the most advanced painting cycles.

Scm will bring to Xylexpo the exclusive L'invincibile range. This has always been the classical machines reference point for small to mid-sized companies and for larger saw mills that produce non-standard items or with prototyping departments, The “L’invincibile Six” circular saw with +-46° blade tilting, the pinnacle of the design and technological excellence of the group, will also be on show.

The new machining centre Scm Accord 50 fx, presented for the first time on the Italian market, will be display on specific applications not only for wood, but also plastic and advanced materials. This 5-axis machining centre with fixed worktable and mobile gantry can perform drilling of work pieces up to 500 mm in heights, using tools of big dimensions.

The Bergamo-based company will bring to the show 4 work centres, which represent the ideal solutions for the most demanding sectors that have to marry versatility, precision, high-volume productions and a complete automation of the process. These work centres are the result of C.M.S.’s vast and consolidated experience at the service of the woodworking industry.

CMS Wood Technology:

ANTARES, the 5 interpolated axes work centre provides exceptional movement dynamics to achieve high productivity levels and excellent finish quality. The single block structure guarantees long-term stiffness and precision.

MONOFAST, the exclusive solution for the automated production of complex parts and the winning formula for unique machining operations such as rifle stocks, cheekpieces, glasses and small-sized objects.

CMS Balestrini:

CUBE, the 5-axes work centre with two independent units, in practical terms a machine and a robot at the same time. It features two machining heads that, thanks to the machine’s innovative geometry, work, to all intents and purposes, as two independent 5—axes work centres, performing all the machining operations on the piece very quickly.

POWER, the innovative range of gantry type work centres, which is extremely flexible and able to meet the numerous and ever-increasing demands of the woodworking industry. It can be configured with different specific solutions to achieve maximum productivity levels. Its compact dimension improves bench handling during the changes in machining without sacrificing power.