With both abrasive and pure waterjet technology, the compact version of CMS tecnocut smartline is designed to meet the needs of rapid prototyping and small batch production. This solution is particularly suitable for research centers, prototyping laboratories, small mechanical workshops, and companies that fabricate with metals, composites, plastics and rubber.

From June 12 to 14, our Zogno (BG) facility hosted the CMS Open House: three days of innovation, live demos, technical insights, and meetings with customers and partners.

When it comes to industrial cutting, choosing the right technology makes all the difference. Waterjet cutting is an extremely versatile solution that allows you to process any material, from metals to natural stone, plastics, and even food products.

In the world of waterjet cutting, the efficiency and reliability of pressure intensifiers play a fundamental role in both quality and operating costs. Traditionally, these systems rely on conventional hydraulic pumps, but with the introduction of hybrid technology, the industry has taken a significant step forward in terms of performance, sustainability, and energy efficiency.

Waterjet cutting technology, thanks to its versatility and ease of use, is constantly growing as a tool for optimizing production. CMS waterjet solutions are ideal for cutting a wide range of materials, including metals, composites, foams, panel insulations, ceramics, glass, and high-thickness materials. They represent the perfect technological choice for those who need to meet diverse production requirements.

2024 was a year of significant progress for CMS Metal Technology, marked by the introduction of the pressure intensifier tecnocut e-pump during last May’s Open House.

The versatility and potential of waterjet cutting technology are combined with the new DDX EasyJet, the complete CMS suite that brings together several applications in one software to program machining processes quickly and easily.

Thermally insulating a truck body can make all the difference, especially when transporting goods that are sensitive to temperature changes or getting fresh, well-preserved food to our tables. Isothermal walls are the structural basis of the insulated body, and bring significant benefits because they:

The versatility of waterjet cutting technology enables a wide range of materials to be processed in various sectors, such as: construction, thermal and acoustic insulation, automotive, aerospace, railway, packaging, footwear, sealing.

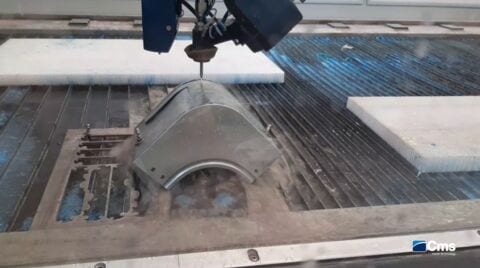

One of the key advantages of waterjet technology is that being an erosive process, there is no relevant physical contact between the cutting process and the part being processed, by making the worktable set up quicker and simpler to operators.

CMS waterjet cutting technology offers tremendous benefits in terms of flexibility and ease of use and is a winning solution in metal alloy, composite and plastic cutting applications. The 5-axis configuration can perform precision mechanical machining, dynamic water jet compensation, and edge caulking for welding.

Last November 16th, we lived unforgettable moments together with some of our clients at the Ferrari Museum in Maranello. Presenting our technologies in such a unique context, rich in the history of the quintessential Italian automotive house, was an exciting experience.

CMS further strengthens its presence in Australia, by formalizing the agreement reached with INNOVYNC. A key player in the world of metal, Innovync becomes the new service and sales provider in Australia for CMS Metal Technolgy.

In the world of pressure intensifiers for waterjet cutting, CMS stands out by offering the market a unique model featuring a parallel-cylinder design. This type of architecture can maintain an output pressure with a constant signal, without the need to install an additional downstream accumulator, a requirement typical of the opposing-cylinder intensifiers on the market.

Waterjet technology is a versatile cutting method that can cut a wide range of objects and materials. As the image above shows, we will discuss here how waterjet technology can be useful in cutting pipes.

We have just got back from Lamiera 2023! It was nice to share our technology for metal processing with all of you who came to visit us. We hope to see you soon!

Mixing water at high pressure with abrasive granite makes cutting hard, very thick materials easy. Used abrasive gathers in the collection tank during this process and should be removed from the outside and disposed of in special bags.

When processing soft materials, like foam and seals, the cost of production is a key factor that requires maximum process efficiency and the ability to deal with high volumes.

CMS has devised a solution that is both simple and innovative to keep the circuit constantly at cutting pressure even when loading and unloading the material to be cut without compromising the conditions of maximum safety for the operator. JetShield is the “glass”-shaped device installed inside the tank that can house the cutting head’s mixing tube safely, becoming a genuine shield that protects the operator should the cutting head accidentally open.

F.lli Sacchi was established at the start of the 1900s, and is a global leader in innovative systems for transport, dosage, storage, packaging and palatalization of loose products in granule and powder form. The company’s uniqueness lies in having invented robotics applied to powder and granules. Since 2015, F.lli Sacchi has chosen CMS as a technological partner in supporting its growth thanks to the quality and reliability of the products in the CMS waterjet range, capable of combining cutting with versatility and flexibility with the simplicity of programming. Sacchi recently opted to add the innovative and unique CMS tecnocut proline waterjet machining center to its range of machines.

Mistral Optical is a company producing, on average, 50,000 pairs of glasses a month. It is located in Quero Vas in the region of Belluno, global center for eyewear. Working on a pair of glasses is a complex operation that needs to find the perfect balance between expert manpower and automated work done by machines. There are about 30 intermediate stages. Knowing exactly at which stage a product can be found in the various processes, at any given time, is the turning point in the entire production chain; representing real added value in the service offered to one’s clients. Precisely with this in mind, the company decided to connect the numerous CMS machines together, from the latest additions to older versions.

Now we can move forward and reach new levels: The combination between the 5-axis JD5 cutting head and the software DDX Easyjet offers an opportunity to expand the cutting capabilities of waterjet machines in the CMS range, by expanding application limits! Due to the intuitive and user friendly programming, by starting with a 3D model, it is now possible to control every processing aspect from the direction of the cutting head to actual head movements, in order to avoid collisions with the piece.

The versatility of the waterjet cutting technology allows you to process a vast range of materials in different industries, such as: construction, refrigeration, automotive, aerospace, railway, packaging, footwear, and sealing.

Welcome to the world of CMS Customer Service! At your service, to satisfy your demands. With all of CMS’ expertise! Always and everywhere.

The PoliMi Motorcycle Factory (PMF), thanks in part to its collaboration with CMS, has achieved a...

With the tecnocut proline, CMS sets new market standards in terms of programming and machine...

In waterjet cutting technology, removing used abrasive, deposited in the tank, is often a tiresome...

Cms Metal Technology expands its technical solutions offered to the market with an exclusive,...

What can Cms Metal Technology do for gyms, swimming pools, interior and exterior playgrounds,...