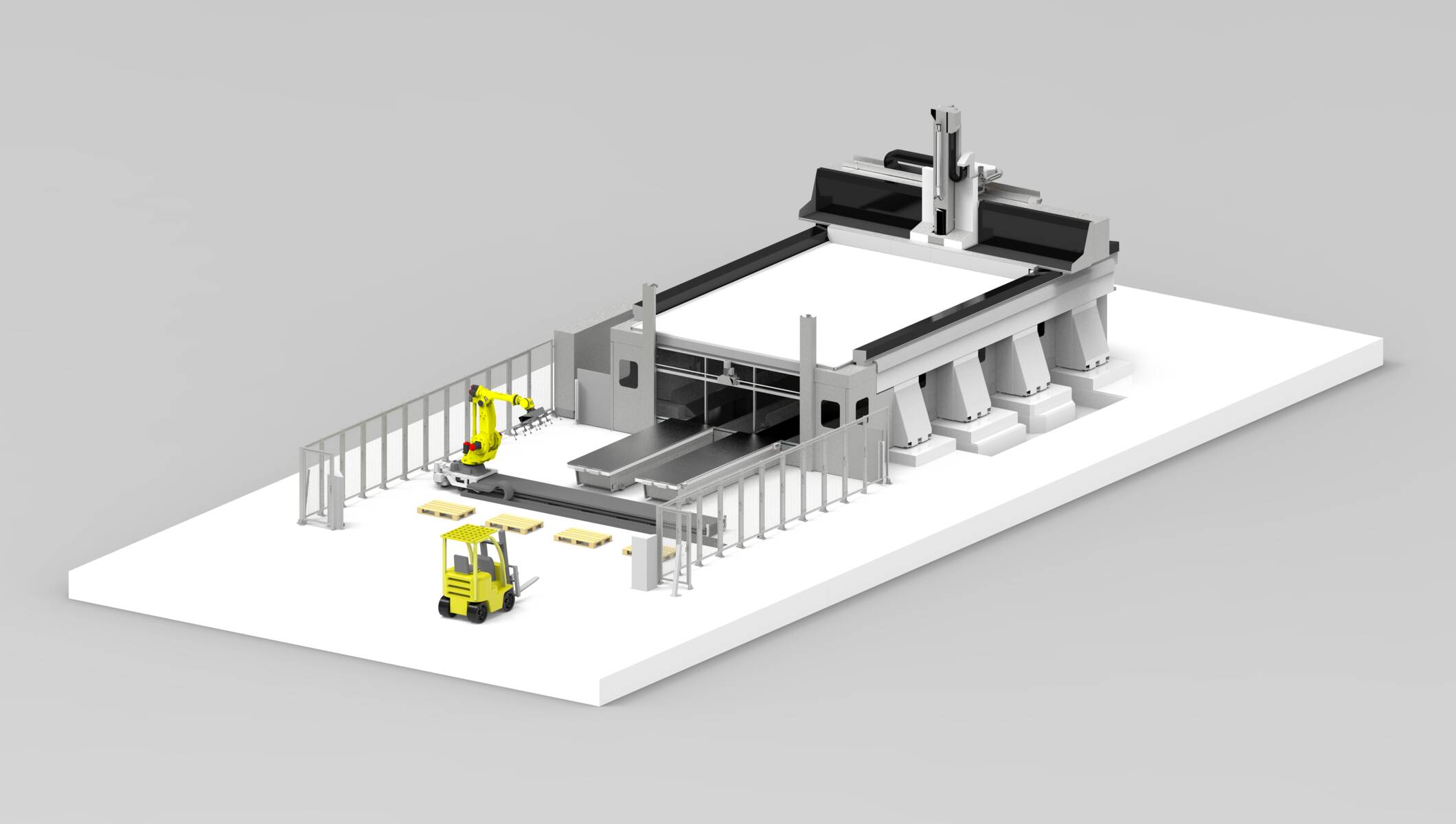

Turn-key automated solutions with a high degree of customization to streamline business production processes, increase productivity and meet the most complex handling needs. The CMS team works to offer customers significant competitive advantages and “Ready to Use” custom solutions, starting with an analysis of the customer's context and targets, which leads to the design of more or less complex automation lines or cells with integrated anthropomorphic robots.

Having CMS as a single reference point means having direct contact and a personalized service.

We study and develop machines, systems and production lines with a tailor-made approach

We create a training plan customized to the customer’s requirements so that it can manage its plant in the best possible way;

We support and follow the customer through the entire after sales management process: on-site or remote technical support for troubleshooting, maintenance, parts and retrofits, and much more.

Key buyer benefits

More accurate production data and less downtime means a short-term return on investment;

Cost reduction. The company is freed from fluctuations in skilled labor availability and has a single qualified reference partner;

Increased productivity: personnel can spend more time on activities that add more value to the company, leaving automation to deal with repetitive processes;

High reliability: limiting manual processes means reducing the risk of errors and increasing reliability.

Flexible automation: introducing robotics and advanced automation allows flexible production management that is capable of responding to unexpected events or coping with fluctuating and changing demand. And all in very short times.

Improved safety: industrial automation can make the production line safer for employees. Robots can be used to handle the more hazardous tasks;

Space optimization: including cells or automated lines in production allows more logical and functional use of the space;

No need to train new personnel: the same HMI can be used to manage both the CNC and robot in the same way. There will therefore be no need for specific programming skills because there is just one operator interface. Robot motion and teach points will be executed from the same operator panel.

Remote monitoring of the entire cell: With a single click, CMS can remotely control the entire cell – meaning machining center, PLC and robot – all via CMS Connect with a VPN connection. No surprises, everything is always under control!

Fill out the online form to be contacted by a salesperson