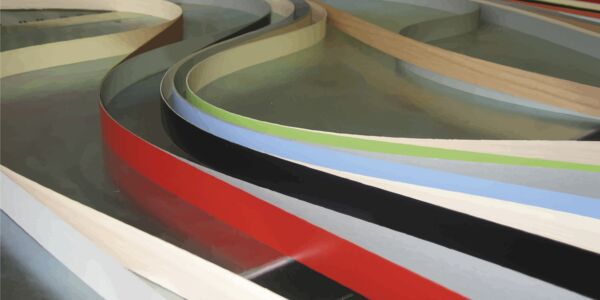

Flexible edgebanding solutions

Stefani Cell for Batch 1 Production | Stefani Cell H | Stefani Cell S | Stefani Cell E | Stefani Rocket for a large volume "Mass Customization" production

Stefani Rocket U | Stefani Rocket H | Stefani Rocket E

The integration into working cells of single-sided edgebanders equipped with automatic set-up operating units and advanced handling systems supported by "intelligent" software allow flexible and efficient machining of panels according to the production variability today's product customisation requires.

The integrated management of machines and automation makes each panel's information available even on mobile devices thanks to the continuous tracking of the pieces managed by the maestro active watch supervision software. Furthermore, it is possible the real-time management of components (parts to be reprocessed), the interfacing with MES production control system (Manufacturing Execution Systems) and ERPs software (Enterprise Resources Planning).

Panel loading and unloading devices, anthropomorphic or Cartesian robots, combined with automatic and integrated warehouses and connection devices to upstream and downstream processes, ensure higher productivity and continuity of the production flow. The effortless and fast management of the roll changeover on the edgebander can take place thanks to the Edge Store Manager. This automatic learning system matches the running program with the right edge by reading a barcode or QRcode.

The new SCM flexible edging systems, cells or edgebanding and square-edgebanding lines, are divided into two ranges: the stefani cell and the stefani rocket.

STEFANI CELL FOR BATCH 1 PRODUCTION

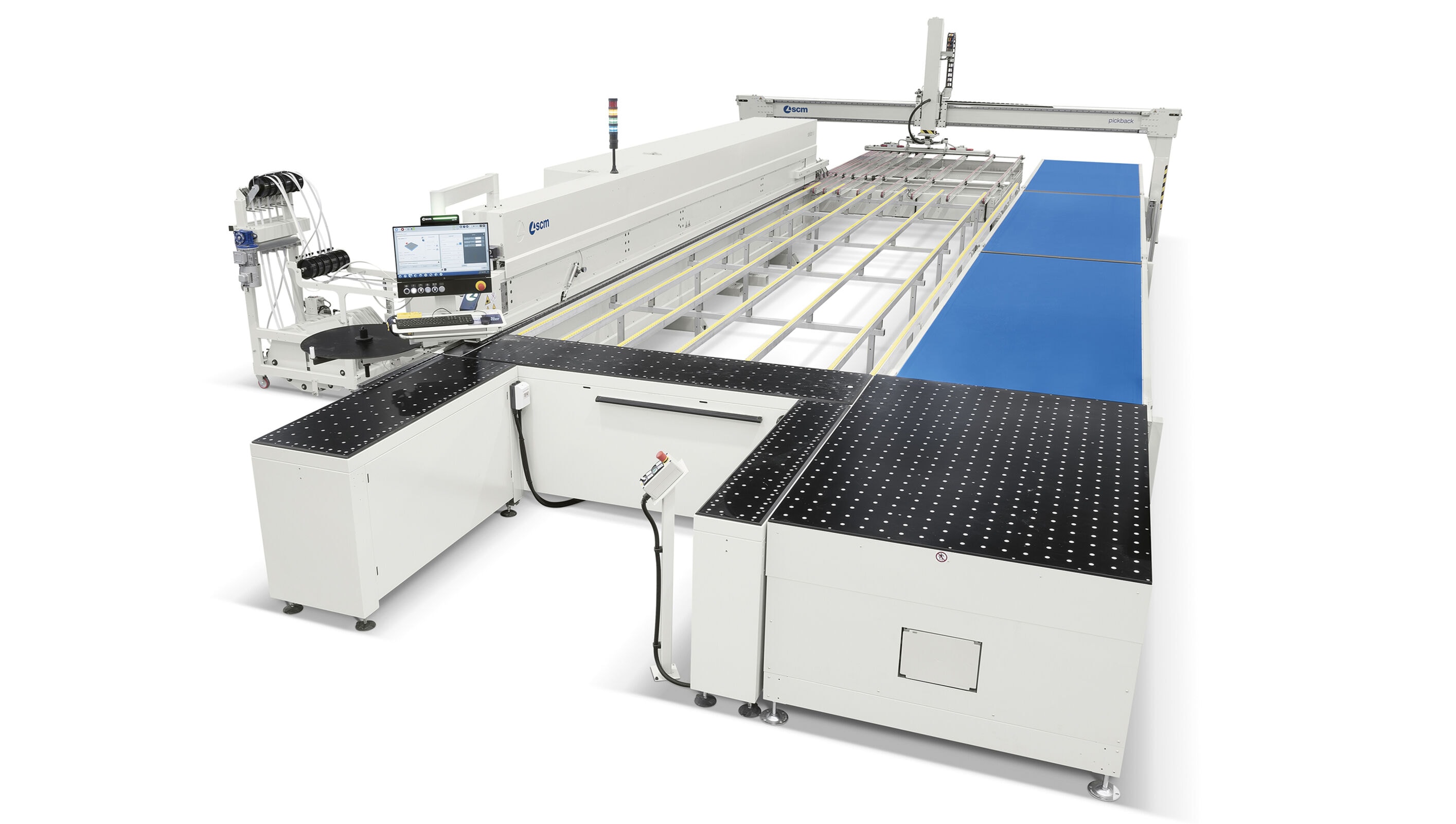

The stefani cell range includes flexible edgebanding cells consisting of a single-side edgebander integrated with devices for the panel return and the automatic loading and unloading of the pieces. The panel handling devices of stefani cell consist of integrated modules that allow creating plants tailored to the various needs of the users for a lean and flexible production process. Intelligent and real-time software management allows a continuous production flow with a single operator for the supervision and the control of the cell with economic and operational advantages.

Edgebanding and square-edgebanding cell equipped with automatic panel inserting systems, designed to guarantee industrial-level production volumes and maximum diversification of the batch one production.

This solution is characterised by:

- Production versatility without downtime

- Immediate and cost-effective production without distinction from the single panel to the average standard stack: without any production downtime when changing the panel size, edge and glueing type.

- Precision and reliability: available with different panel introduction systems, with or without squaring function combined with single-sided edge banding machines.

- Configurability and customisation: modular solutions based on the customer's production process regarding the working units and the handling equipment.

All-In-One square-edgebanding cell with single-operator architecture and squaring function, suitable for companies oriented to medium investments for a semi-intensive production with non-standard sized panels.

This solution is:

- Compact and high-performance: stefani cell S processes panels requiring parallelism/squaring machining (e.g. coming from a beamsaw). Thanks to the innovative semi-automatic introduction system with squaring function, it is possible to process even large panels, lengthwise and crosswise.

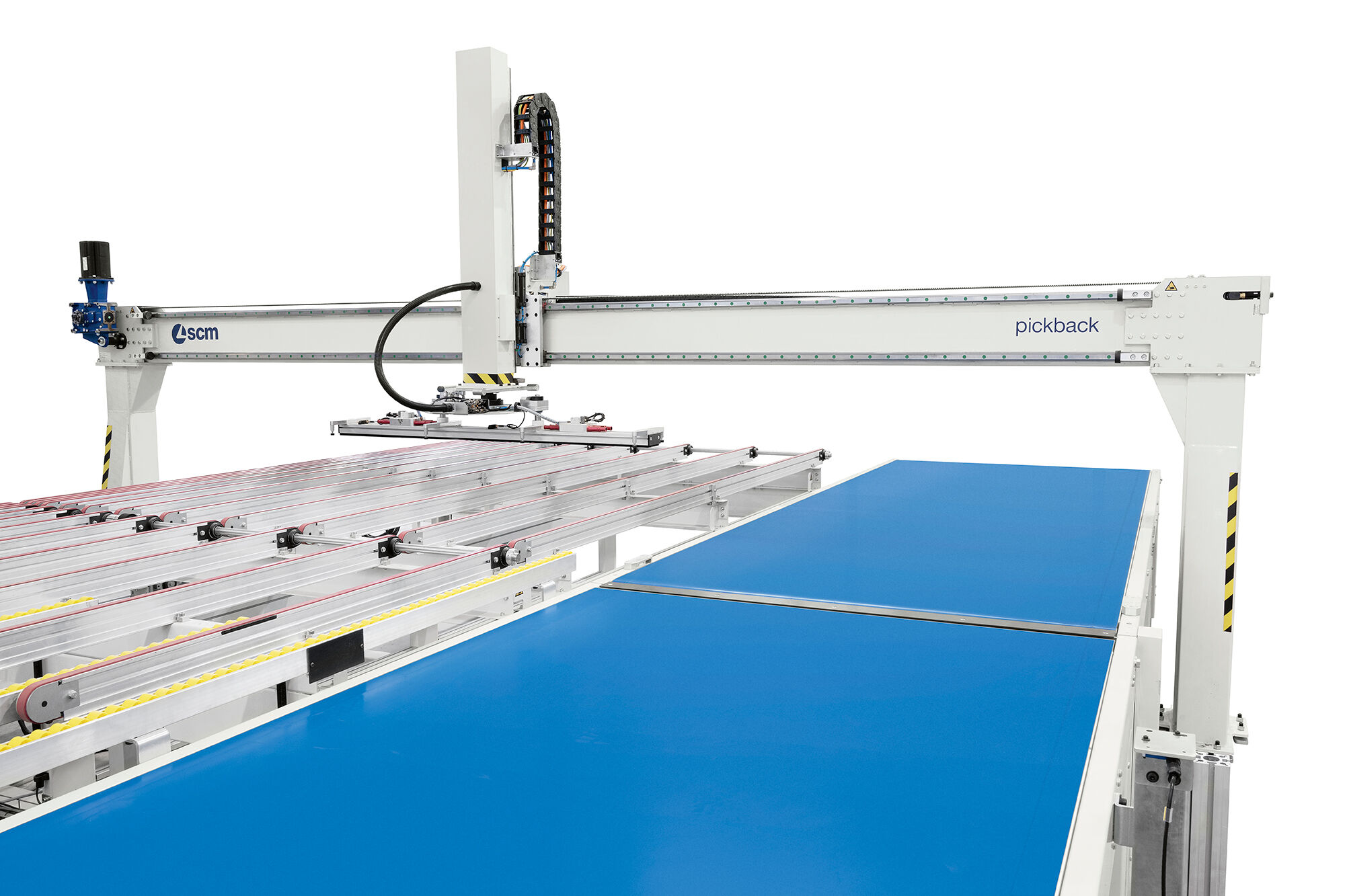

- Modular and efficient: stefani cell S is designed to be easily integrated into different operational scenarios thanks to the integration with the new pickback gantry system. The Pickback system can perform the automatic unloading of the processed panels on a final stack, or on conveying systems to warehouses or other machines downstream of the cell with significant advantages in logistics and processing times, together with complete panel return to the operator.

- Precise and dynamic: Specific technical solutions guarantee the maximum quality in the final assembly of all cabinet parts. Repeatability and machining precision become an indeed added value for all furniture components.

"First-level" cell of the stefani cell range for the edging of panels already squared. It combines the advantages of customised production and large volumes with a compact overall design and an accessible investment even for SMEs. The multiple configurations available satisfy every specific need in terms of productivity and processing. Feeder, robot or additional handling device can be combined to offer maximum flexibility.

This solution is characterised by:

- Simplicity, integration and versatility: the multiple configurations ensure all specific production and machining needs are met. Feeders, robots or additional handling can be combined to offer maximum flexibility.

- New automation to speed up business: the new "pickback" gantry system for the automatic return of the panels guarantees simple, "just in time" production management. This way, the operator can focus solely on feeding the panels back into the edgebander, effortlessly and ergonomically.

- No errors and the guarantee the panels will always be fed in the right direction, thanks to the SIDE FINDER technology, which, via a display in the operator's area, shows how to insert the panel to be correctly machined.

STEFANI ROCKET FOR A LARGE VOLUME "MASS CUSTOMIZATION" PRODUCTION

The stefani rocket range includes flexible edgebanding and square-edgebanding lines composed of two or four single-sided edgebanders and interconnection automation systems for a continuous process with high productivity. The lengthwise and crosswise machining of panels occurs in two passes in lines with two edge banding machines or just one pass, with an intermediate rotation of 90° of the part, in lines with four edge banding machines. The Maestro active watch supervisor for line production management and control can be fully integrated with the existing company information system (ERP) and production management software (MES), creating a bidirectional data exchange.

Solution with two single-sided edgebanders, ideal for guaranteeing a return of the production flow on the same side of the panel's introduction, thanks to its particular U-shape configuration. It also ensures flexibility with high production volumes.

This solution is characterised by:

- Compact layout for a straightforward process of the four sides of the piece in just two passes.

- Easy management of the plant with a single operator for the supervision

- High flexibility in batch 1 production. Processing panels of different dimensions, applying different types of edges, and executing various machining without production downtimes thanks to the working units' fast, automatic positioning.

- TR C180 panel translation system. It allows the use of the two single-sided edge banders also as stand-alone machines with an independent insertion of the panel.

- Possibility of automatic closing of the loop for the second pass by means of specific automation devices.

Edgebanding or square-edgebanding line with two or four single-sided edgebanders arranged in line for a straight production flow with automatic panel introduction and modular automation systems. The line perfectly meets the specific needs of flexible production, wholly automated and with high production volumes.

This solution is characterised by:

- High flexibility for batch 1 production. Processing panels of different dimensions, applying different types of edges, and executing various machining without production downtimes thanks to the working units' fast, automatic positioning.

- Rational layout of the material flow with simplification of factory logistics.

- Production flow always guaranteed by the Moover automation. Once the operator has inserted the panel, its approach and insertion into the machine are entirely automatic.

STEFANI ROCKET E

productivity and flexibility with an investment affordable also to small and medium-sized companies

"First-level" edgbanding line with manual loading for the processing of panels already squared. It is perfect for companies that approach flexible production.

This solution is characterised by:

- Ease of use: the line does not require integration with external management thanks to the many available working modes:

- "Classic" mode with self

- Learning panel dimensions

- Management with program list - Management with Barcode / Qrcode - No errors and a guarantee the panels will always be fed in the right direction, thanks to the SIDE FINDER technology, which, via a display in the operator's area, shows how to insert the panel to be correctly machined.

- High productivity thanks to the ease of the panel insertion system

- Rational layout of the material flow with the simplification of factory logistics

- Moover handling system: Once the operator has inserted the panel, its approach and insertion into the machine are automatic.