Cms smart4cut: simple, intuitive, and professional!

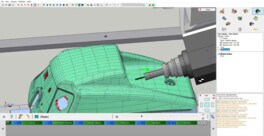

4 Nov 2022smart4cut is the new programming system for 5-axis machining centers to process plastic thermoformed parts.

smart4Cut has a simple and intuitive interface. Proposed on three single or integrable levels, it offers the most advanced programming functions in both self-learning (on the machine or virtually) and CAD/CAM mode.

All the functions are “at the click of a button” and can also be used by those with limited computer knowledge.

Watch the explanatory video

TOP BUYER BENEFITS

- 21% reduction in programming time

- 17% saving on the average thermoformed trimming cycle

- 15% savings on pre-production set-up work on the machine

SMART4CUT LEVELS

Level 1

The application to create self-learning projects directly on the machine, with the assistance of “Cms Teach” digitalization software in combination with the advanced keyboard with joystick and touch screen.

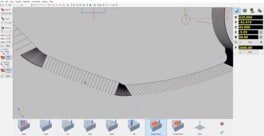

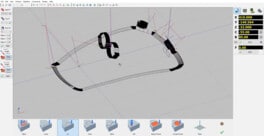

Simple changes can be made to the self-learning paths, (move points, adjust pockets, regulate inclination of axes B and C) and you can also see an easy simulation of the program created.

Level 2

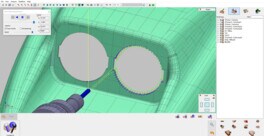

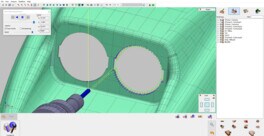

The application for the advanced change of self-learning projects with the aid of Level 1 Smart4Cut and the creation of CAM projects starting from an imported 3D model.

Optimized junctions are inserted between one processing and another and the anti-collision simulation between the piece/template and cutter

Level 3

The application for advanced programming in cutting thermoformed parts, with the assistance of all the functions of an advanced 5-axes CAD/CAM.

It includes the control of 5-axis trim paths, 2D and 3D graphic change functions and the CAM functions dedicated to the world of thermoformed parts trimming and consists of the optimized junctions and simulation with a check on collisions.