The Three Solutions for Plastic Material Processing Experts

28 Mar 2023At CMS, we develop and offer vertical solutions that maximize the performance of our machining centers in any field of use.

To assist experts who operate in the field of plastic materials, we propose 3 base platforms to configure the machining center and maximize return on investment: Nesting, High Performance Plastic Parts, and Knife Cutting Technology.

Nesting

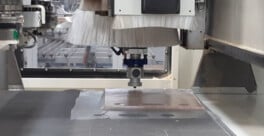

The CMS platform for nesting plastic and advanced materials simplifies and accelerates cutting processes, even the most complex ones, thanks to specific software and hardware solutions.

The stability of the pieces, even the smallest ones, is always guaranteed through:

• High configurable extraction tables with a high level of planarity for maximum precision of vertical removal;

• Up to 30 vacuum zones with dynamic management, essential when dealing with small or breathable pieces;

• CNC-controlled extractor hoods with optimized functioning.

HPP (High Performance Plastic) Parts

The CMS solution for processing High Performance Plastic (HPP) material components allows the machining center to be configured to intensify the potentials of the materials and components in full respect of the strictest processing specifications, thanks to the following characteristics:

• Top-of-the-range precision and repeatability;

• Electro-spindles capable of guaranteeing high removal and excellent finishing;

• A wide range of state-of-the-art support solutions on multifunctional tables;

• Command signals for readily available customized devices.

Knife Cutting Technology

(Oscillating, Fixed and Tangential Blade/Knife Cutting Technology)

Our blade/knife (oscillating, fixed, and tangential) cutting solutions applied to CMS high-performance machining centers are at the core of CMS Hybrid's philosophy, which guarantees unbeatable flexibility of use.

These are specialized solutions that, without ever foregoing the performance, rigidity, and removal ability of our machining center, allow CMS machines to be used in a wide range of sectors, including:

• Poster designing

• Marketing, visual, and shop and trade fair outfitting

• Lighting engineering

• Processing of expanded products

• Processing of elastomers in sheet metal (seals)

• Cutting alveolar and honeycomb sheets

• Vehicle interior outfitting

• Flexible flooring and covering in plastic materials.

CMS's technological solutions, together with constant support from our expert technicians, guarantee our clients' success.