Maintenance is an ally not a nightmare for wet finishing!

23 May 2022Maintenance is an ally not a nightmare for wet finishing!

The wet flexible belt technology is most definitely the best technical solution for all those high-quality surface finishing requirements on ferrous and non-ferrous materials; as is the cleaning of surfaces which require a considerable amount of material removal.

One aspect that needs to be taken into consideration, when approaching wet deburring, is machine maintenance and cleaning, especially if compared to traditional dry machines. Lack of regular and appropriate, maintenance can compromise efficiency, resulting in frequent machine downtimes and service intervention.

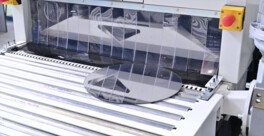

CMS designed and built the new dmc m950 wet M6 with the objective to ensure both simplicity and accessibility, to make cleaning and washing a fast, efficient operation that ensures top quality and performance over time, and work uniformity as well.

MAIN FEATURES

- Configuration from 4 to 6 operator units to increase productivity and deal with the most demanding part processing

- Removable inspection hatches between the operator units to clean the system faster and more efficiently

- Removable rolling front shutter and side panels to wash the collection tank.

- Steel frame with electrolytic zinc plating and stainless-steel paneling to ensure greater protection over time against corrosion

- Anti-ejection outgoing motorized roller (patent pending), to guarantee maximum safety for the operator when processing metal sheets of any shape