SCM at Interzum Guangzhou

28-31.03.2021 Guangzhou (China)

SCM'S “SMART&HUMAN FACTORY” TAKES CENTRE STAGE AT INTERZUM 2021

SCM confirms it will be taking part in Interzum, China's number one wood machining trade fair.

Come and find out more about SCM's Smart&Human Factory: the new model of digital factory, automated and personalised to satisfy your real production requirements.

You'll have a chance to discover all the latest products that SCM has in store for businesses on the Chinese market with two key aims: optimise and simplify production processes, including the most flexible machinings, and achieve a top quality product.

Cell for "batch one" production

At Interzum, you will get a clear idea of automated solutions, custom-designed by SCM for the Chinese furnishing and design market.

Taking centre stage is the flexible cell designed and developed for "batch 1" production of furniture components, with a maximum output of 800 panels per shift.

The key advantages? Extreme machining flexibility, a fixed and just in-time production flow and an excellent end product quality, thanks to the special features of the technological solutions on display.

Beam saw

All the benefits of the gabbiani s sizing machine are highlighted:

- up to a 30% increase in productivity with the FLEXCUT 1s unit for simultaneous longitudinal and transversal cutting;

- fast, accurate tool setting with the SAW-SET device;

- maximum precision even on more complex longitudinal cuts thanks to a special device for panel de-tensioning cuts;

- maximum loading capacity thanks to the lifting system that is always parallel to the stacks of panels.

In the special configuration on display at Interzum, gabbiani s is integrated by a 30 level vertical magazine for storing pieces between the beam saw and edgebanding processes.

The magazine acts as a "plenum", given the high speed at which the sizing machine operates, with the advantages of keeping the production flow steady between the two processes.

Edge banding

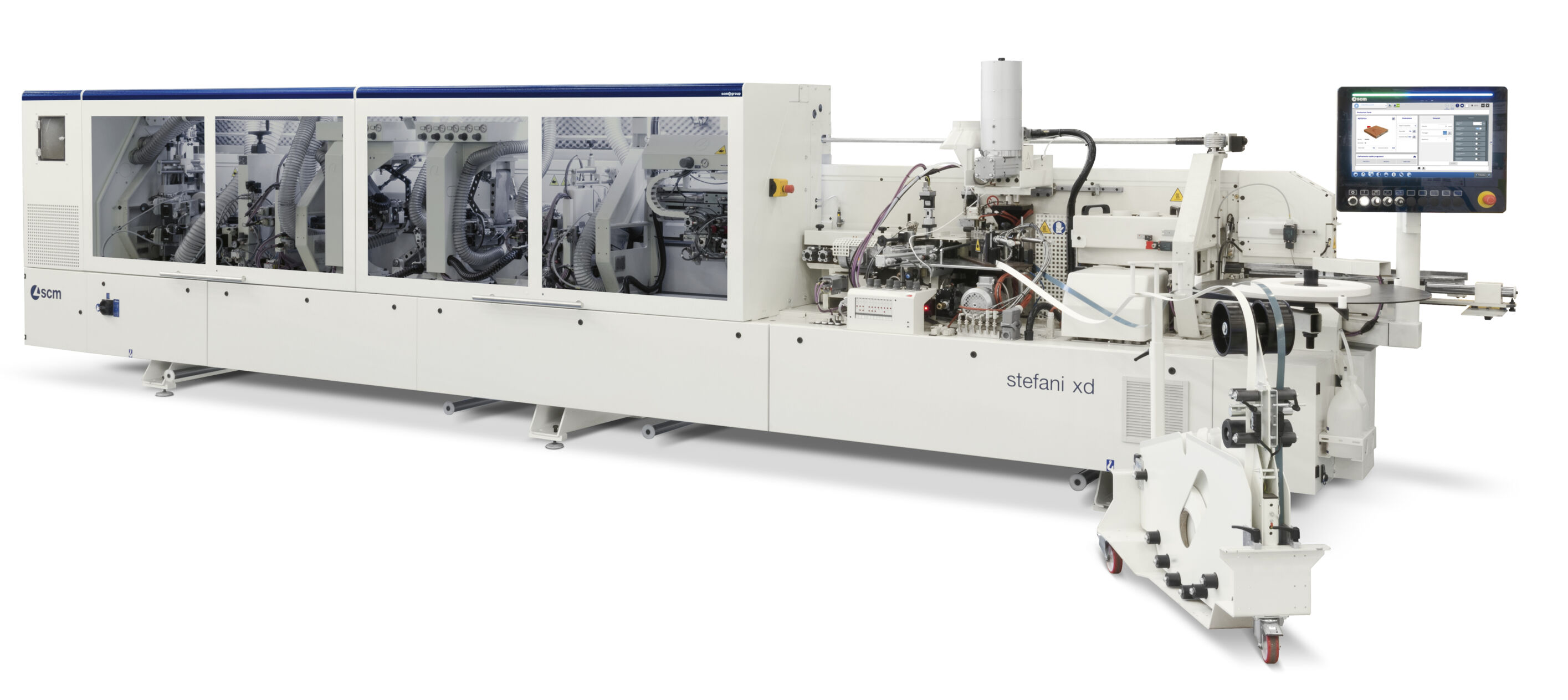

stefani xd key player, the most up-to-date summary of SCM's high technology for industrial edgebanding:

- the ideal solution for the production of parts for furniture with the most advanced designs and use of the latest trending materials.

- surprising finishing quality thanks to the AirFusion+ technology that allows you to edge without glue, making the joint between the edge and panel invisible.

- maximum versatility: all the panel's parameters can easily and rapidly be changed (type, colour, edge thickness, position and depth of the mortise, management of the protective film, panel dimensions....) without ever interrupting the production flow.

The edgebanding machine is integrated by an industrial articulated robot for the automatic loading, re-introduction and unloading of the panels.

A further guarantee of optimisation and simplification of the process is given by the software coordinating the robot's work:

- on exiting the vertical magazine, all the information about the panels (sizes, colour, materials etc.) can be acquired thanks to the software, by reading the QR code;

- the same information is used by the software to coordinate the robot and edgebanding machine during the various passages through the machine to unload the pieces.

SCM Surface technologies

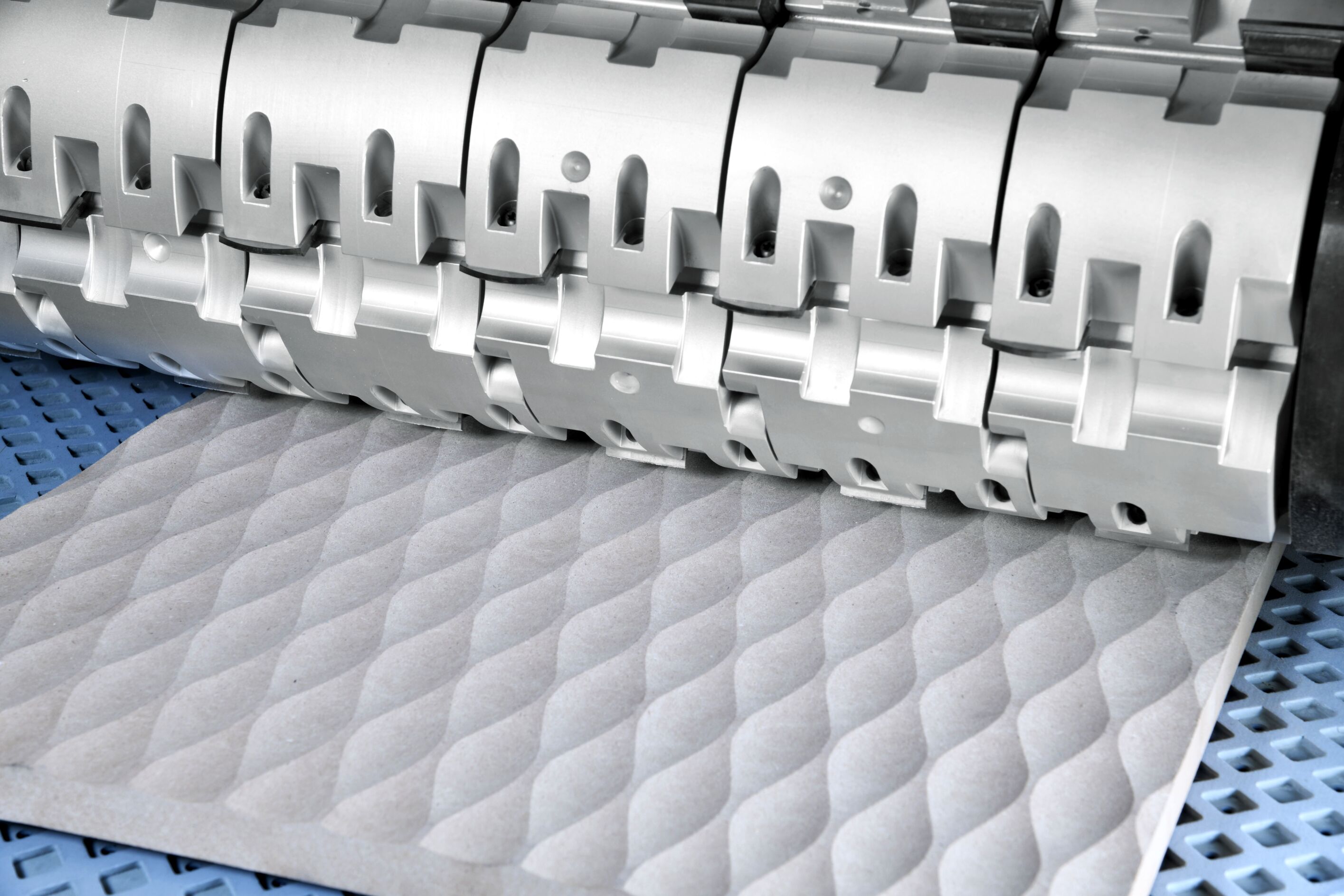

Discover the ultimate turnkey scm surface technologies solutions for 3D surfaces processing, dedicated to companies operating in the flooring, wall cladding and modern furniture sectors.

For the first time on display a 3D surfaces space exclusively designed and entirely realised by SCM Surface technologies.

The extremely versatile dmc wide-belt sander with its exclusive carving unit, in tandem with the superfici compact R spray machine and the patented superfici excimatt system, maximizes excimers technology to deliver a superior "soft touch" and fingerprint resistant finished 3D surface.

Together with sanding and spraying technologies it will be possible to see products produced by sergiani 3d form hp press, with membrane or membrane-less processing cycle for high productivity.

Other technologies

morbidelli m200

The “morbidelli m” range confirms itself globally as the benchmark for CNC machining centres. Thanks to its solid structure, the 250 mm piece transit, the 5-axis Prisma KT and the Flexmatic work table, morbidelli m200 can perform not only every kind of panel machining, but also those for solid wood.

At Interzum morbidelli m200 will be equipped with a special application developed in collaboration with Lamello AG, to offer a one-hit machining process that gives a quick and cost-effective way to work with 90-degree butt joints without the need for glue.

No second machining is required: the whole process can be completed on a single machine with high levels of speed and accuracy.

stefani md

Also in evidence stefani md, the perfect edge bander for all companies who require continuous production of a large number of panels even though they are all different from one to another. High productivity and extraordinary level of finishing quality find in this model a perfect combination. Perfect joint line and great versatility of use are guaranteed by the "SGP" glue pot which allows you to use both EVA and Polyurethane glue with a top gluing quality. The range has a new look even on the software side with Maestro active edge for error free usage and maximum performance.