Urban Quarry chooses CMS

stone

Urban Quarry: Industrial and market reference in Canada and North America for the production of natural stone kitchen countertops and interior design

Passion of the owners, competence of the staff and technological choices coherent with the demands of a growing market, all aimed at achieving a product of excellence.

The specialist expertise of Urban Quarry in the field of countertops processing and architectural elements in natural stone has its basis in the entrepreneurial spirit of the founder, Laurent Bellavance, who, since 1986, devoted himself to this activity both passionately and exclusively. The original team has grown to place itself on the Canadian and North American market as a reference in its sector.

Currently Urban Quarry is set up as a “product-oriented” company that has been able, however, to open itself up to the most advanced marketing and to the ability to transform their identity: going from “good service provider” to partner in all of its customers’ goals, and has become the recognized leader in product quality and design.

The development of Urban Quarry, in terms of level of working volumes and prestige, even won out against its most demanding market counterparts, is the result of an ability to combine the typical professional attention for the detail with the use of the most advanced and reliable technologies. Consistent with this principle the company has also quickly strengthened cooperation with CMS, whose work centres are

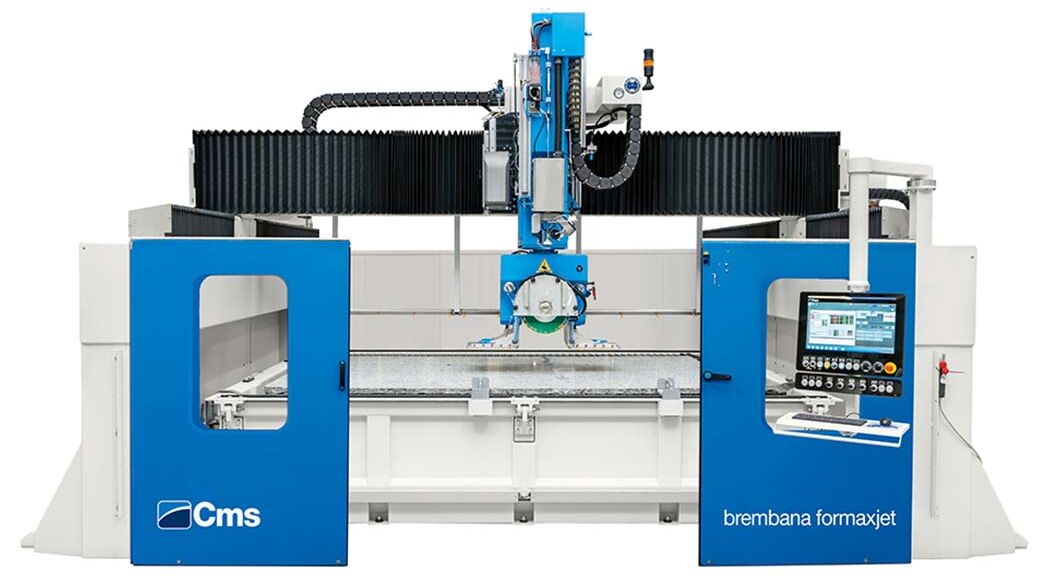

considered by Urban Quarry as the technological excellence at the international level and the ideal solution to their needs. This synergic relationship is reaffirmed by the fact that the productive chain in both cutting and finishing, within the establishment of Urban Quarry, is totally entrusted to CMS machines, where six CNC machines process natural quartz surfaces.

Urban Quarry’s inspiring concept of diligence has always been to “make the best products easily available to its customers”; in other words, the aim is to make the quality and beauty of stone available while avoiding issues and concerns for their representative business partners.

In 2016 the company moved to new premises, which are larger and more modern, but still in Ottawa. The highlight of the plant is the new showroom which displays some of the most interesting and valuable achievements made by Urban Quarry staff. Not only to make their own kitchen tops, which still remain the main acitvity of the company, but also pieces for bathrooms, for fireplaces and for several other

architectural applications.

The relevant technological investment made recently by Urban Quarry, which has led the company to develop a new high-efficiency fully equipped department with CMS working centres, also stems from the highly competent and professional advice provided by Drolet Machinerie Inc., the technical and commercial managers from Drolet Machinerie were helping the Bellavance family and its team to exactly understand the many benefits of CMS machines and the reasons that make them the

point of reference in the manufacture of floors, and both natural and composite stone pieces, on

an international level. They then figured out the configuration and the evolutionary development plan of the department together with the customer, providing a schedule that has proven itself to be optimal. They also placed the management and engineering teams from Urban Quarry in contact with the staff from CMS headquarters, creating the best conditions for a working dialogue. The excellent operating results that Urban Quarry is achieving with its new machining centres are reasons of the highest professional satisfaction on the part of Drolet Machinerie.

Urban Quarry (Canada)

A production chain with six working centres CMS Brembana for the processing of natural and composite stone

urbanquarry.ca

Fill out the online form to be contacted by a salesperson