Lamiera 2017

17-20.05.2017 Milano, Italy

SCM at Lamiera 2017, the international exhibition dedicated to the metal forming machine tool industry

Visit us at Hall15 Booth F26 G23

The complete range of dry and wet deburring/graining machines for metal surfaces, thanks to the latest generation of DMC technologies, is able to respond at best to any application, from the removal of large sharp burrs to surface finishing on Mild Steel, Stainless steel, Aluminium and Titanium.

Introducing at Lamiera the new eurosystem md dry deburring and finishing machine for metals

Advantages

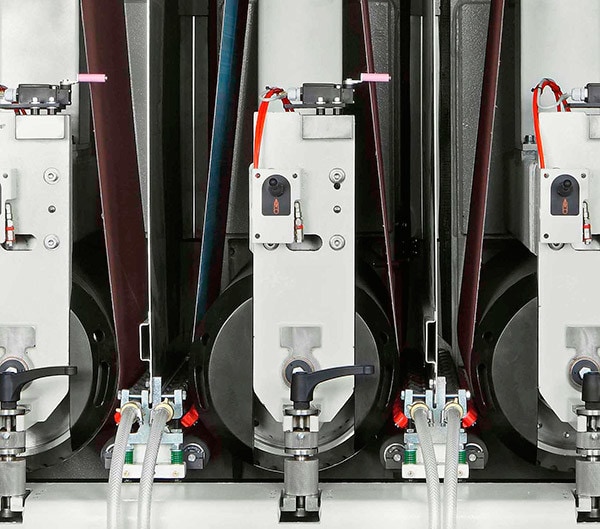

Contact roller unit for very high quality finishes

Topmetal contact rollers are available with a diameter of 250 mm or 320 mm. The latter, thanks to the larger contact surface with the work piece being processed and greater ability to absorb any defects on the abrasive belt joint, are specifically indicated for all applications requiring very high quality finishes.

Modular structures for maximum customization

The modular structure of the machine along with the newly designed working units allows for maximum flexibility within the machine in order to meet the changing needs of production. In fact any single working unit can be replaced quickly and economically (or their placement inside the machine can simply be changed thus changing the composition of the machine).

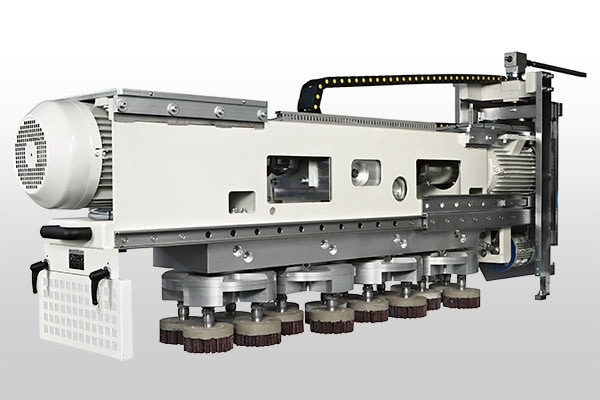

Planetary unit with disc brushes, innovative design for excellent production performances

The innovative DP Planetary unit was developed by DMC in response to the demand to the more complex needs of deburring and rounding of work piece edges. All of the motor transmissions in the unit are driven by sprockets sealed and constantly lubricated (NO DRIVE BELTS ARE USED!), thus ensuring the unit is capable of working with high speeds or when working 3 working shifts per day. These exclusive construction features of the unit guarantee high levels of reliability as well as minimal noise levels during operation.