Maximum precision and flexibility: discover the benefits of automatic TCP measurement!

Jan 18, 2024CMS waterjet cutting technology offers tremendous benefits in terms of flexibility and ease of use and is a winning solution in metal alloy, composite and plastic cutting applications.

The 5-axis configuration can perform precision mechanical machining, dynamic water jet compensation, and edge caulking for welding.

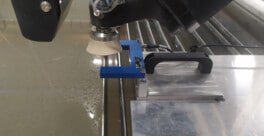

To ensure the cutting process is repeatable, CMS offers a TCP and focal distance laser measurement device on the 5-axis head.

The TCP, or Tool Center Position, identifies the intersection error between the C-axis center of rotation and the B-axis center of rotation. Calculating this offset correctly is essential to ensure high-precision cutting with a 5-axis head.

TCP measurement is available in two variants:

-

Retractable and fully automatic on the CMS tecnocut proline model, which reduces tooling and measurement times;

-

On an external tray for manual positioning on the cutting table, which is specially designed for all other models in the range.

Benefits of the TCP automatic laser measurement system:

-

Accurate measurement by a laser sensor;

-

Complete protection from abrasive and water reverberation;

-

Fast acquisition process;

-

TCP table stored directly in the NC of the machine in order to apply the correction offsets to the B- and C-axes;

-

Acquisition of TCP, cutting focal distance and prober errors in a single step;

-

No machine downtime due to the traditional manual TCP error measurement with trial cuts;

-

Simpler management of cutting programs when using multiple CMS machines.