Plastics have become ubiquitous in nearly every industry, in part due to the impact of the thermoforming plastic machining process. Thermoforming involves the use of heat and pressure to create new products. The use of this technology has been incorporated by companies around the world to create reliable, durable goods at low costs.

Thermoforming Overview

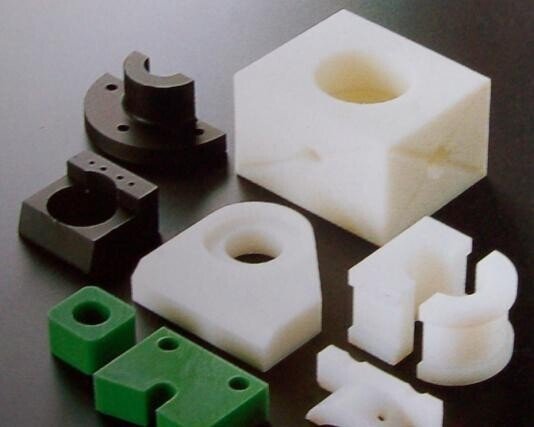

Thermoformed products are created using CNC machines, which utilize a three-step process. First, a flat sheet of plastic is heated, then the sheet is placed in a mold and is finally trimmed. The types of plastics used in thermoforming are nearly as varied as the products themselves and include synthetic, semi-synthetic, or natural materials. The majority of plastics are made from petrochemicals, but those made from plant-based materials, or bioplastics, are becoming increasingly common due to their sustainability.

Thin-gauged plastic products include items like disposable cups, storage containers, plates, and many other products used in the food and medical fields. Thick gauge materials include products such as vehicle panels, refrigerator and shower liners, and shipping pallets.

Some of the many industries that have harnessed the potential of CNC plastic machining include:

Automotive Industry

Thermoforming is used most often in the automotive industry for creating items like vehicle doors and interior panels, such as dashboards. Multi-axis cuts with thermoforming CNC machines are typically required for compatibility with the additional parts used in automobile construction.

Building Industry

The building industry utilizes a broad range of thermoformed products in the construction of homes or businesses, including HVAC components, shower stalls, and more.

Medical Industry

Products often used in the medical industry include storage units and covers for contaminated items, bezels, and instrument enclosures. Thermoplastic polyurethane (TPU), for example, is often used in the industry as sterile packaging to ensure the integrity of medical products.

Aerospace Industry

The aerospace industry uses thermoformed products for the creation of seat backs, interior panels, and instrument coverings. In an industry that relies heavily on weight, plastic parts are an ideal lightweight building component.

CMS North America provides CNC machines and resources to meet a variety of plastic machining objectives, including thermoforming machines. Contact them for more information on the benefits of CNC machining center technology.