Discover the full range of CMS technologies for the processing of composite materials!

4 Mar 2024CMS provides customers with a comprehensive machines lineup and innovative manufacturing solutions to enhance customer productivity and business sustainability.

CMS Advanced Materials Technology and Bercella srl, a leading Italian company in the field of composite materials for aerospace, defence and motorsport applications, have worked together on a project aimed at showing the effectiveness of their technological solutions, with a focus on high know-how in the production of composite materials and equipment.

The manufactured piece is an antenna reflector for radar surveillance systems. It is a piece with sandwich structure composed of 2.74 mm carbon fiber leathers with 0/45/45/0 arrangement and internal core in aramid honeycomb with 20 mm thickness.

Hybrid solution for large format 3D printing

Additive production of the laminating mould in polycarbonate filled with carbon fiber for the realization of composites in autoclave. The process, combined with milling, guarantees material savings of up to 60% compared to traditional technologies.

Cutting with ultrasonic technology

Ultrasonic cutting of aramid honeycomb cores with 4.8 mm cells. This solution allows processing with angles up to 70 degrees.

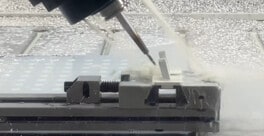

Trimming and milling composite components

Trimming and milling of sandwich structure on a 3D printed subpiece in ABS reinforced with 20% carbon fiber.

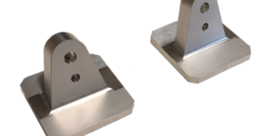

Aluminum milling

Solid machining of aluminum inserts for support and orientation of the antenna.

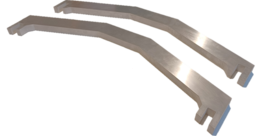

Cutting with waterjet technology

Manufacturing of the antenna supports by waterjet cutting of 20mm aluminum plates.

Discover CMS innovative technologies and machine range at JEC WORLD 2024 in Paris from 5 to 7 March!

HALL 5, BOOTH N58