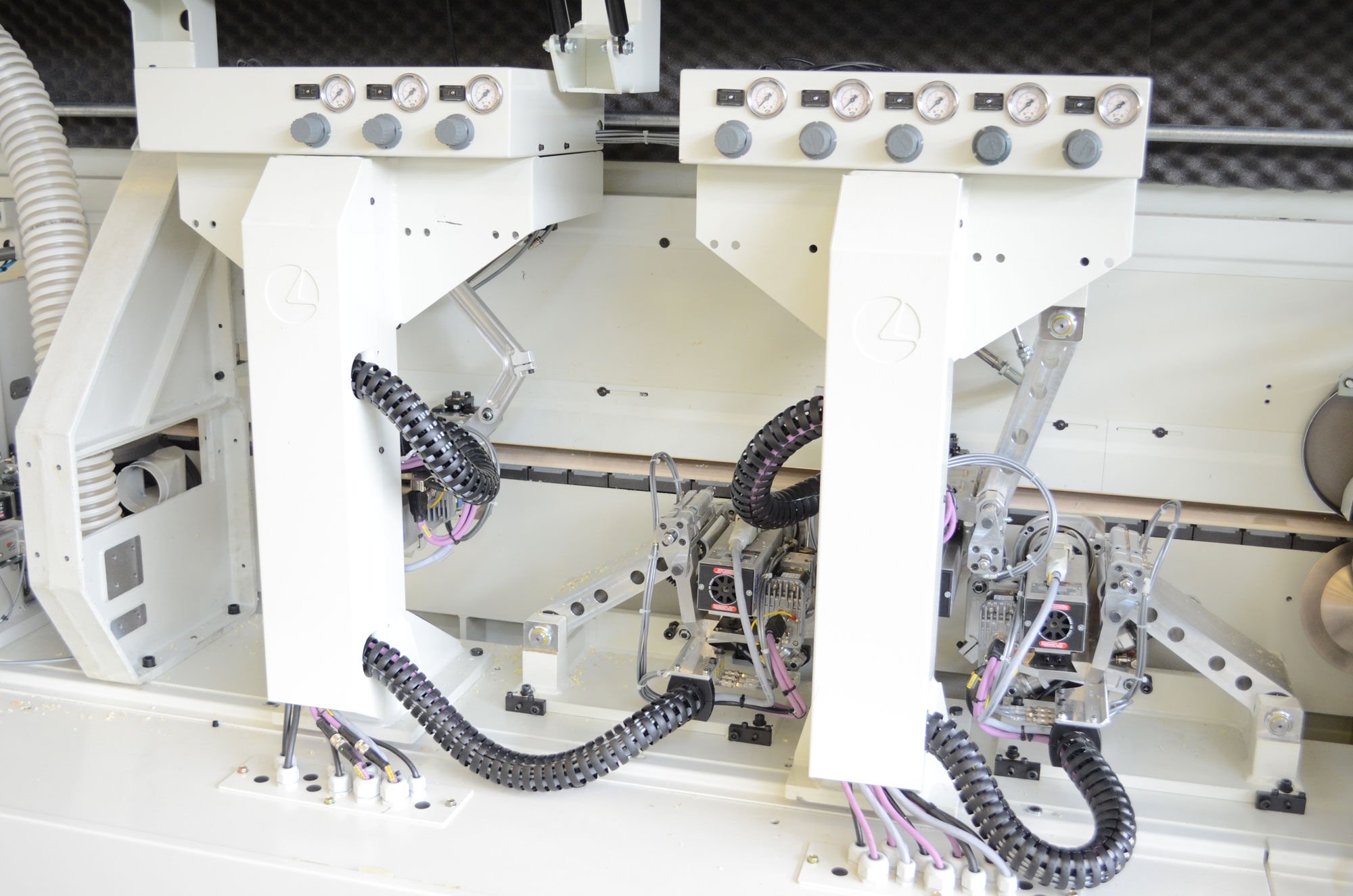

The new trimming, chamfering and edge-scraping units now have a more rigid design with 55% lighter supporting structures and dynamic parts for high quality processing that respects the characteristics of the panels, particularly the more delicate ones. Shorter production times are now possible thanks to the many new devices, for example NestingLock that allows the processing of panels with holes for hinges in a flexible way and without machine downtime, reducing the time for set up from 25 to 0 minutes, compared to the previous version.

The new 4-motors rounding unit has been redesigned to be more rigid, lighter and with higher performance. Now available with rounding speed up to 30 m/min for panels with a thickness from 8 to 60 mm. Zero setup time for up to 3 radii, zero setup time for the micro adjustments with the new AFS device for adaptive copying, maximum simplicity in the processing of panels even with edges with film coating , thanks to the new lateral rotating copying devices.

"Designing" the quality of joint between edge and panel is now possible with the new “SGP” glue pot equipped with NC controlled dosage, the new “PU BOX L” premelter complete with CFS technology that prevents aging and decaying quality of the glue, and the “AirFusion”device for zero glue line that allows the edging without the use of glue.

And more…

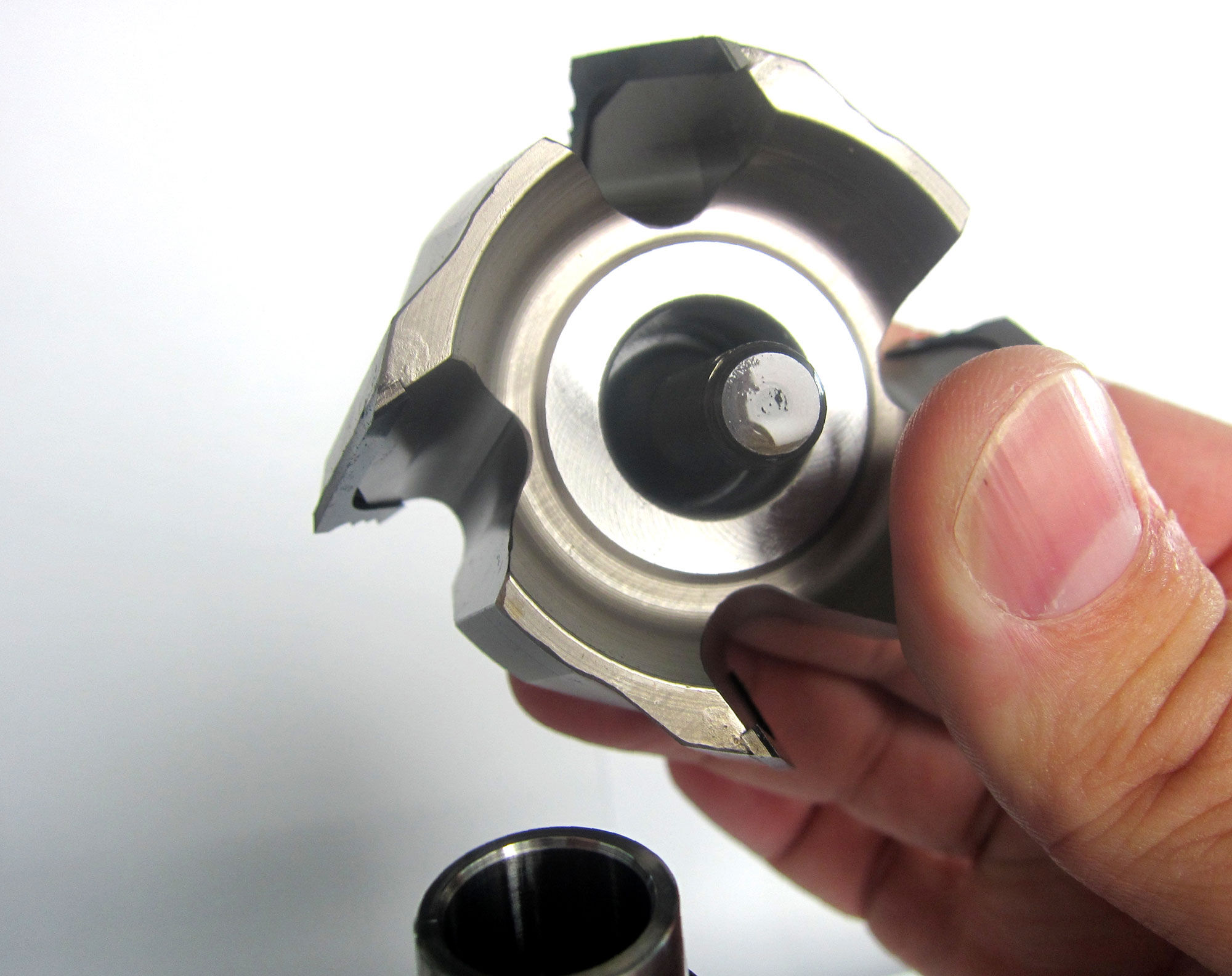

Excellent edge finish quality is possible due to the elimination of vibration caused by backlash in the connection between motor and tool , thanks to Zero Lock, the new tool / motorshaft interface. Zero lock allows, in addition to an ultra-precise coupling, a 20% increase in tool life and a 15% reduction of the noise.